Frequency multiplication chopping control circuit for double-winding high-speed brushless DC motor and winding switching control method

A brushed DC motor and control circuit technology, applied in the direction of DC motor speed/torque control, control system, electrical components, etc., can solve the problem of complex off-line process, narrow speed regulation range, increase of system volume and weight by inverter circuit, and loss and other problems, to achieve the effect of reducing the volume and weight of the system and reducing the volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

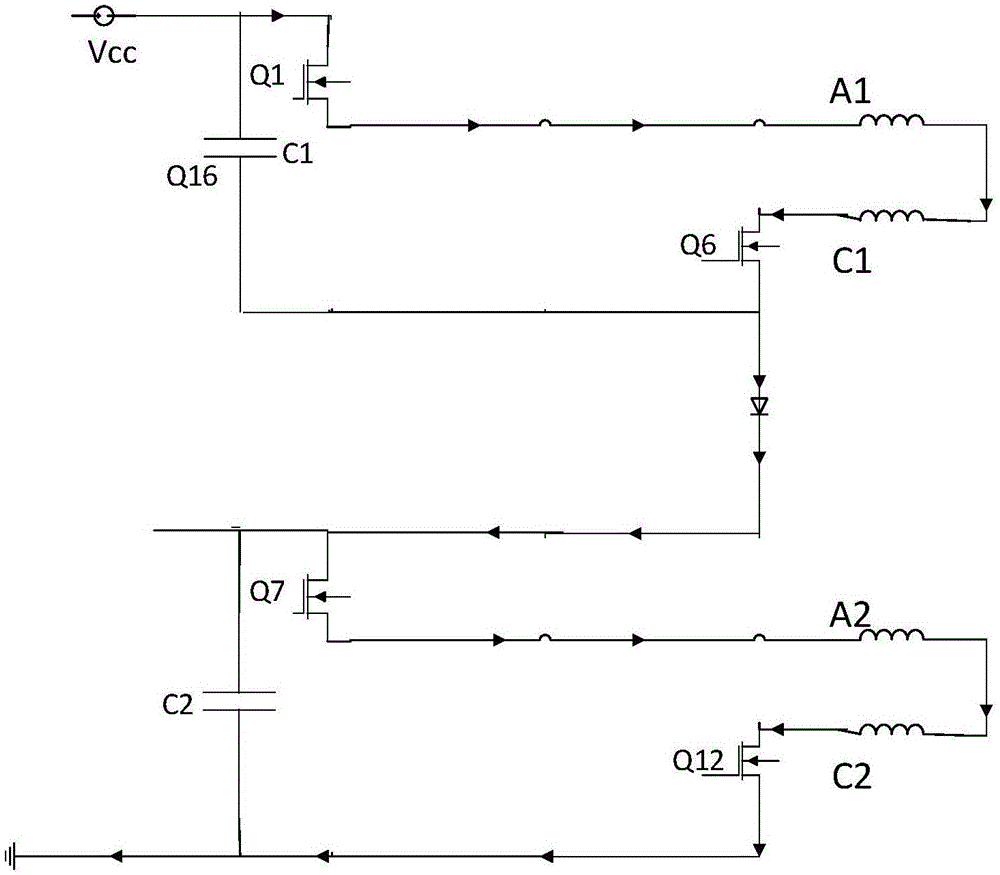

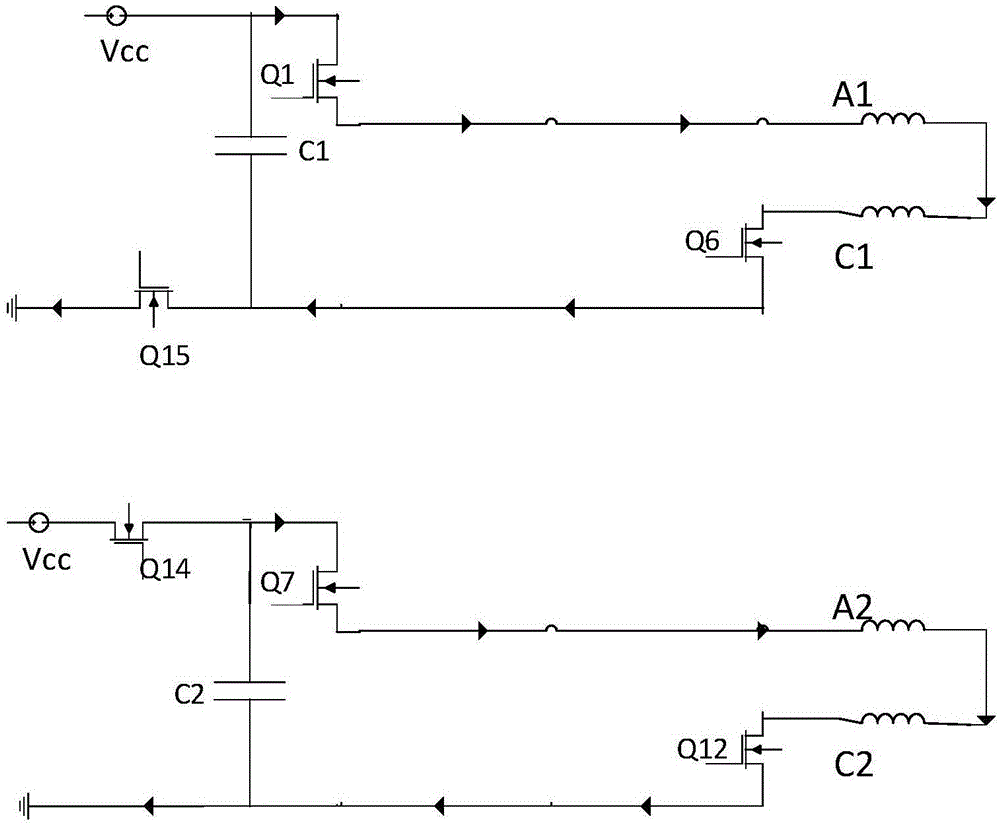

[0025] The invention utilizes two sets of inverters to respectively control two separate sets of three-phase windings, and realizes the