Welding thermal cycle curve test device and application method thereof

A welding heat cycle and testing device technology, applied in the direction of measuring devices, welding equipment, welding accessories, etc., can solve the problem that the imaging speed cannot meet the temperature change rate of the welding heat cycle, the joint between the thermocouple and the test board cannot be observed, and the measurement of the test area The position is difficult to control and other problems, to achieve the effect of ensuring authenticity, accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0053] As a certain specific embodiment of the present invention is as follows:

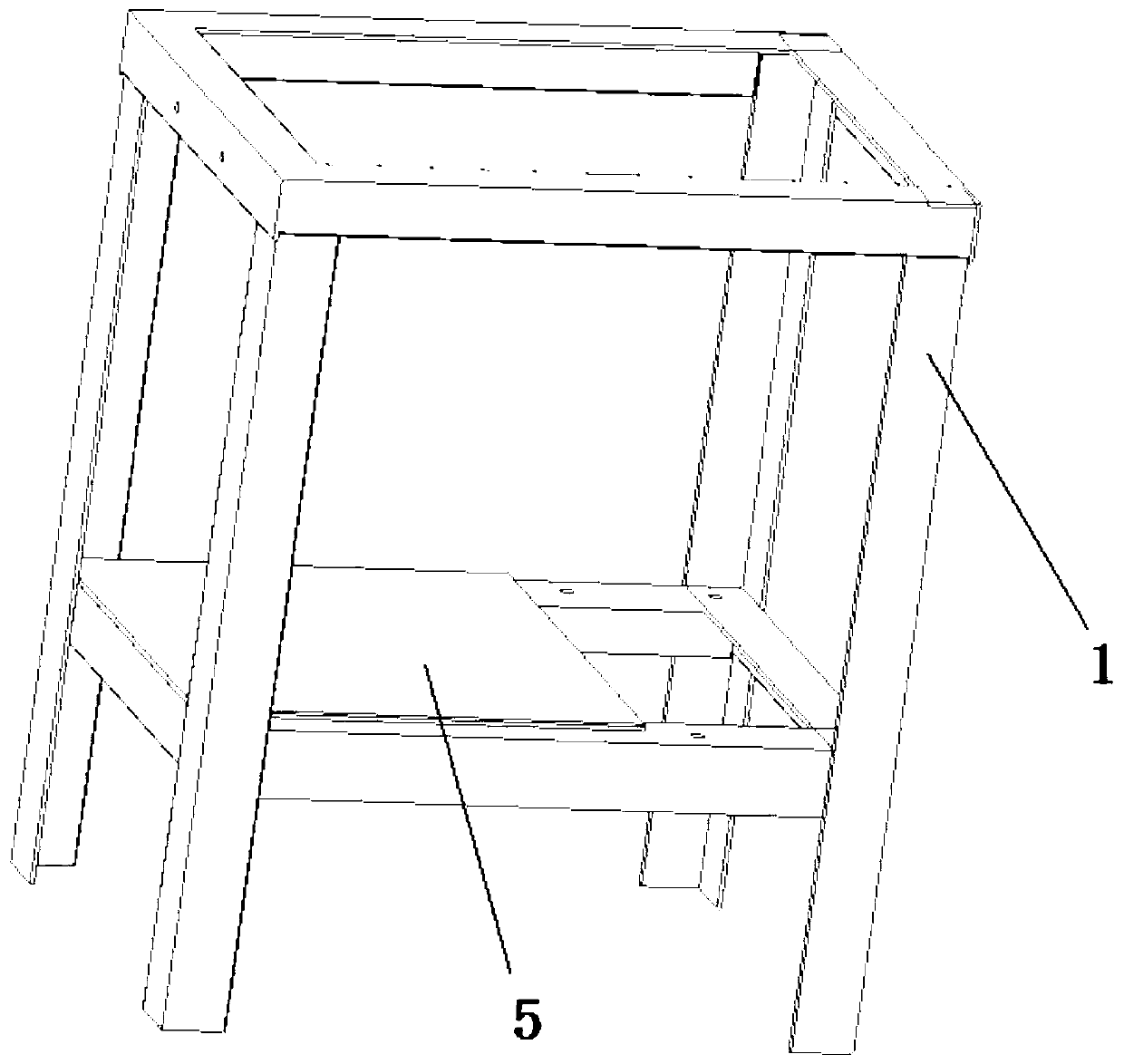

