Method for obtaining quenching process heat transfer coefficient of aluminum alloy component under three-dimensional heat transfer condition based on finite element method

A technology of aluminum alloy components and three-dimensional heat transfer, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as inaccurate heat transfer coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

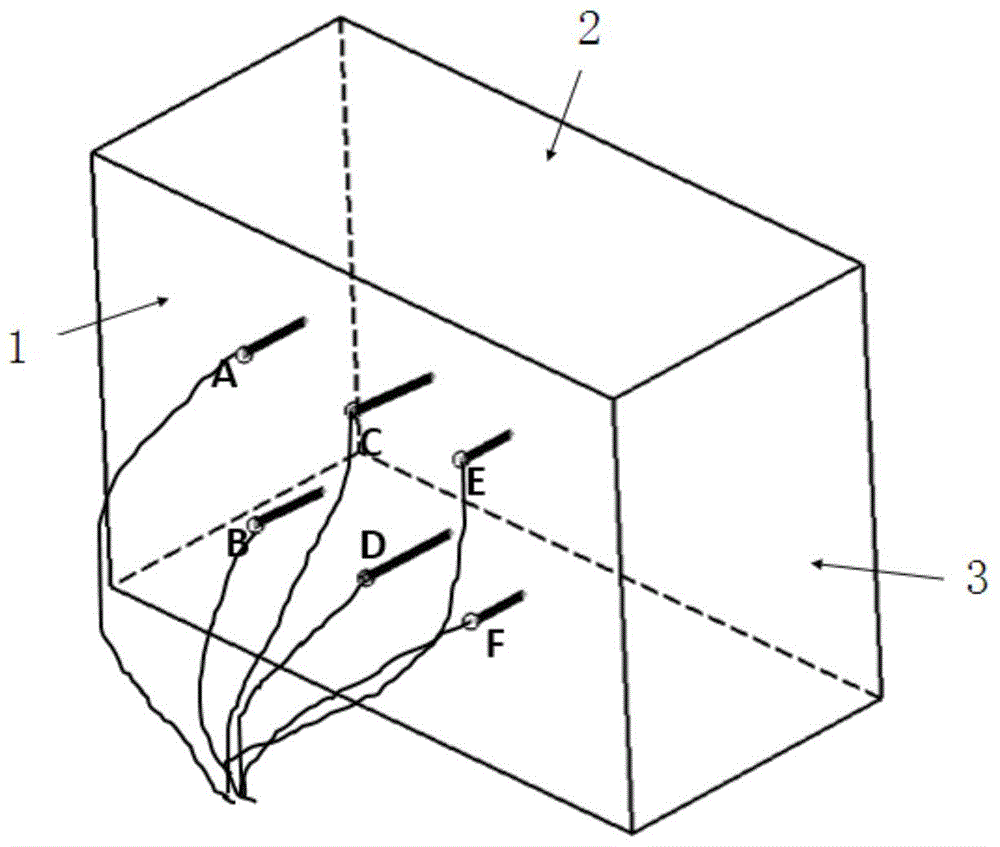

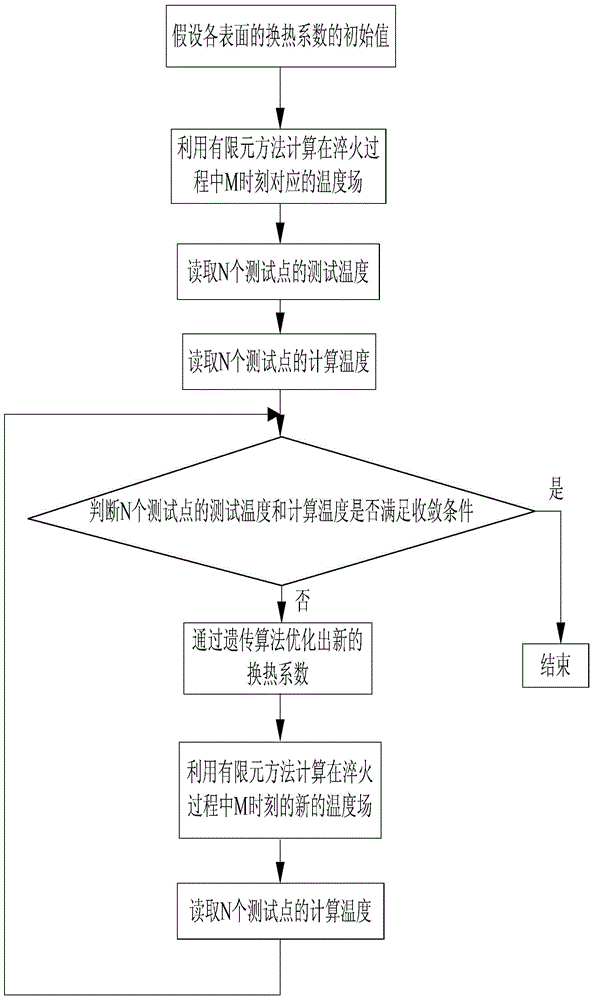

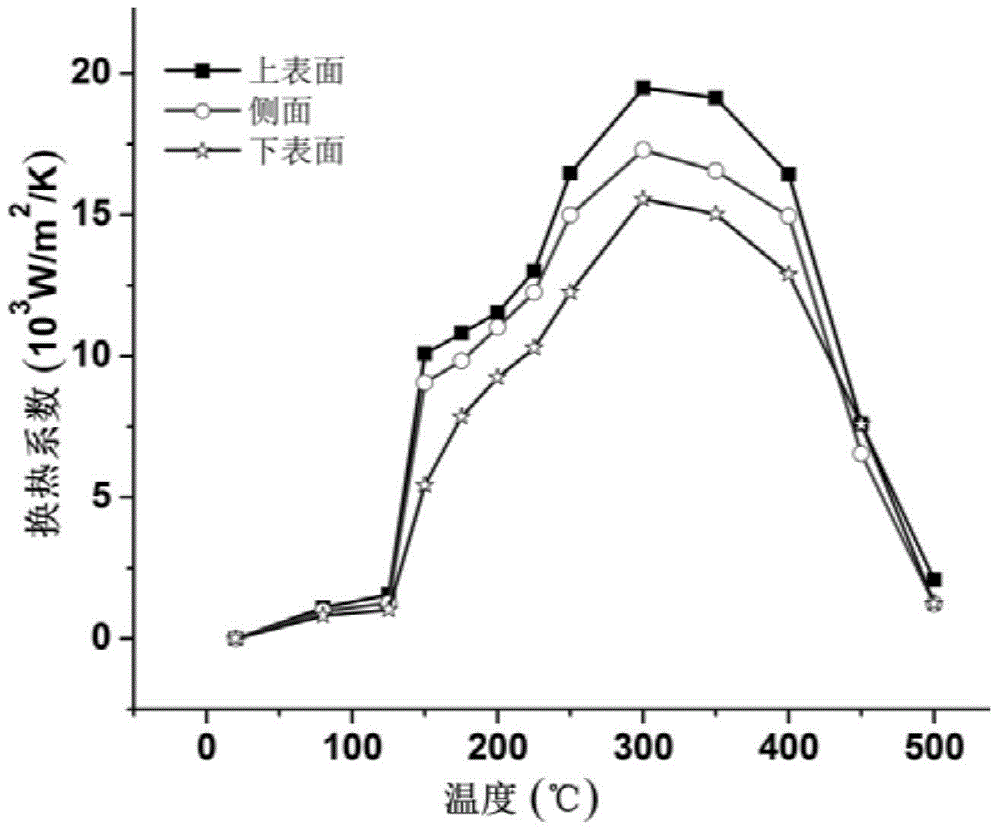

[0037] Specific implementation mode one: refer to figure 1 and figure 2 Specifically explain this embodiment, the method for obtaining the heat transfer coefficient of an aluminum alloy member during the quenching process under the three-dimensional heat transfer condition based on the finite element method described in this embodiment, the method includes the following steps:

[0038] Step 1: Embed N thermocouples evenly on the upper surface of the aluminum alloy member, that is, N test points, and the N output terminals of the N thermocouples are respectively connected to the N input terminals of the computer data acquisition system, and the aluminum alloy member is placed on the After heating to 450°C-550°C in the heating furnace and keeping the heat evenly, transfer it to the medium for quenching;

[0039] Step 2: Establish the three-dimensional heat conduction differential equation in the Cartesian coordinate system, and give the boundary conditions and initial conditio...

specific Embodiment approach 2

[0060] Specific embodiment 2: This embodiment is to further explain the method for obtaining the heat transfer coefficient of the aluminum alloy component quenching process under the three-dimensional heat transfer condition based on the finite element method described in the specific embodiment 1. In this embodiment, step 1 In the process, the transfer time of the aluminum alloy components from the furnace to the medium is less than 2s.

specific Embodiment approach 3

[0061] Specific embodiment 3: This embodiment is to further explain the method for obtaining the heat transfer coefficient of the aluminum alloy component quenching process under the three-dimensional heat transfer condition based on the finite element method described in the specific embodiment 1. In this embodiment, step 1 Among them, the medium is water or PAG organic solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com