Optical fiber contact member part

A technology of optical fiber contact and contact piece, which is applied in the direction of optical components, light guides, optics, etc., can solve the problems affecting the transmission of optical signals, etc., and achieve the effect of convenient assembly and good neutrality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

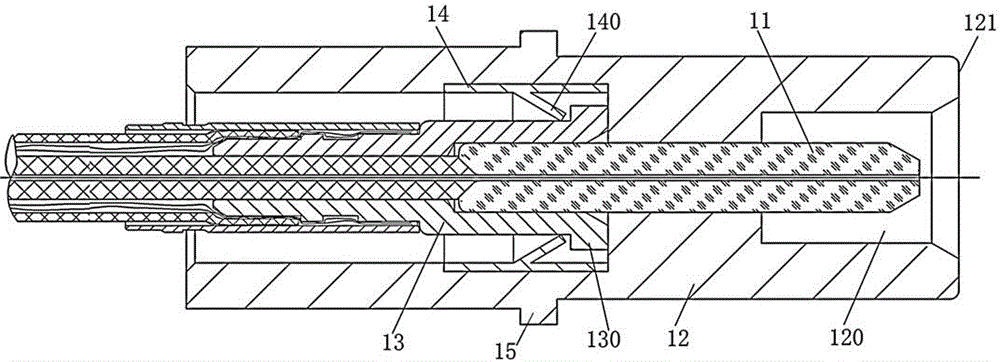

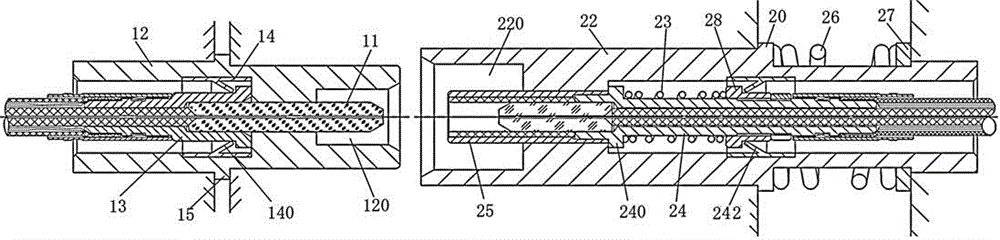

[0018] Embodiment 1 of the fiber optic contact part of the present invention: Since the fiber optic contact is used in conjunction with an adapted fiber optic contact part, for the convenience of description and understanding, the following describes the fiber optic contact part of the present invention and The contact parts that are compatible with the optical fiber contact parts of the present invention are described separately, and the process of plugging and using the two is described. In order to facilitate the distinction, the fiber optic contact parts of the present invention are named as female end contact parts below. , and the contact part suitable for the contact part of the present invention is named as the male end contact part:

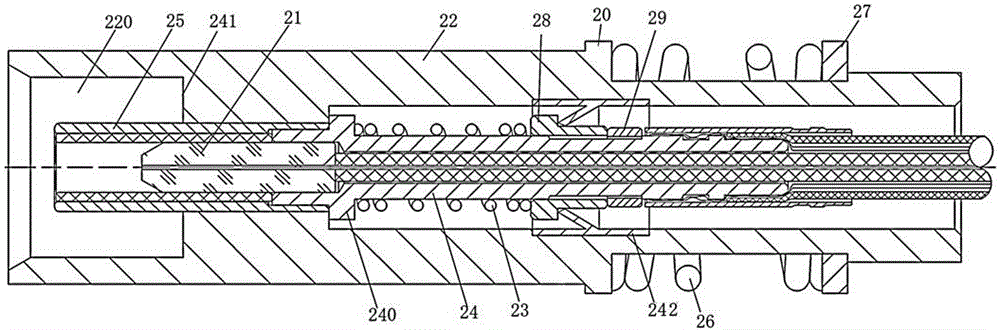

[0019] The structure of the receptacle contact part of the present invention is as follows figure 1As shown, it includes the female end contact body and the female end positioning shell arranged outside the female end contact body. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com