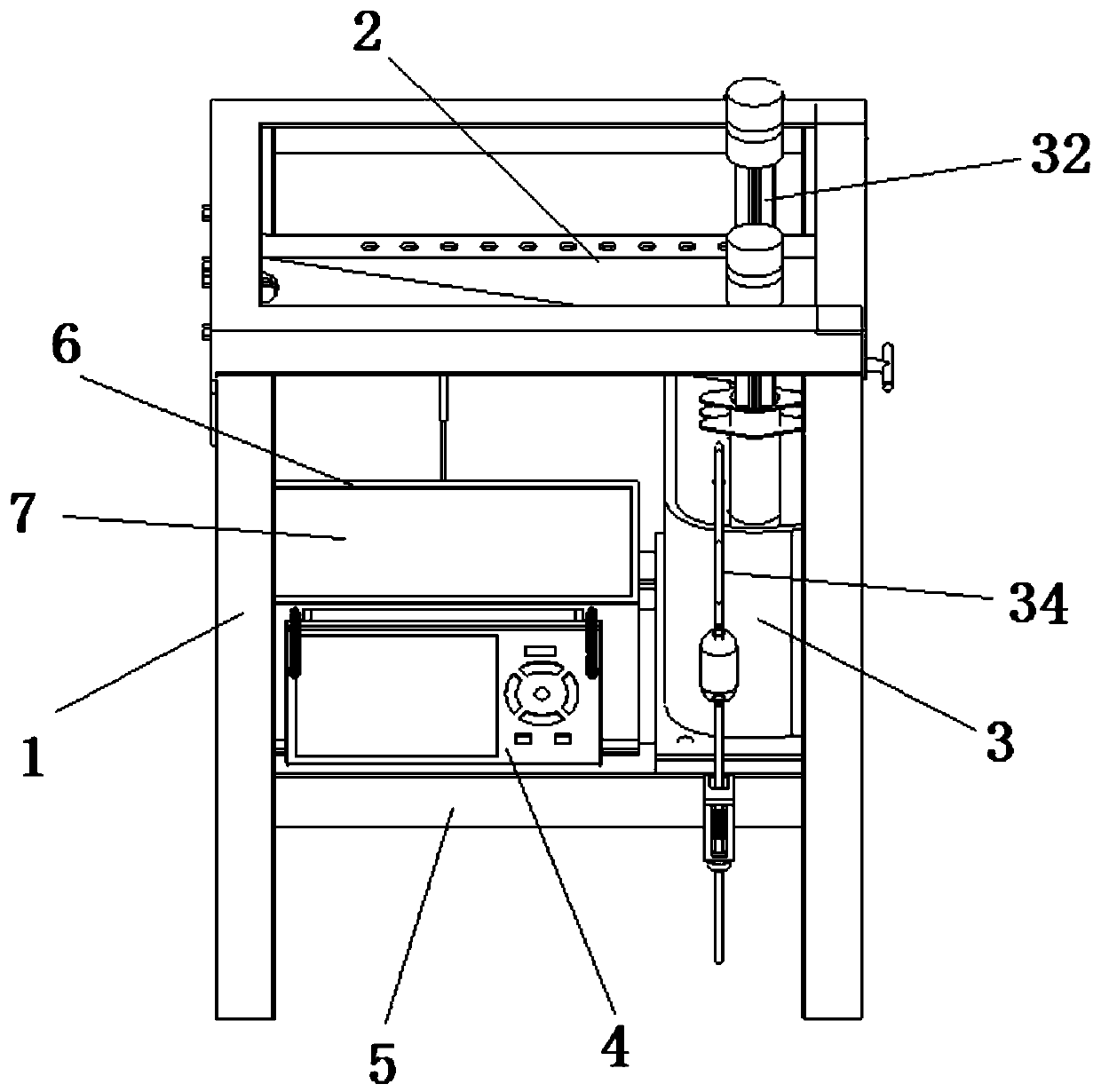

[0054] The support frame 1 is mainly composed of Q235 angle iron, which is connected by means of welding processing. Specifically, it is a frame structure with a height of 402mm, a width of 232mm, and a length of 330mm. The four threaded holes on the side are used to connect the clamping device 2 to the support frame 1. The mounting plate 5 is mainly used as the support of the test system, and the threaded holes on the mounting plate 5 are mainly used to fix the components, and the connecting bolts adopt four standard bolts and nuts of M5×20. The required bolts and nuts are very easy to get at hardware parts stores or Taobao, and the price is cheap.

