Mop head of water spraying mop and water spraying mop

A mop head and mop technology, applied in the direction of cleaning carpets, cleaning floors, cleaning equipment, etc., can solve the problems of affecting the service life and use effect, uneven force of mopping and washing, and low processing efficiency, so as to achieve the optimization of physical structure and the best effect Good, easy to operate and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

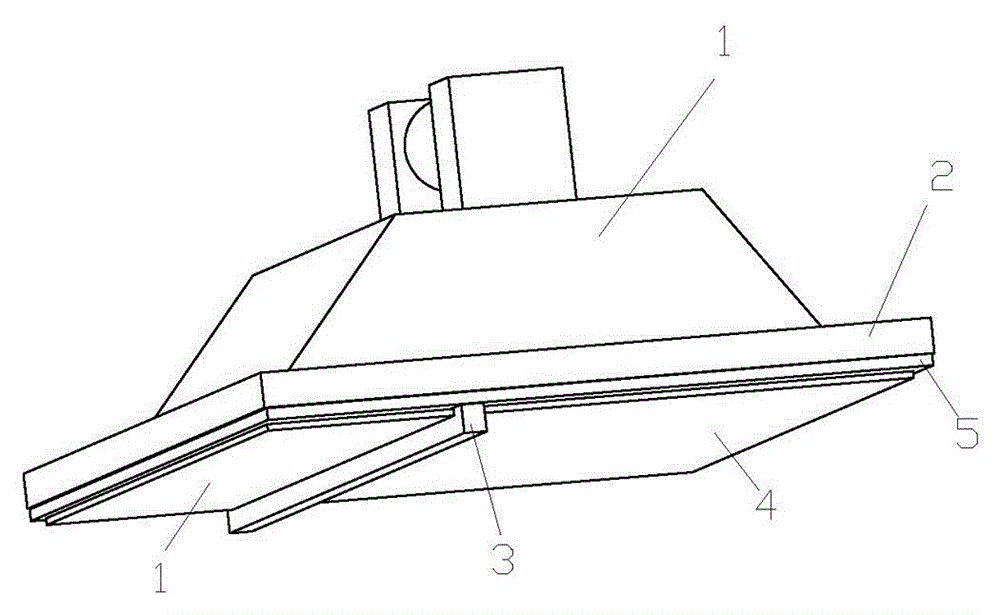

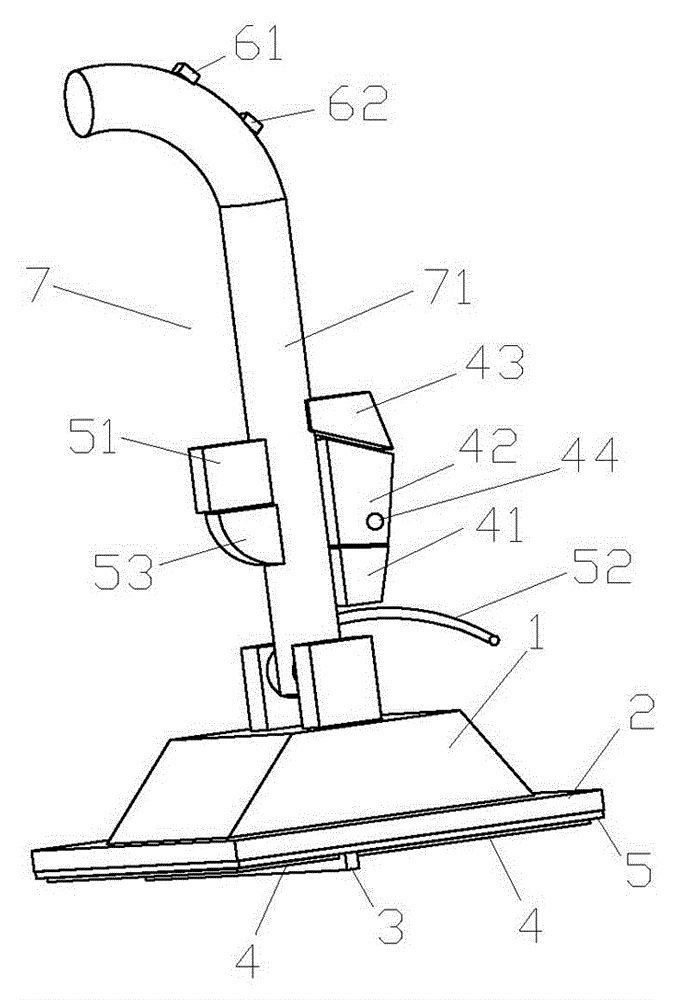

[0027] Example 1, such as figure 1 , 2 , 3, and 4, a mop head of a water spray mop includes a base 1 that can be connected to the handle body 7 of the water spray mop, and the back of the base 1 faces the base 1 and the handle body 7 One side of the connected position is used as the working part and is provided with a panel 2, and the side of the panel 2 facing away from the base 1 is provided with a supporting transition mopping scraper 3 and cooperates with the supporting transition mopping scraper 3 Mopping action layer 4 for mopping.

