Vertical type integrated thrust vector testing device

A thrust vectoring and testing device technology, applied in the field of measurement and control and sensing, can solve the problems of low accuracy of horizontal structures, and achieve the effects of high accuracy, accurate testing and good structural manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

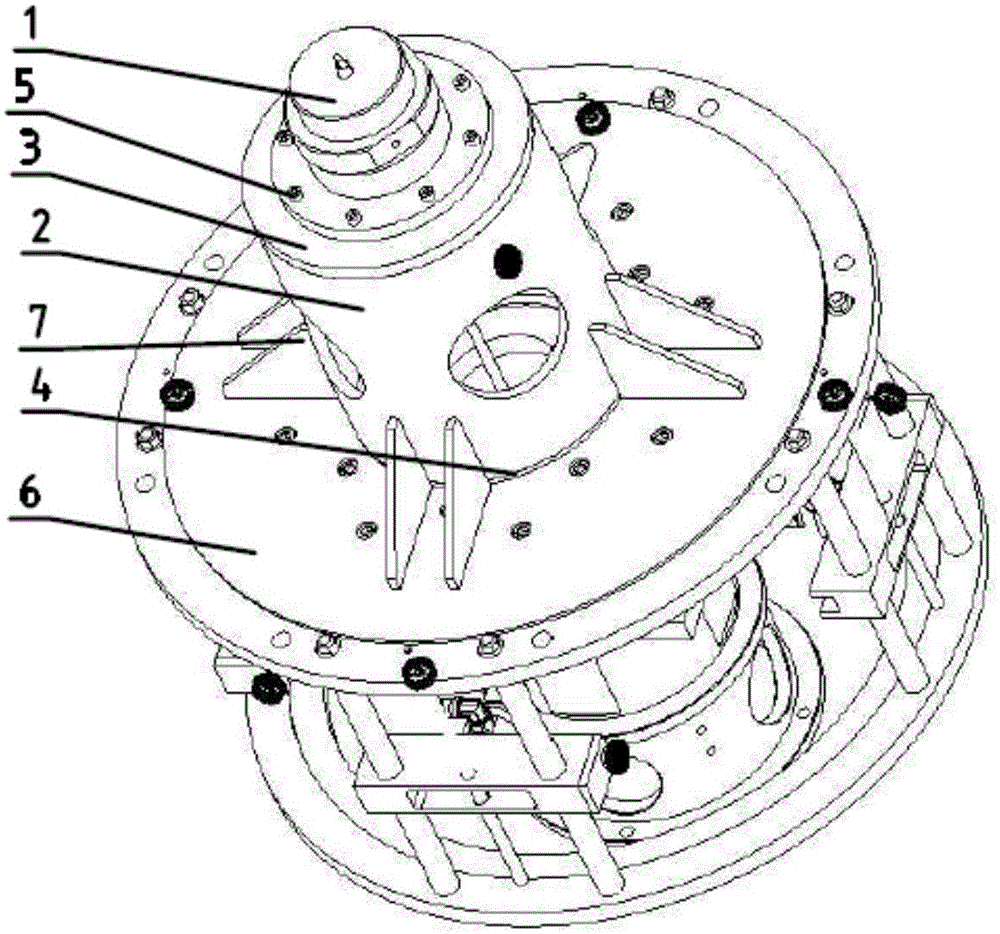

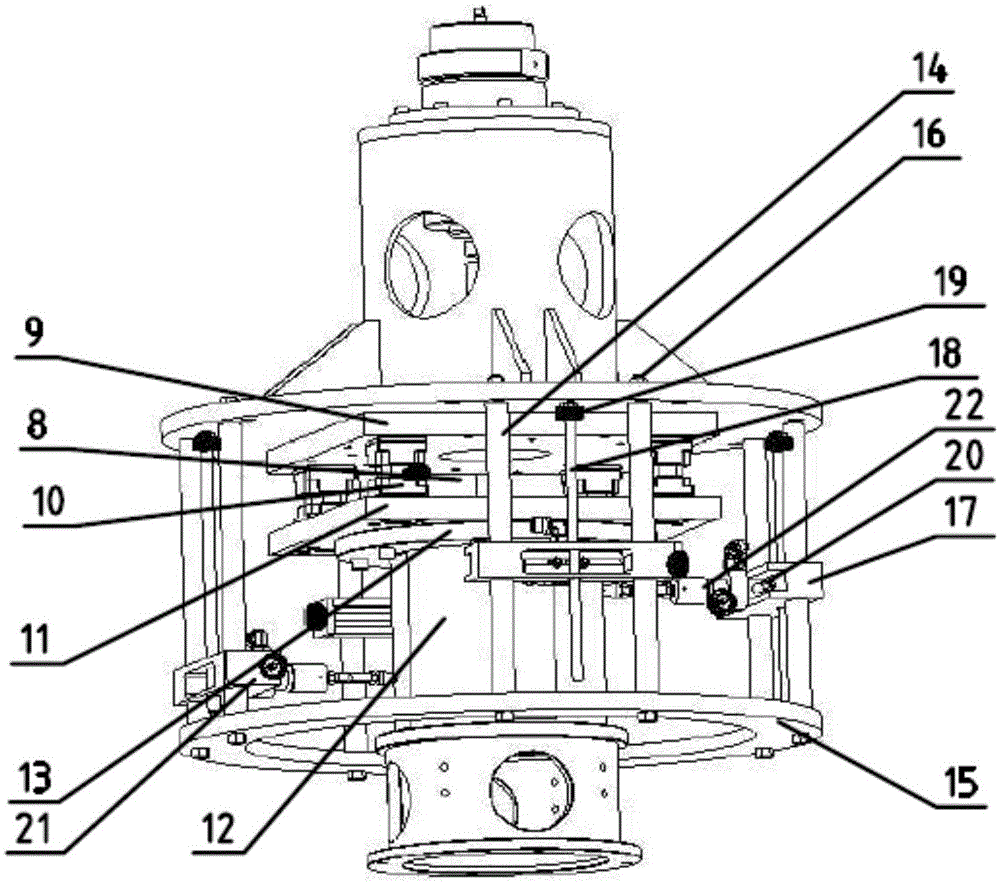

[0011] The implementation of the present invention will be described in detail in conjunction with the technical scheme and accompanying drawings. Such as figure 1 , figure 2 As shown, the upper and lower ends of the upper cylinder 2 are respectively welded with an upper connecting plate 3 and a lower connecting plate 4, the upper end of the upper connecting plate 3 is fixedly connected with the axial force loading unit 1 through a number of hexagon socket bolts 5, and the lower connecting plate 4 The lower end is fixedly connected to the upper disc 6 through a number of hexagon socket bolts 5. There are 4 sets of 8 reinforcing ribs 7 arranged between the upper cylinder 2 and the upper disc 6. Arranged axially symmetrically, the dynamometer 8 is installed between the upper disc 6 and the small disc 13. The dynamometer 8 consists of four three-way piezoelectric quartz sensors 10, an upper titanium plate 9, a lower titanium plate 11 and several inner hexagonal Composed of bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com