Processing device for rubber sheath in mining cables

A technology for processing devices and cables, applied in the directions of marking conductors/cables, cable/conductor manufacturing, circuits, etc., can solve problems such as the inability of rubber-sheathed cables to be realized, and achieve the effects of low cost of use, clear and complete printing, and clear printing content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

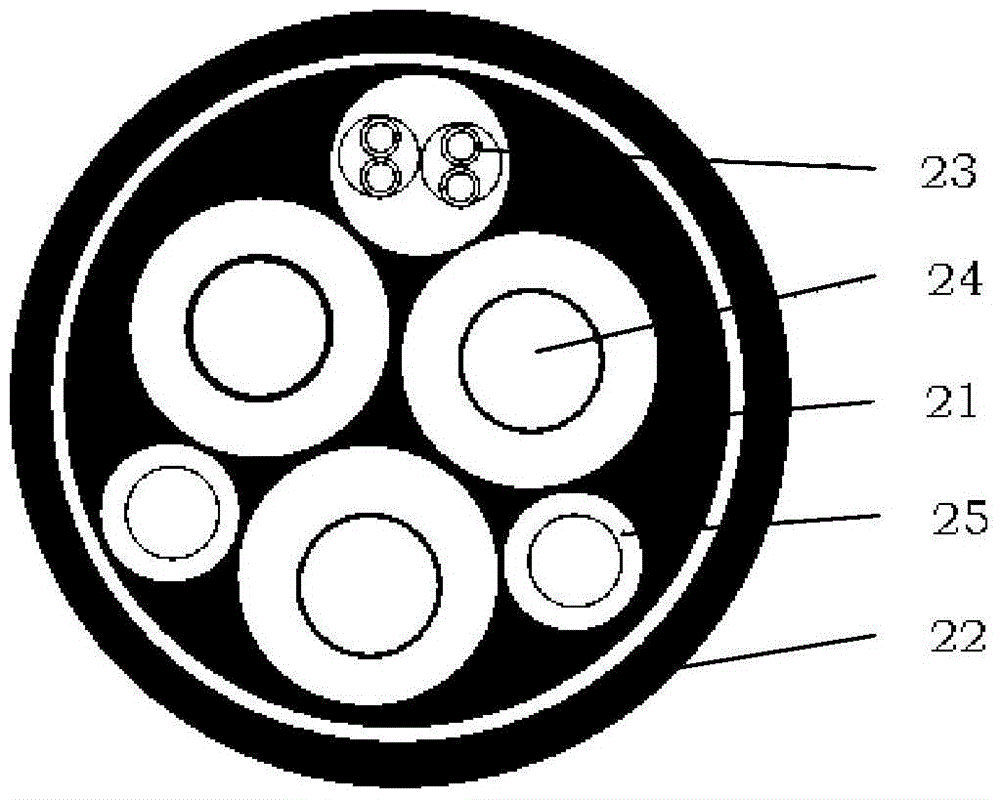

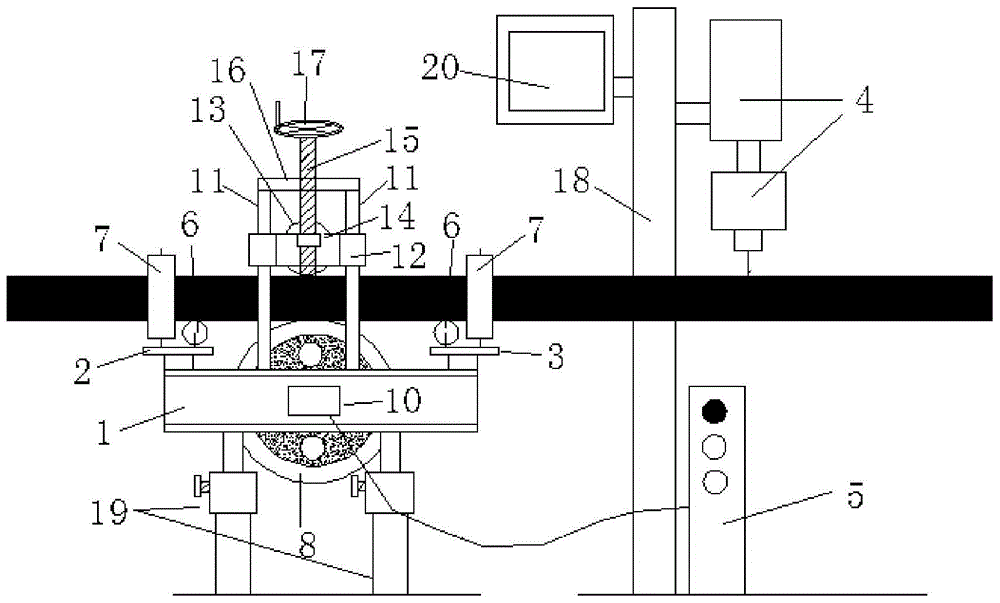

[0018] Embodiment: A kind of processing device of rubber sheath in mine cable, described mine cable comprises cable core 21 and the sheath layer 22 that is positioned at the outer surface of cable core 21, and described cable core 21 is made of control wire core 23, three A power wire core 24 and a ground wire core 25 are stranded; it is characterized in that: the sheath layer 22 is a chlorinated polyethylene rubber material, and the sheath layer 22 of the mining cable forms a white color on the surface through a printing device. Concave pattern;

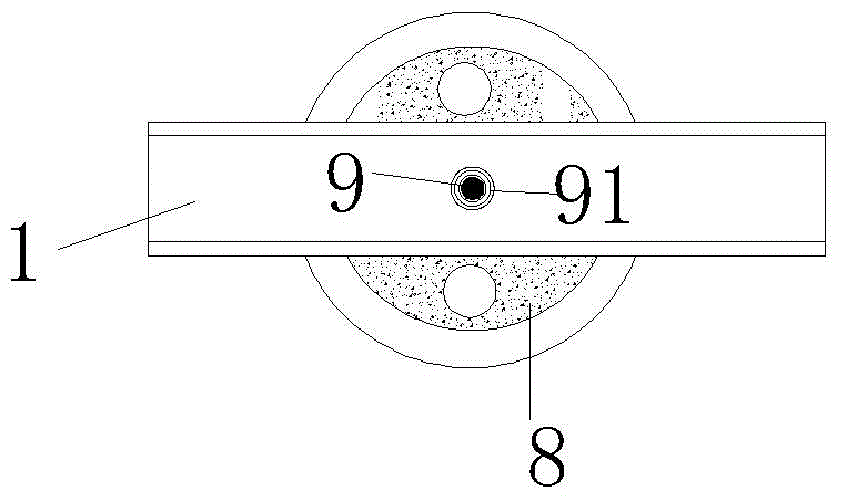

[0019] The printing device includes a side base plate 1, a front support plate 2, a rear support plate 3, a laser generator 4, a control panel 20 and a host 5, and the front end and rear end of the left side of the side base plate 1 are respectively fixed with a front support plate 2 , rear support plate 3, before support plate 2, rear support plate 3 upper surfaces all install pulley 6,2 positioning wheels 7 that are respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com