series-parallel connection of the motor windings by adding a switching tube. In the starting stage, the motor can be connected in series to obtain a larger starting torque. After the start is completed, it can be converted into a parallel connection to obtain a larger speed range.

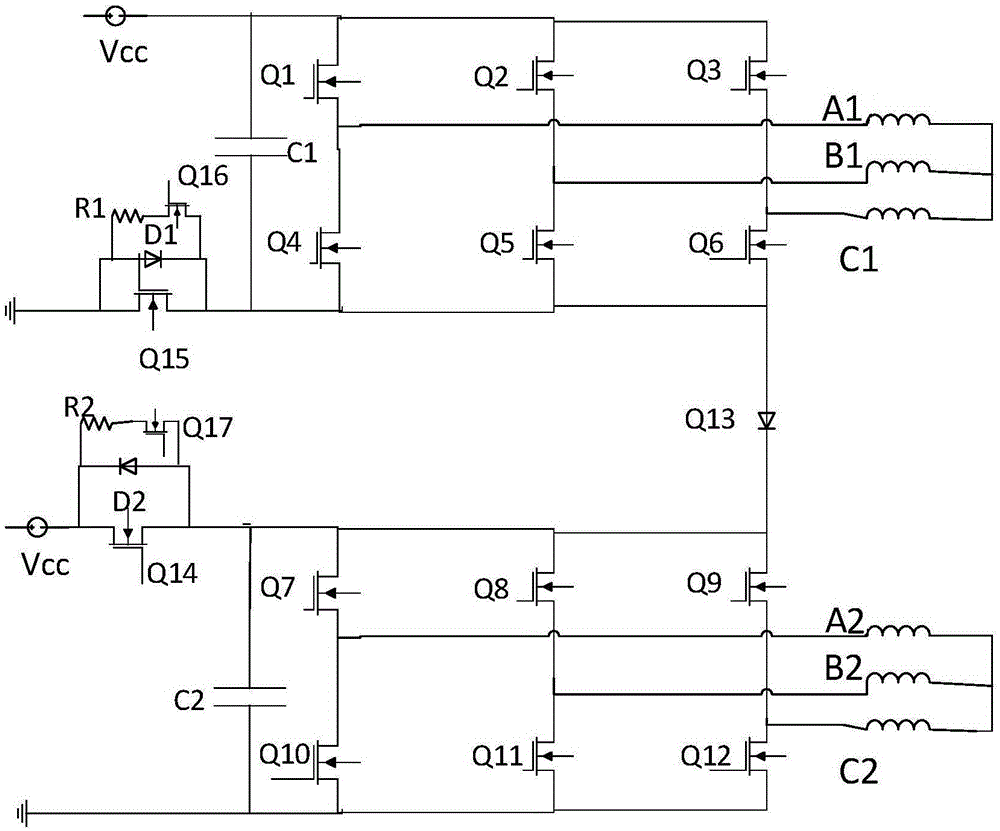

[0026] Such as figure 1 As shown, a dual-winding three-phase motor winding switching topology circuit and a winding switching control method are provided. The present invention includes: two separate inverter circuits (Q1-Q6, Q7-Q12) and two separate Y-connected windings (A1, B1, C1; A2, B2, C2), two bus capacitors (C1 , C2), two switch tubes (Q14, Q15), two charging circuit resistors (R1, R2) and switch tubes (Q16, Q17) antiparallel diodes D1, D2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com