Composite rotor system of wind motor

一种风力发动机、复合转子的技术,应用在风力发动机的控制、风力发动机、与风向一致的的风力发动机等方向,达到优异捕风效率、拓宽速度范围和地域范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the invention is described in further detail:

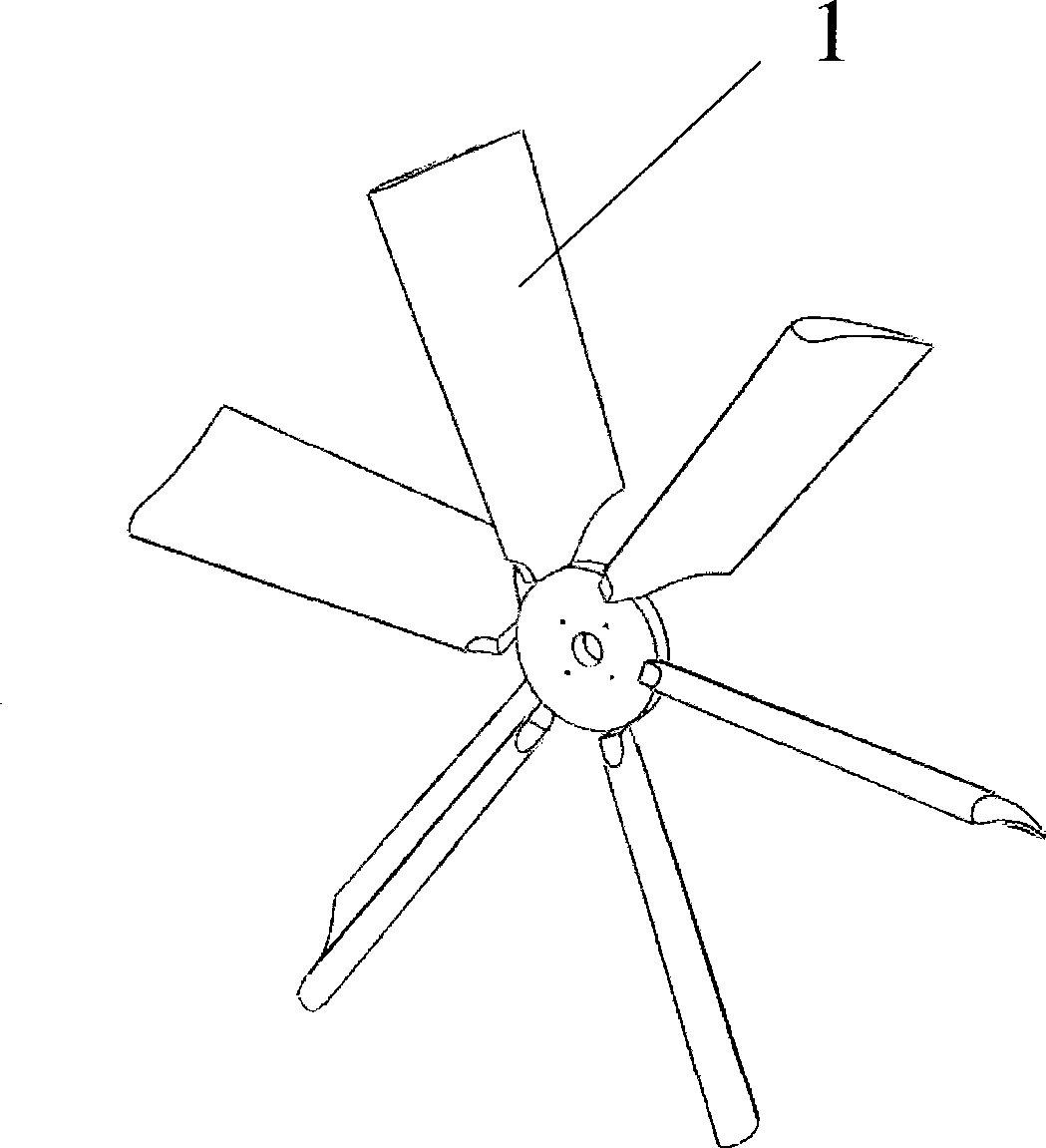

[0043] Such as figure 1 Shown is a preferred embodiment of a pilot rotor unit composed of 6 blades. Obviously, it has a large number of blades, a large blade area, and a large angle of attack, so the overall wind-catching ability is strong, and it is easy to capture when the wind speed is low. Wind energy, but after it obtains a certain rotation speed, the aerodynamic assistance it receives is also greatly increased, and the efficiency of wind energy utilization is greatly reduced. This feature belongs to common knowledge in the field of aerodynamics and wind energy technology, so this manual will not repeat it.

