Feeding device with swing arms and guide rails matched and for bag making machine

A feeding device and bag making machine technology, applied in container manufacturing machinery, rigid/semi-rigid container manufacturing, packaging, etc., can solve the problems of manual installation of raw materials, high production costs, complex structure, etc. Material machinery, simplified structure, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

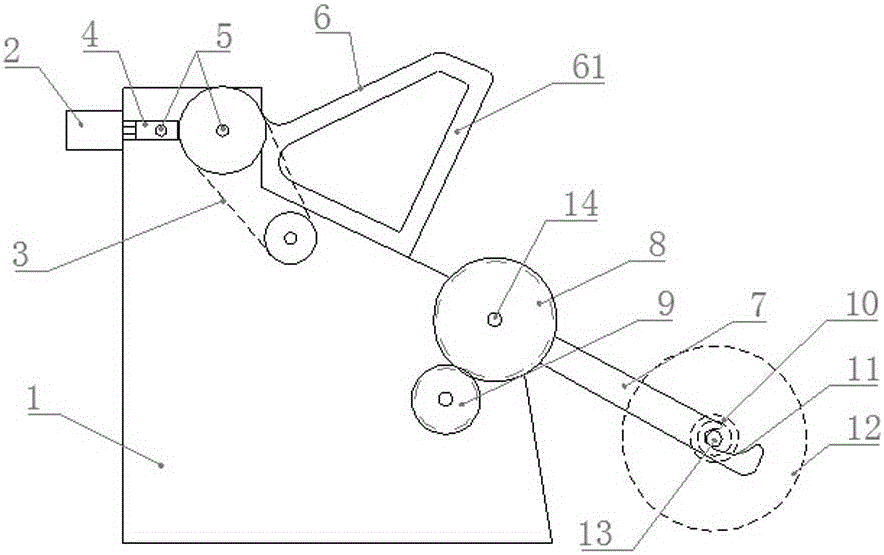

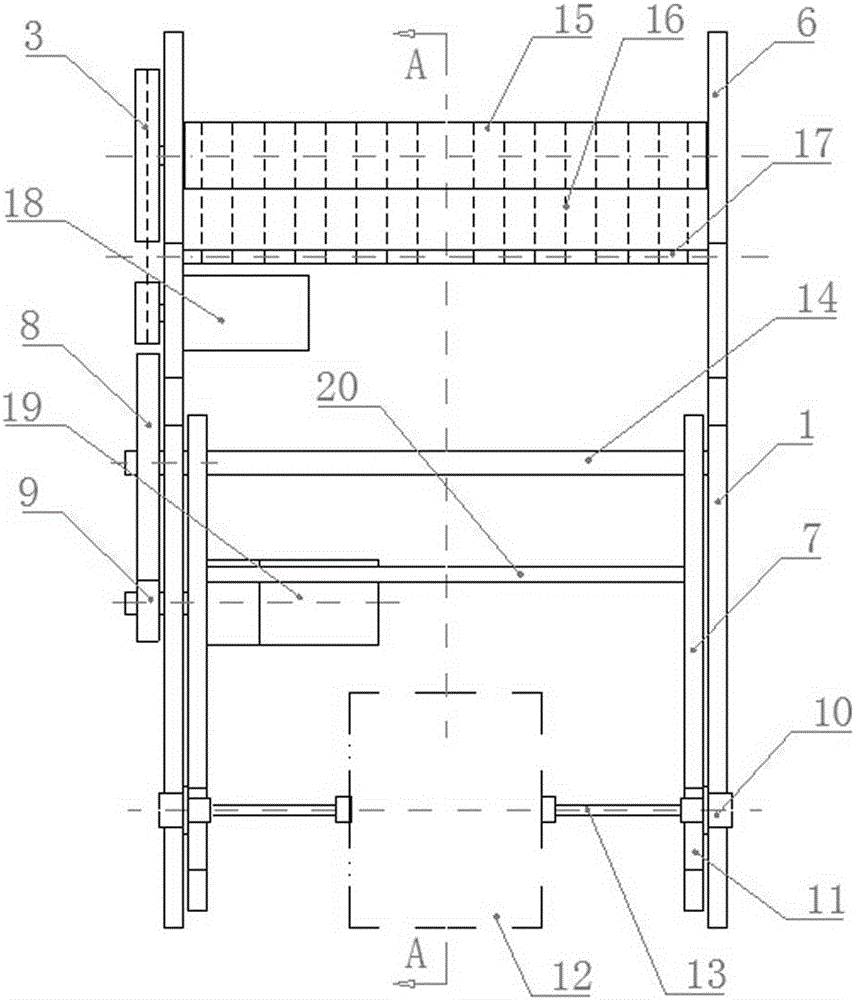

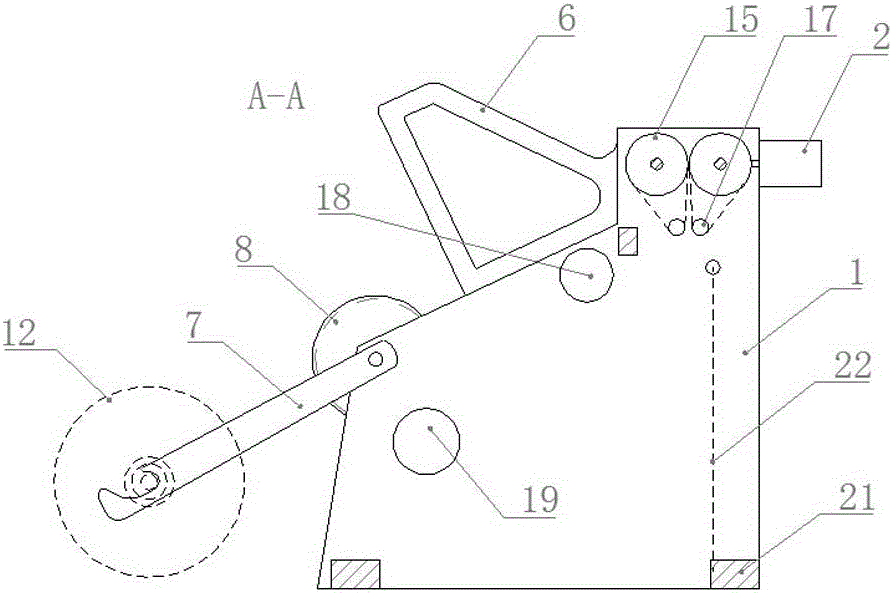

[0018] Such as Figure 1-Figure 8 As shown, a feeding device of a bag making machine in which a swing arm and a guide rail are matched according to the present invention includes a bracket 1 on which a pair of rubber rollers 15 are mounted, and the rubber roller shaft 5 of one of the rubber rollers 15 passes through a timing belt mechanism 3 is connected with the rubber roller driving motor 18 installed on the inside of the support 1 on one side. The rear end of the bracket 1 is hinged with one end of a pair of swing arms 7 through a drive shaft 14, and the other end of the swing arm 7 is provided with a groove 11 with an opening facing upwards (the side shape of the groove 11 is spoon-shaped) ); behind the upper part of the bracket 1, there is a guide rail 6 inclined upwards and backwards (supported by the guide rail support 61 and connected to the bracket 1), the height of the rear end of the guide rail 6 corresponds to the groove 11 on the swing arm 7; The drive shaft 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com