Device and method of measuring infiltration performance of porous metal material on the basis of digital image processing

A technology of porous metals and measuring devices, applied in measuring devices, analytical materials, instruments, etc., can solve the problem of inability to quantitatively evaluate the infiltration uniformity, and it is difficult to realize the comprehensive, accurate and quantitative research on the infiltration performance of porous media materials, which cannot be comprehensive Reflect the infiltration quality of porous media materials and other problems, and achieve the effect of solving incomplete measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

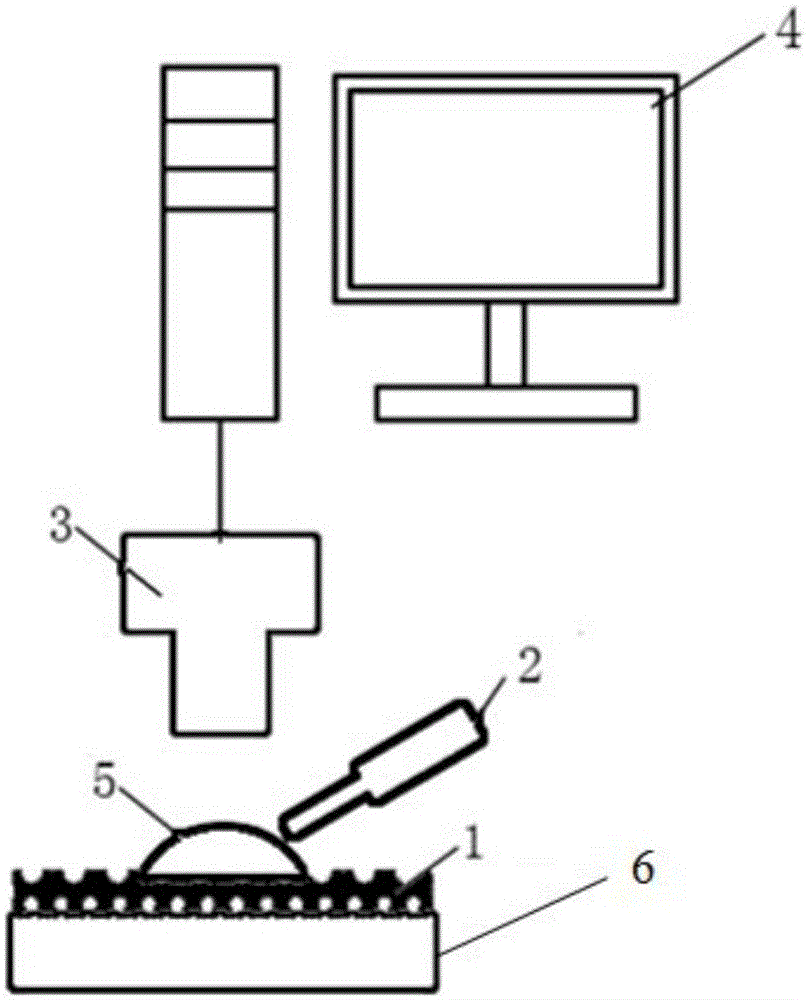

[0035] Combine below Figures 1 to 11 Specific embodiments will further specifically describe the present invention in detail.

[0036] (1) prepare two kinds of electrodeposited porous copper films with different process parameters, and their process parameters are respectively:

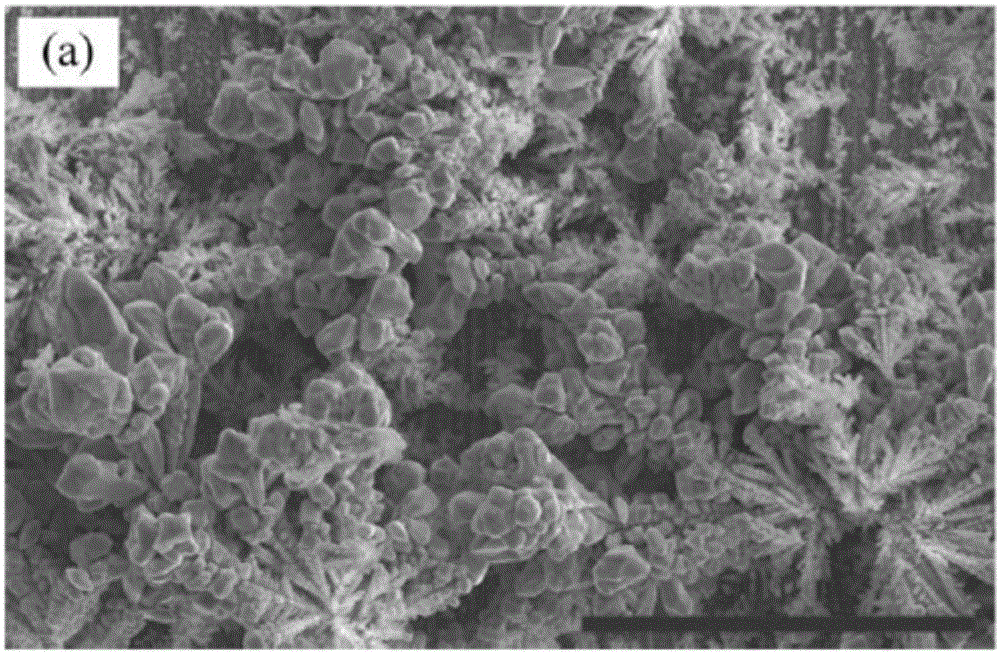

[0037] figure 2 In, A sample: current density 0.1A / cm 2 , deposition time 150s;

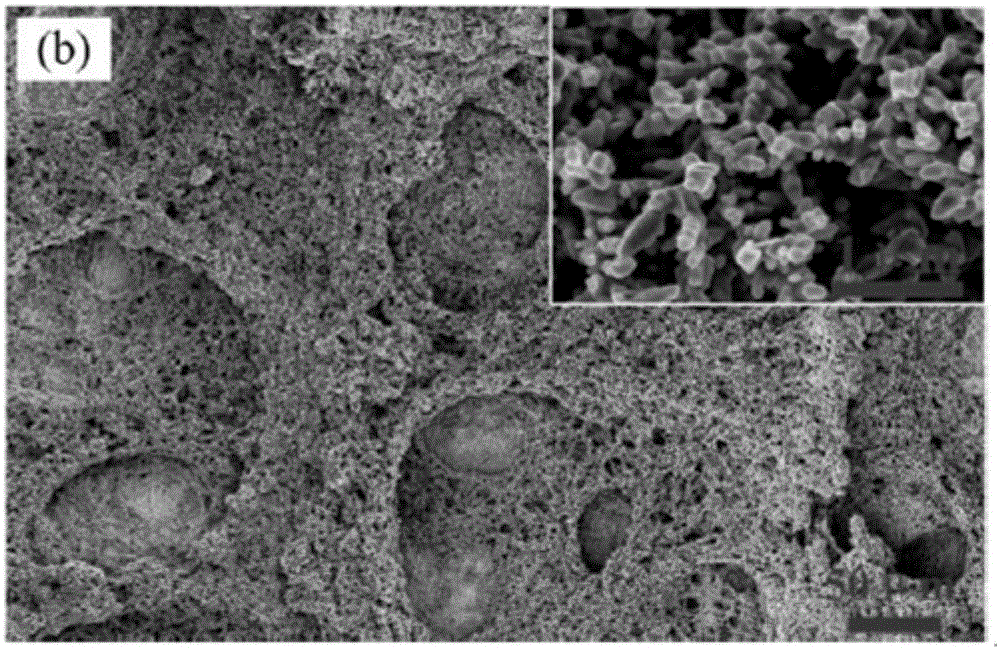

[0038] image 3 Middle, B samples: current density 1A / cm 2 , deposition time 15s;

[0039] (2) Select respectively figure 2 and image 3 Samples A and B in the sample were placed on the ultra-depth-of-field microscope workbench, and the focal length was adjusted to obtain a clear magnified image. The pictures were taken and the image magnification was recorded. The diffusion process of liquid droplets on different samples is recorded on the depth-of-field microscope, the recording time is 10s, the video sampling frequency is 28 frames / s, and the operating temperature is 21°C;

[0040] (3) Continuously capture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com