Orthodontic bracket and manufacturing method thereof

A technology for orthodontic brackets and manufacturing methods, applied in the field of orthodontics, can solve the problems of high price, complex structure, and high cost, and achieve the effects of convenient manufacturing, increased height, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

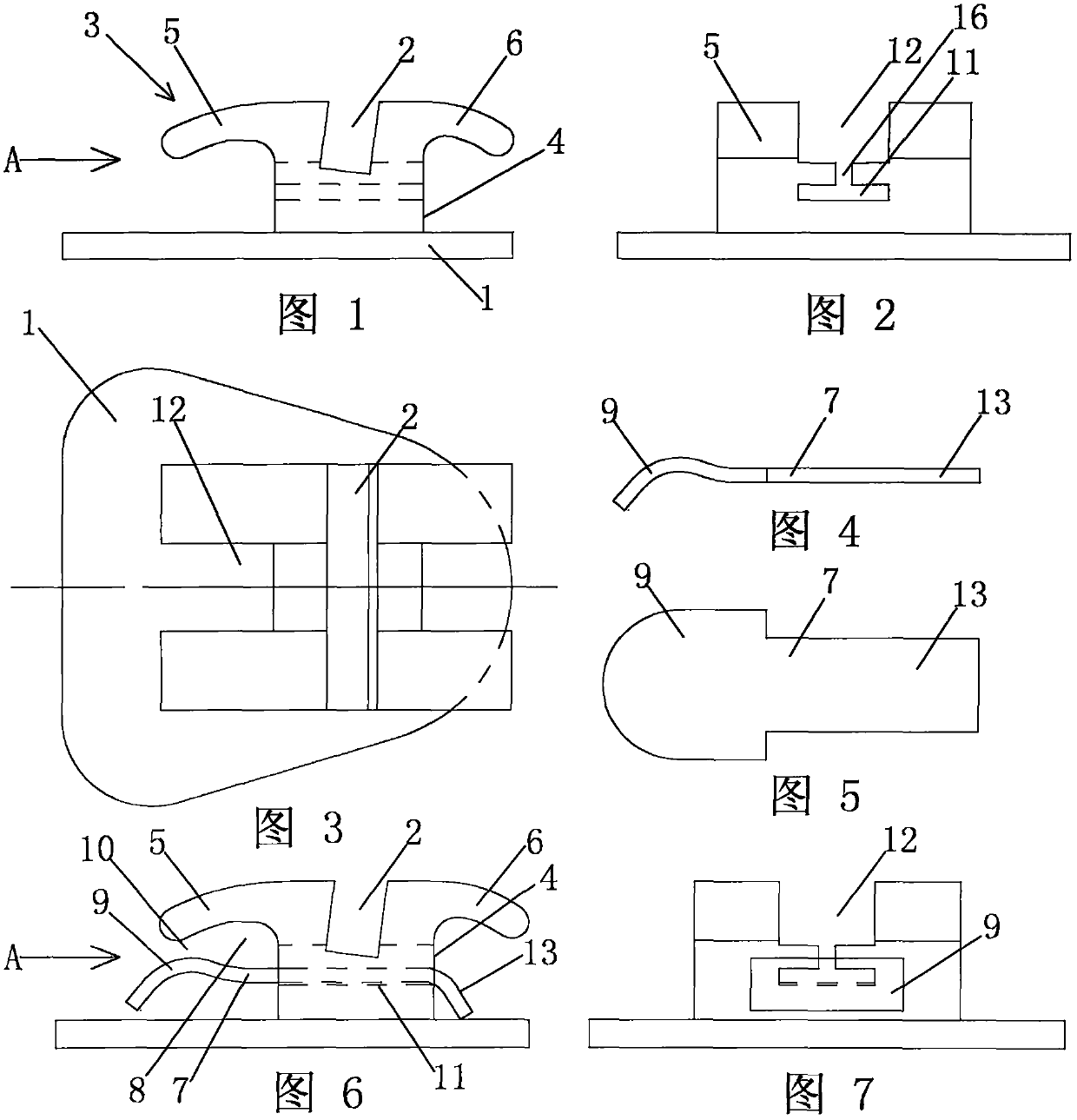

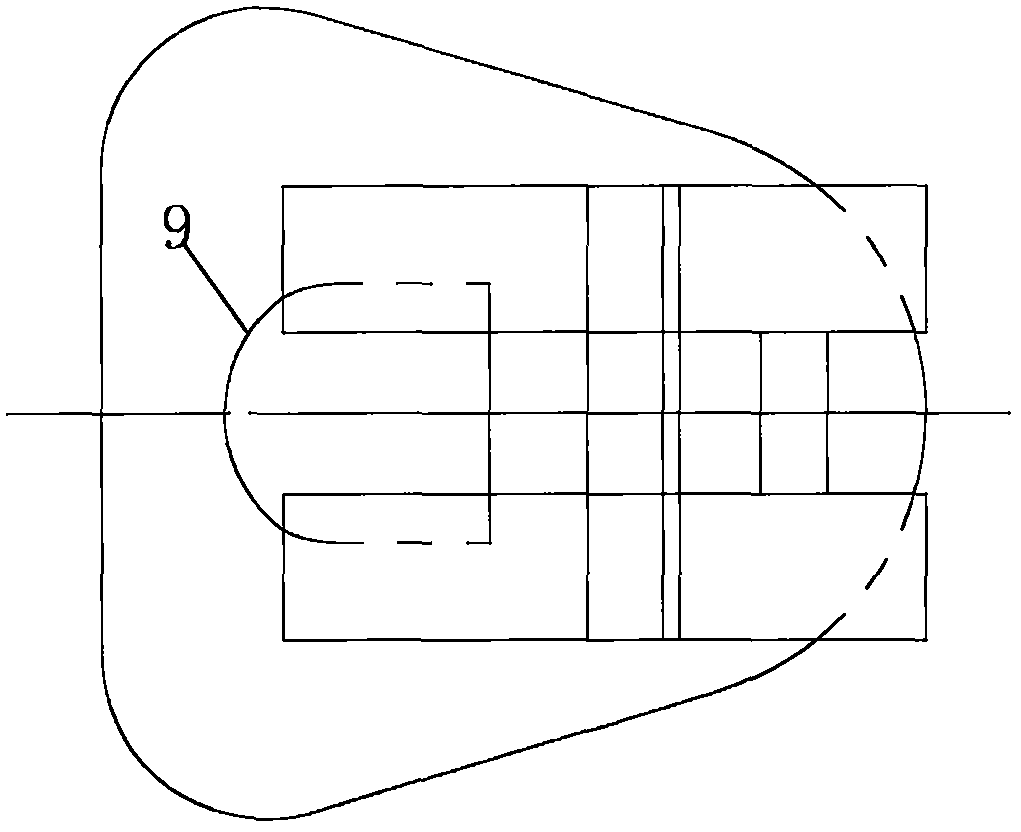

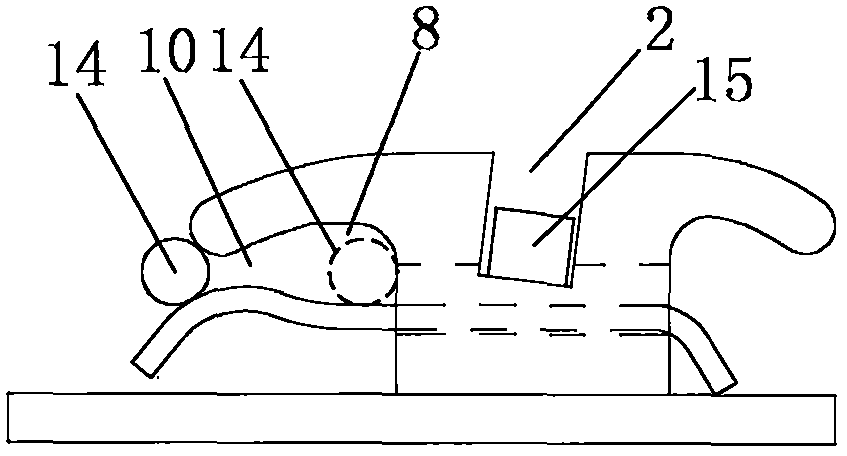

[0041] Embodiment: the orthodontic bracket of the present embodiment is a double-wing hook bracket, such as Figure 1-9 As shown, the bracket 3 includes a bracket body 4 with a mesh bottom 1 and a main archwire groove 2, and a bracket opening 12 is arranged at the intersection of the main archwire groove 2, and the main archwire groove in the bracket body 4 2 Ligating wings 5 and 6 are arranged on both sides, and the bracket opening 12 is intersected with the main archwire groove 2. The bracket opening 12 and the main archwire groove 2 divide the ligation wings 5 and 6 into four separate pieces, An elastic reed 7 is provided under the ligature wing 5 on one side, and an auxiliary archwire groove 8 is formed between the reed 7 and the ligature wing 5 , and the reed head 9 is connected to the ligature wing 3 A notch 10 is left between the edges for the secondary arch wire to slide into.

[0042] Specifically, the size of the notch 10 of the auxiliary archwire groove 8 is sm...

Embodiment 2

[0046] Embodiment 2: The principle of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figures 11-17 As shown, the bracket in this embodiment is a single-wing hook bracket. Because the tooth width of the lingual side is smaller than that of the labial side, it is better to use a single-wing double groove when correcting the lingual side. The head 9 of the reed 7 is bent only once, ie in the direction away from its adjacent ligating wing 5 . Note: One bend and multiple bends are related to the torque angle of the bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com