Elevating dried food stir-frying machine

A stir-frying machine, lift-type technology, applied in the application, food processing, food science and other directions, can solve the problems of increased workload, inconvenience, tooth damage, etc., to achieve uniform stir-fry, simple equipment structure, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

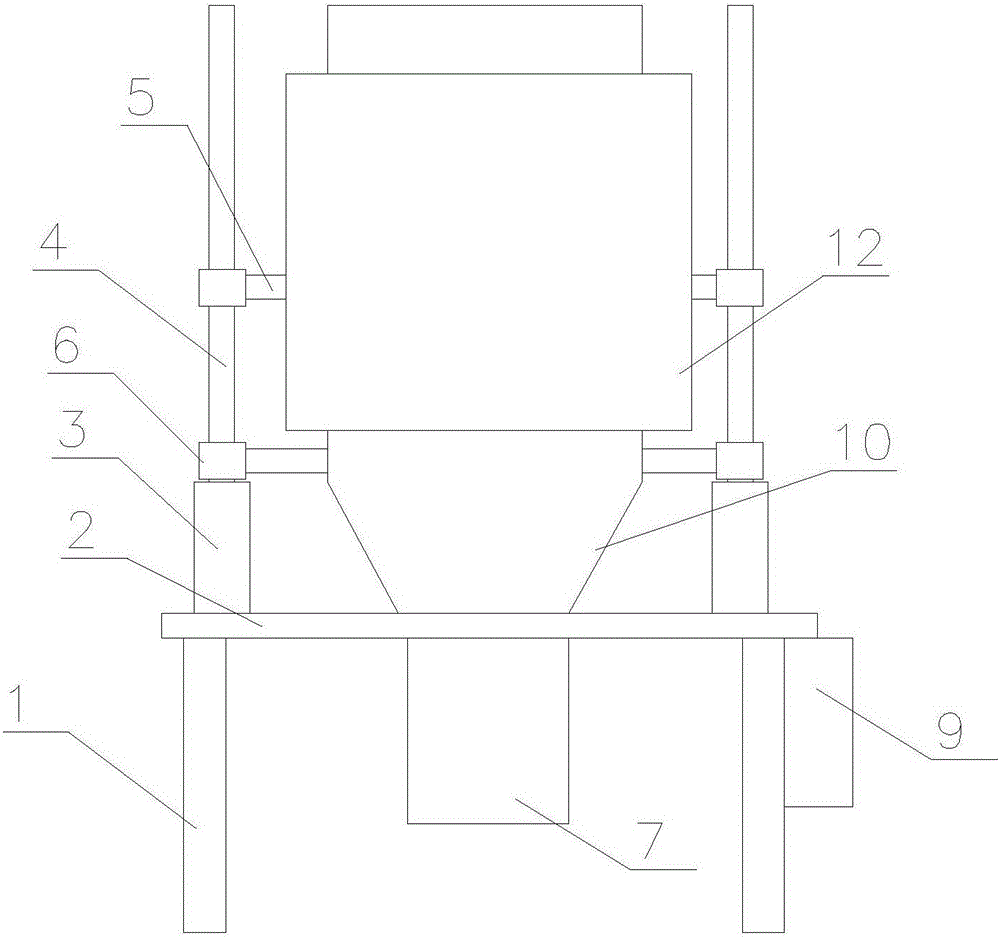

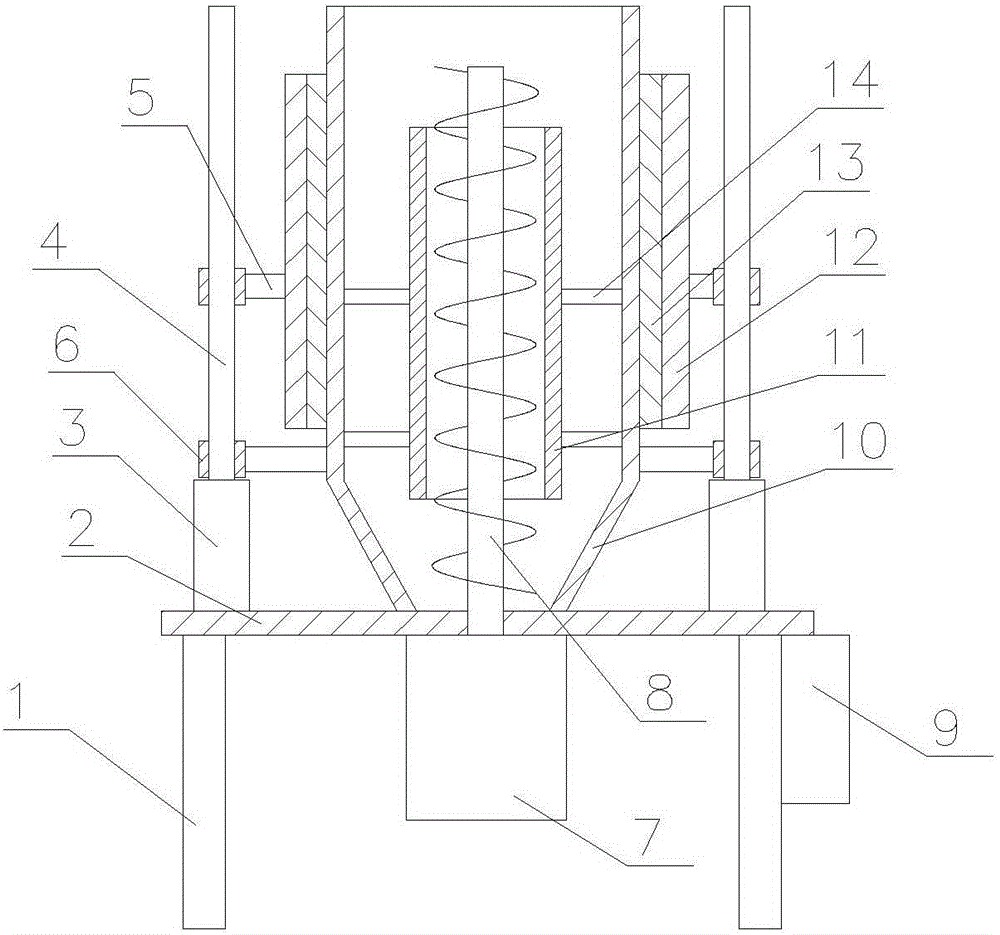

[0016] refer to figure 1 and figure 2 , a lifting type dry goods stir frying machine according to the present invention, comprising a lower leg 1, a working table 2, a limit block 3, a guide rod 4, a lifting handle 5, a sliding sleeve 6, a feeding motor 7, a screw rod 8, an electric Control box 9, main turning barrel 10, lifting barrel 11, heat preservation sleeve 12 and heating wire 13, the workbench 2 is circular, and the lower part of the workbench 2 is provided with four lower legs 1. The height of the workbench 2 is 100-300mm. An electric control box 9 is installed on the lower leg 1. A timer, a relay and a circuit switch are arranged in the electric control box 9. The circuit switch is respectively connected to the timer through wires. , relay connection, the edge of the workbench 2 is provided with 1-5 guide rods 4, the bottom of the guide rods 4 is provided with a limit block 3, and the bottom of the workbench 2 is fixed with a feeding motor 7 by bolts. A screw rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com