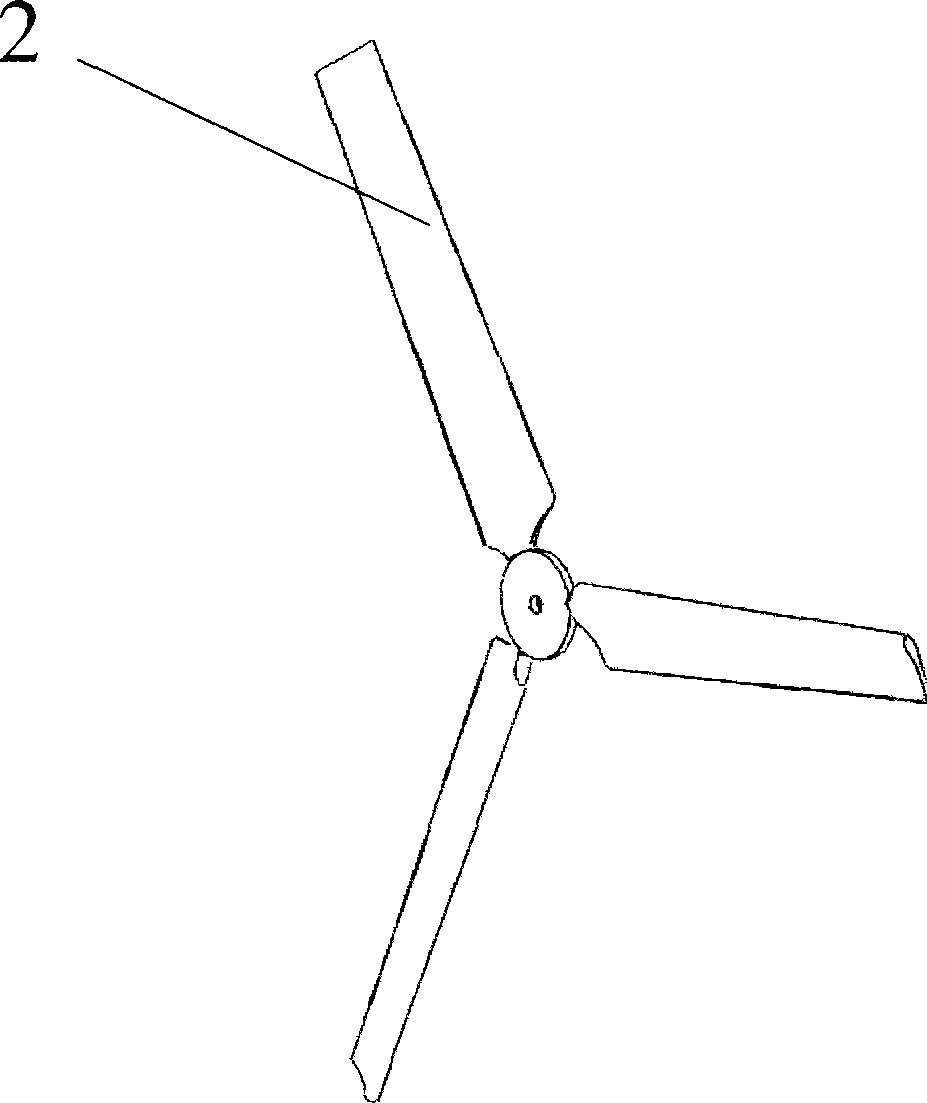

[0044] Such as figure 2 Shown is a preferred embodiment of the main rotor unit composed of 3 blades. Obviously, compared with the pilot rotor unit, it has fewer blades, smaller blade area, and smaller angle of attack, so the wind-catching ability at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com