Novel digital servo hydraulic cylinder

A digital servo and hydraulic cylinder technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of complex structure of CNC stepping cylinders, high precision requirements of servo valves, and high cost of ball screws, and achieve simplified structure and good speed stability. , the effect of improving the anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

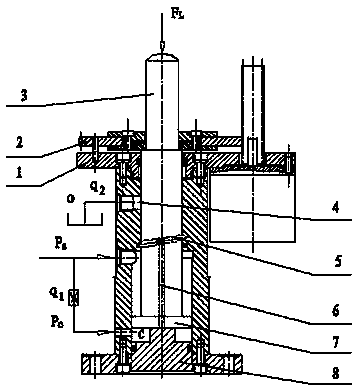

[0010] Such as figure 1 As shown, a new type of digital servo hydraulic cylinder includes a cylinder barrel 1 and an upper cover 2, the upper end of the cylinder barrel 1 is provided with an upper cover 2, the cylinder barrel 1 is placed on the left side of the piston rod 3, and the left side of the piston rod 3 is set There is a bow-shaped return throttle 4, and a triangular spiral oil passage 5 is provided on the inner wall of the oil cylinder at the lower end of the bow-shaped return throttle 4, and a return throttle 6 is arranged at the center of the lower part of the triangle spiral oil passage 5, and the return throttle 6 is arranged on the plunger 7. The lower end of the plug 7 is provided with a chassis 8 .

[0011] Two axisymmetric small holes are offered on the described dialing piston rod 3 .

[0012] The center on the said dial piston rod 3 is provided with an oil return hole.

[0013] It works as follows:

[0014] The high-pressure oil Ps passes through the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com