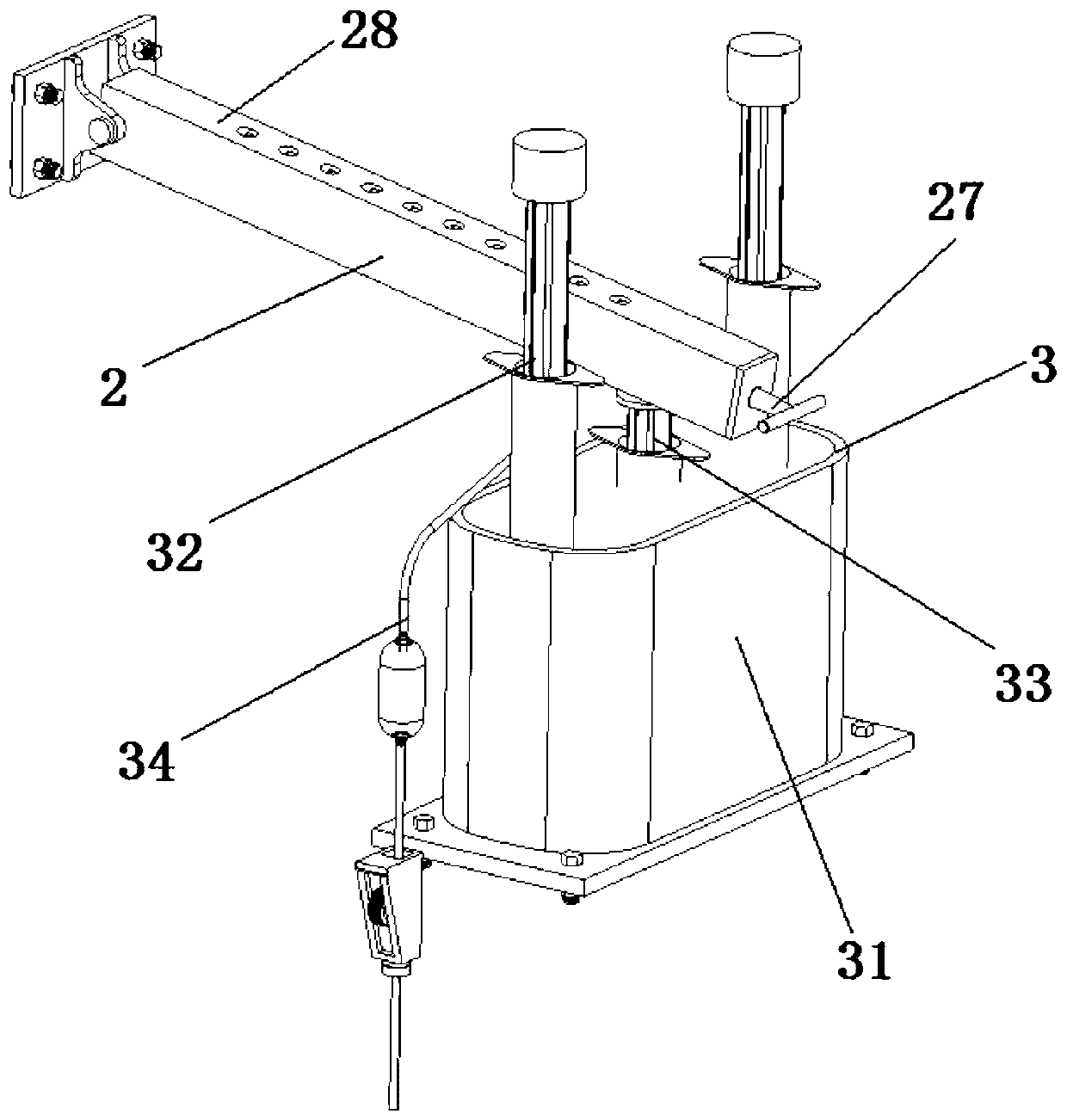

[0055] The clamping device 2 of this embodiment is used to clamp the thermocouple sleeve with a diameter of 4mm. From the perspective of practicability, 10 baffle plates with cylindrical surfaces are designed in the first clamp shell 21 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com