MELF (Metal Electrode Leadless Face) component positioning and detecting method based on match template

A technology of template matching and detection methods, applied in computer parts, character and pattern recognition, image data processing, etc., can solve the problems of slow execution speed, large amount of calculation, slow component positioning and detection speed, etc., to reduce the search position , the effect of improving computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

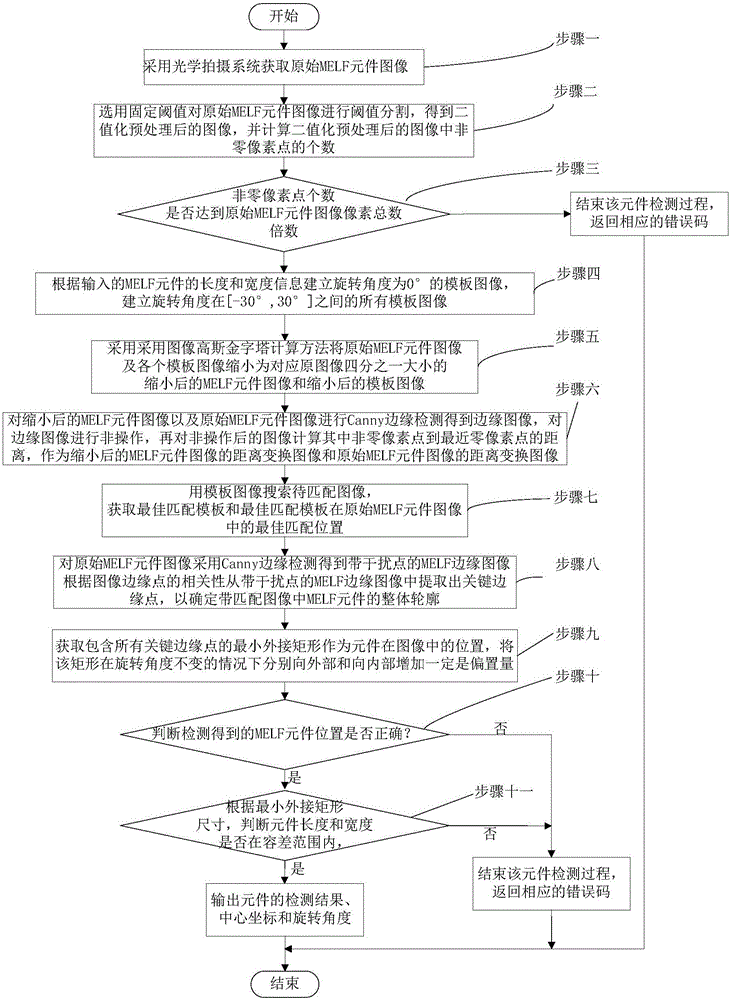

[0035] A kind of MELF element localization and detection method based on template matching of the present embodiment, such as figure 1 As shown, the MELF element positioning and detection method is realized through the following steps:

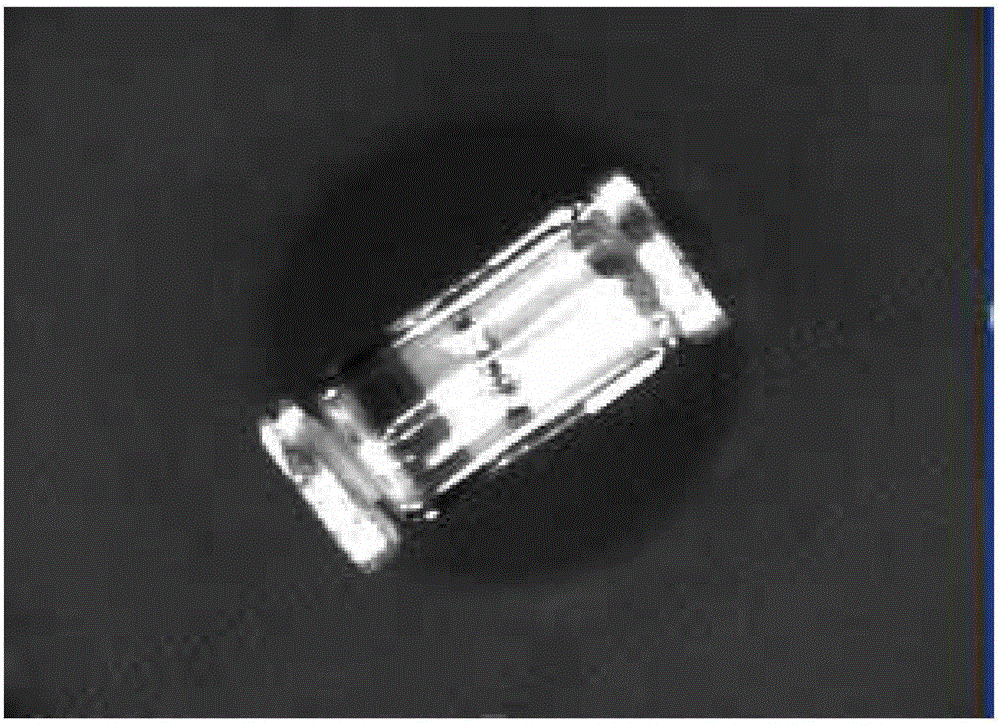

[0036] Step 1. Obtain the original MELF component image of the MELF component by using an optical shooting system;

