Porous material wettability measurement device and method based on infrared image processing

A technology of infrared image processing and porous materials, which is applied in the direction of measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve the problems of incomplete fit, quantitative evaluation of infiltration uniformity, and difficulty in accurate boundary of colorless liquid diffusion area Judgment and other problems to achieve the effect of solving incomplete measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

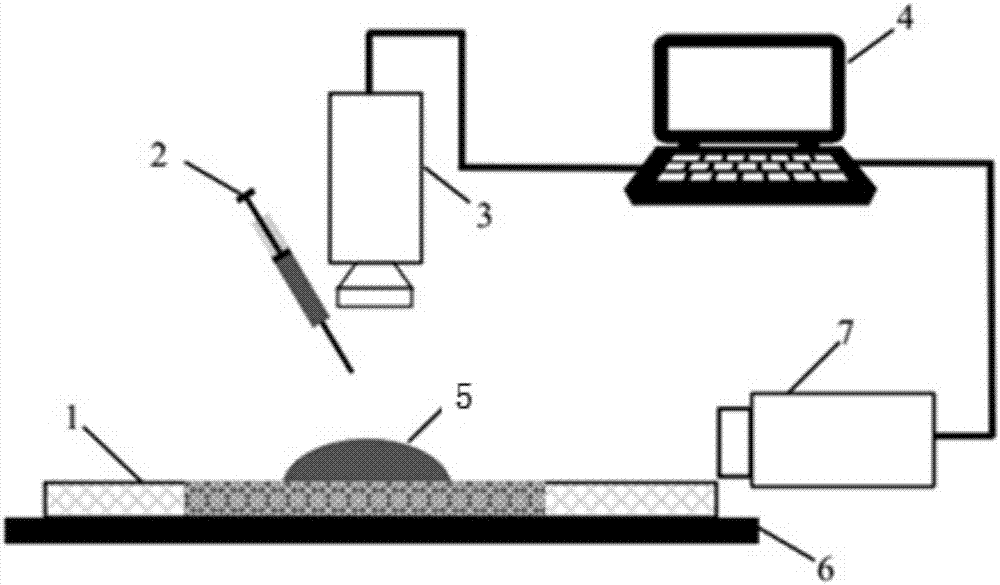

[0048] Such as figure 1 and figure 2 As shown, the porous material wettability measurement device based on infrared image processing includes a lifting platform 6 for placing a sample 1, an infrared thermal imager 3 placed above the lifting platform 6, and a high-speed camera 7 placed in front of the lifting platform 6 , the computer 4 connected to the infrared thermal imager 3 and the high-speed camera 7 data transmission lines, the injector 2 for injecting the liquid working medium 5 placed on one side of the lifting platform 6; the computer 4 is equipped with a device for processing infrared images The data processing software Research IR that comes with the infrared camera.

[0049] The injector 2 is arranged on one side of the lifting platform 6 through a movable support, and the movable support can move freely along any direction, so as to facilitate the necessary adjustment of the position and posture of the injector 2 .

Embodiment 2

[0051] In the method of measuring the wettability of porous materials using the measuring device, carbon fiber felt porous materials with two different structural parameters, A and B, are selected as the porous materials to be tested. The size is 40mm×40mm, and their structural parameters are: A sample (See Figure 7 ): porosity 88.6%; B sample (see Figure 8 ): the porosity is 77.1%; the preparation mass fraction is 50% ethanol aqueous solution as liquid working fluid 5, comprises the steps:

[0052] (1) Place A sample on the lifting platform 6 and fix it;

[0053] (2) adjust the thermal imager 3 so that the A sample presents a clear infrared image in the software Research IR;

[0054] (3) Move the movable support so that the needle tip of the syringe 2 is 4 mm above the sample A, and the angle between the syringe 2 and the sample is about 30° to 40°;

[0055] (4) adjust the focal length of the high-speed camera 7 so that the needle point of the syringe 2 presents a clear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com