Gyration type hydraulic operated valve

A rotary valve technology, applied to valve details, valve devices, engine components, etc., can solve the problems of large overall height, small power and torque, burning motor, etc., and achieve high degree of automation control, large starting torque, Run Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

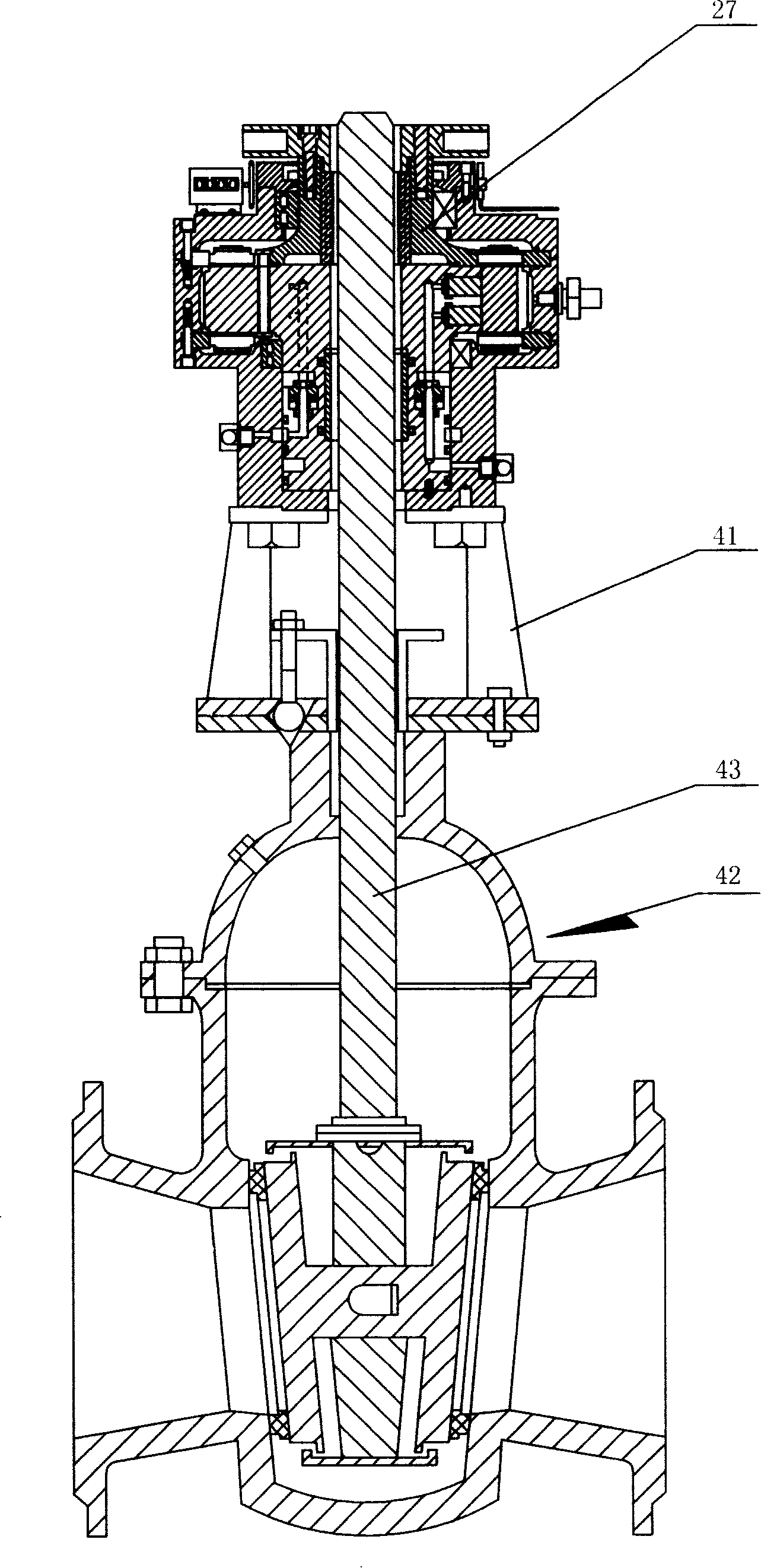

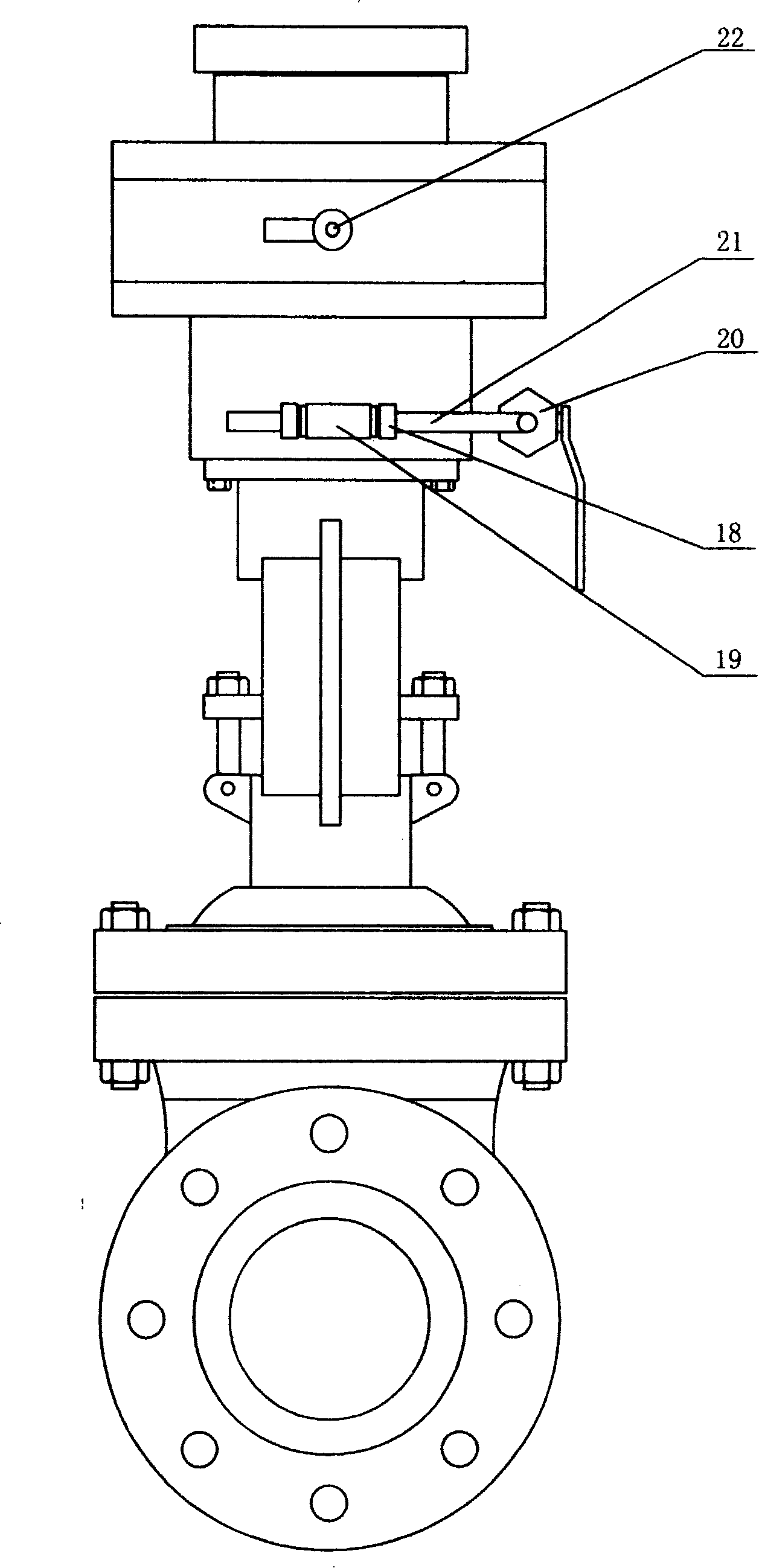

[0020] The rotary hydraulic valve includes a hydraulic motor, a valve 42 and a connecting bracket 41. The valve 42 is suitable for various known general purpose valves.

[0021] Hydraulic motor, including housing 1, front end cover 37, rear end cover 14, hollow output shaft 28, front flange 39, tapered roller bearing 34, tapered roller bearing 17, inner curved guide rail 4, beam 19, roller 21, Hollow plunger cylinder 2, a plurality of plungers 18, oil distribution sleeve 11, oil distribution plate 16, compression sleeve 15 and manual hinge plate 30 etc. A sealing member 3 and an inner curved guide rail 4 are respectively arranged in the track grooves at the upper and lower ends of the housing 1 . A plurality of plungers 18 are installed in the plunger holes on the hollow plunger cylinder body 2 respectively, and a crossbeam 19 is installed on the outer end of the plunger, and rollers 21 are respectively installed on the two ends of the crossbeam 19, and are held by the flat p...

