Detachable automotive suspension control arm

A technology of automobile suspension and control arm, which is applied in the direction of suspension, cantilever mounted on the pivot, vehicle components, etc., can solve the problems of waste of resources, inability to separate, increase maintenance costs, etc., to reduce maintenance costs and avoid resources wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

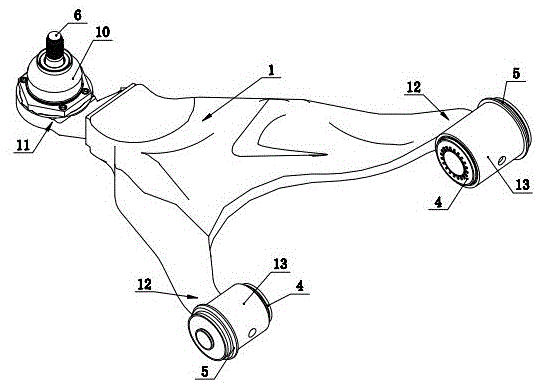

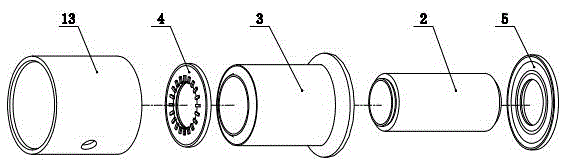

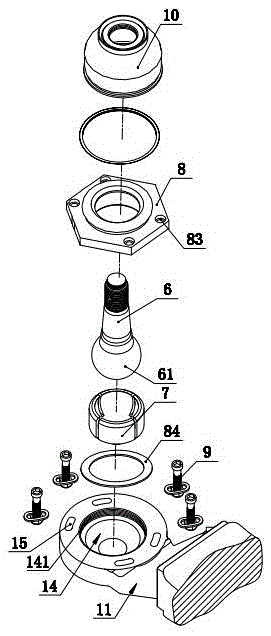

[0013] like figure 1 , 2 , 3, and 4 show a detachable automobile suspension control arm, which includes a control arm body 1, and the control arm body 1 is provided with a ball stud mounting end 11 and a bushing mounting end 12, The bush installation end 12 is provided with a main welded pipe 13, the inner bush 2 and the outer bush 3 are installed inside the main welded pipe 13, and the inner bush 2 is vulcanized and fixed on the outer bush 3. On the inner ring surface, the outer ring surface of the outer bushing 3 is inserted into the main welded pipe 13 with interference, and the axial front and rear ends of the outer bushing 3 respectively pass through the front block 4, the rear block 5 and the main The welded pipe 13 is fixed, and the ball stud mounting end 11 is provided with a ball stud mounting cavity 14, and the ball stud mounting cavity 14 is equipped with a ball stud assembly, and the ball stud mounting cavity 14 is equipped with a ball stud assembly. The assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com