[0037]Step 2, select a fixed threshold to carry out threshold segmentation on the original MELF component image obtained in step 1, obtain the image after binarization preprocessing, and calculate the number of non-zero pixels in the image after binarization preprocessing;

[0038] Step 3, judging whether the number of non-zero pixel points obtained in step 2 reaches the corresponding multiple of the total number of pixels in the original MELF component image, if not, then end the MELF component detection process, and return a corresponding error code; if so, continue to perform step 4;

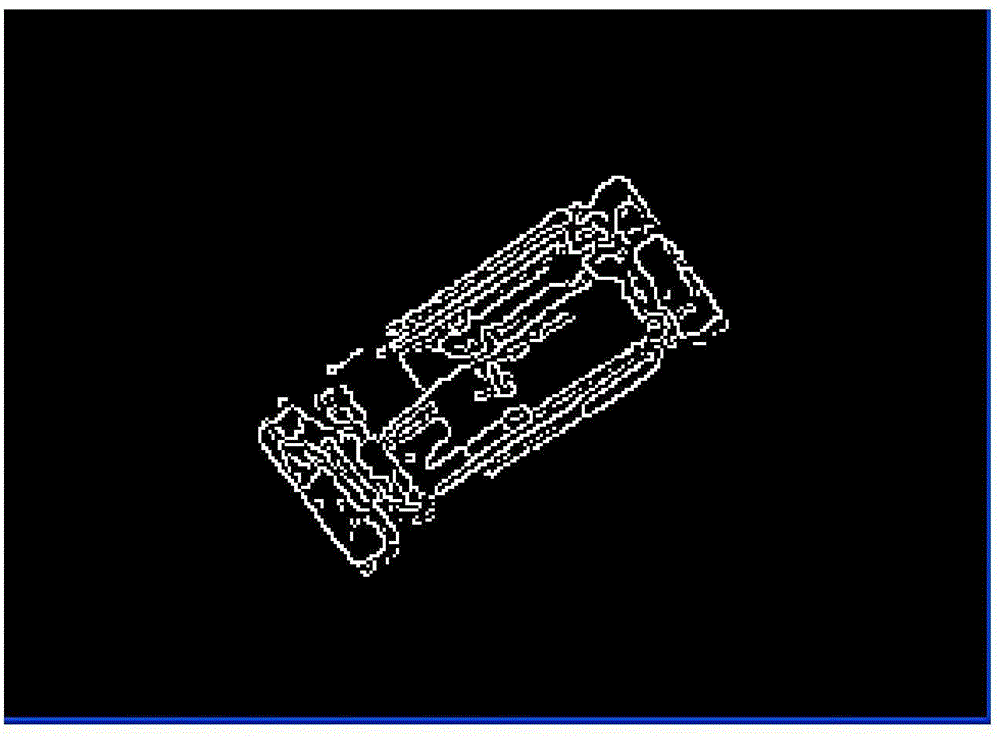

[0039] Step 4: Establish a template ima...

specific Embodiment approach 2

[0047] Different from Embodiment 1, in the MELF component positioning and detection method based on template matching of the present embodiment, the template image with a rotation angle of 0° is established according to the length and width information of the input MELF component described in step 4, and the rotation angle is 0 °. The template image with an angle of 0° is rotated with a step size of 1 degree, and the process of obtaining all template images with a rotation angle between [-30°, 30°] is,

[0048] Step 41, according to the length and width information of the input MELF element, obtain the template information with a rotation angle of 0°, and establish a template image with a rotation angle of 0°; wherein, the length of the MELF element corresponds to the width of the template image with a rotation angle of 0°, The width of the MELF element corresponds to the height of the template image whose rotation angle is 0°;

[0049] Step 42: Rotate the template image with ...

specific Embodiment approach 3

[0050] Different from the specific embodiment 1 or 2, the specific calculation process of the image Gaussian pyramid calculation method described in step 5 of the MELF element positioning and detection method based on template matching in this embodiment is as follows:

[0051] Step 51. Suppose that the pyramid image to be obtained includes an i+1 layer image, and each layer image in the pyramid image is obtained from the same original MELF component image, and the levels of the pyramid image are numbered from bottom to top, and the higher the level The smaller the image, the highest i+1th layer represents the highest level of the pyramid image, G i Represents the pyramid image of level i; then G i with a Gaussian kernel 1 16 1 4 6 4 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com