Embodiment 2

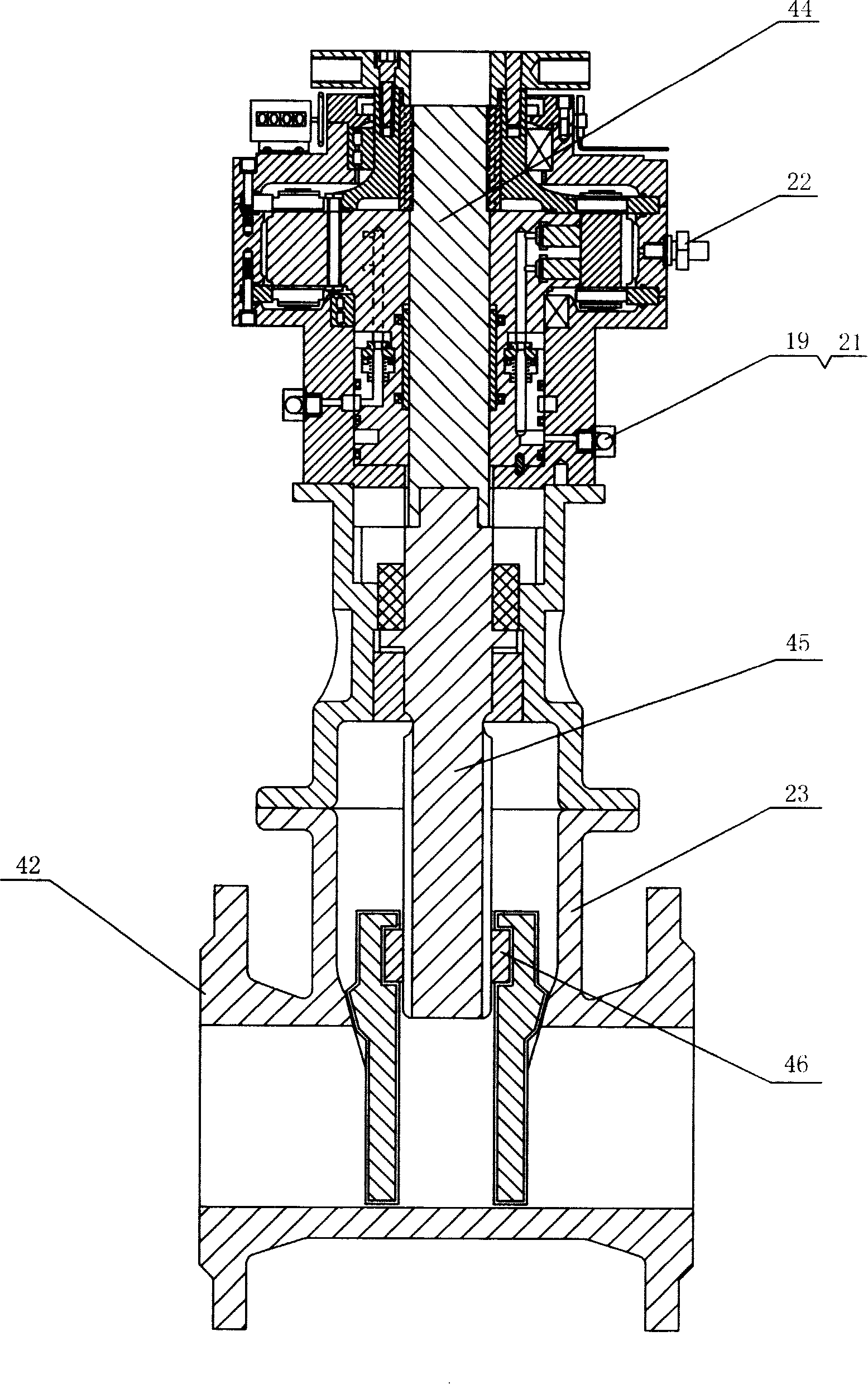

[0023] The second embodiment is basically the same as the first embodiment, except that the valve 42 is a dark rod valve structure, see image 3 , the valve stem does not move up and down. The valve stem 43 in the first embodiment is formed by connecting an upper solid valve stem 44 and a lower valve stem 45 , and the upper end of the upper solid valve stem 44 is connected with a key or a tooth in the inner hole of the hollow output shaft 28 . The driving nut 27 in the first embodiment is cancelled. The lower end of the lower valve rod 45 is connected with the nut 46 fixed on the valve plate with a T-shaped thread. Conforms to the connection method of the screw rod of the concealed rod valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com