[0028] The mopping layer 4 is a non-woven fabric layer, and the mopping layer 4 is detachably connected to the panel 2 . The side of the panel 2 facing away from the base 1 is provided with a magic hook layer 5 for detachable connection with the mopping layer 4 . The supporting transition mopping scraping strip 3 is a flexible material scraping strip. The mopping layer 4 is provided in the area separated by the supporting transition...

Embodiment 2

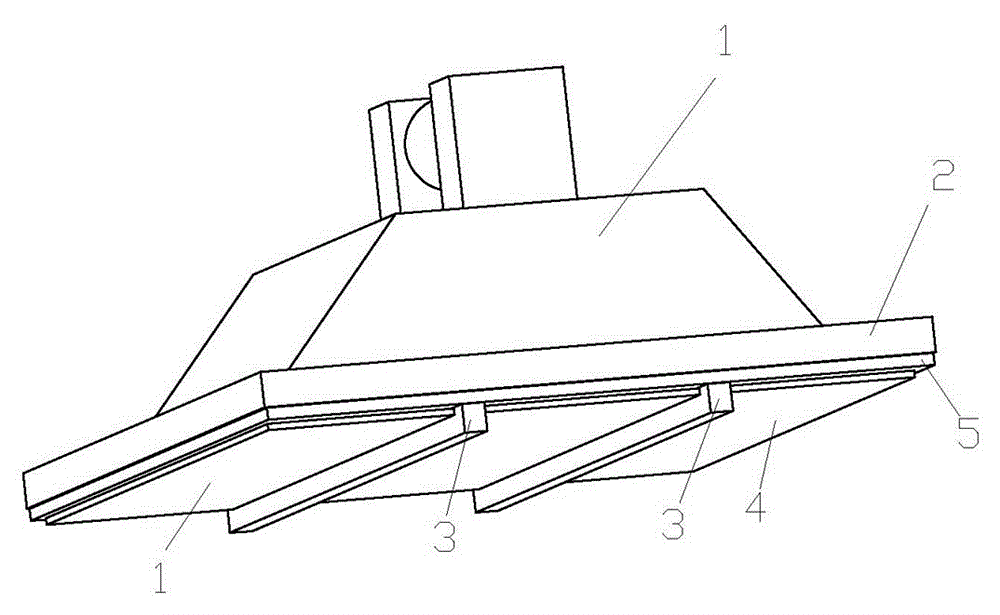

[0030] Example 2, such as Figure 5 As shown, the difference between it and Embodiment 1 lies in that the supporting transition mopping strip 3 extends in an arc shape on the side of the panel 2 facing away from the base 1 .

Embodiment 3

[0031] Example 3, such as Figure 6 As shown, the difference of the remaining embodiment 1 is that: the supporting transition mopping strip 3 surrounds the area on the side of the panel 2 facing away from the base 1 to form a circle shape or a rectangular shape. Since it is a whole strip structure, A structure in which a plurality of supporting transition mop strips 3 are nested on the panel can be adopted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com