Solid distributor

A dispenser and solid technology, applied in the field of solid dispensers, can solve the problems of difficult connection between solid dispensers and external drives, easy adsorption of solid powder, etc., and achieve high practicability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiment of the present invention provides a solid dispenser, which solves the technical problems in the prior art that solid powder is easily adsorbed on the lower opening wall of the solid powder distribution device, and the connection between the solid dispenser and the external drive is difficult, and realizes the solid powder. Fast, efficient distribution.

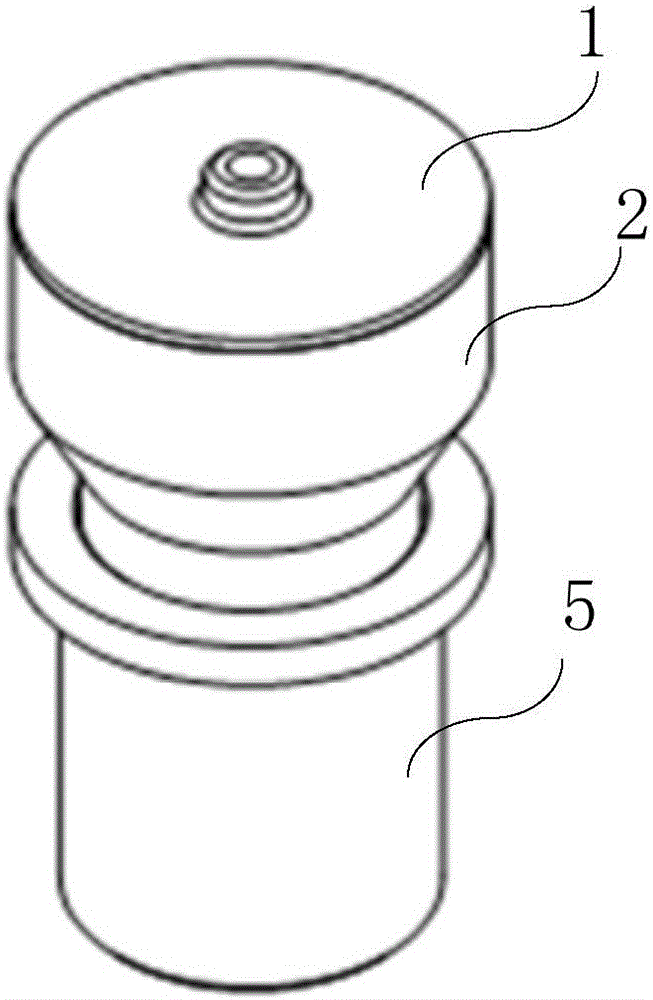

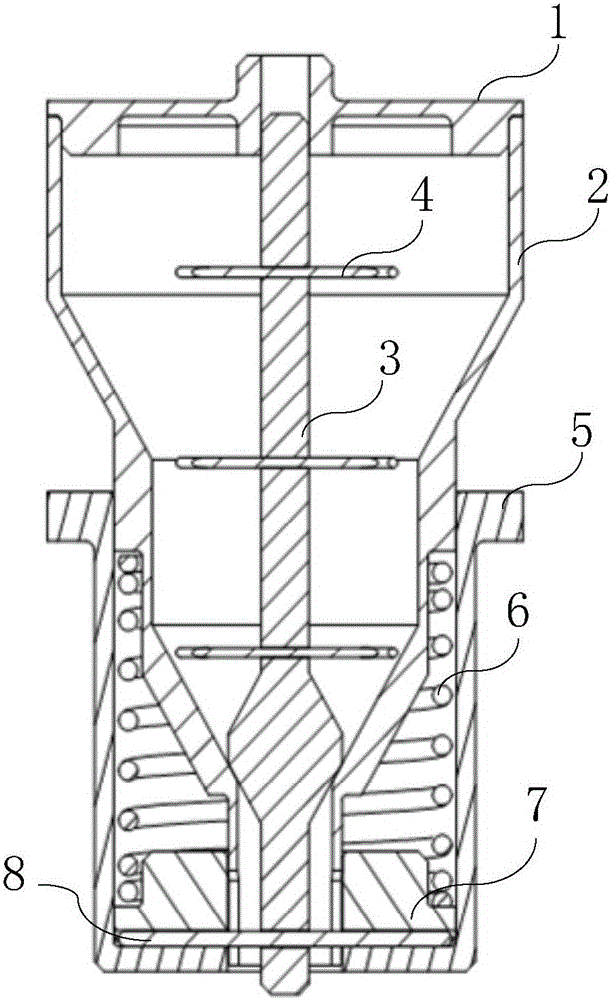

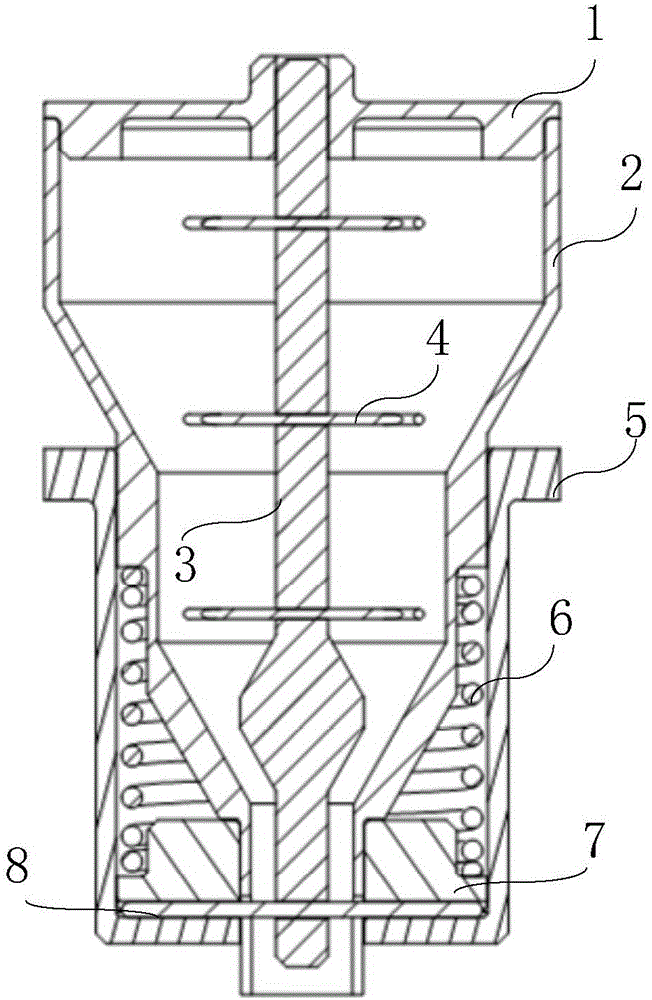

[0032] see Figure 1 ~ Figure 3 , The solid distributor provided by the embodiment of the present invention includes a cover plate 1 , a ball valve 3 , a container 2 , a spring 6 , a baffle plate 7 , a limit shaft 8 and a sheath 5 . see Figure 2 ~ Figure 4 , the inside of the container 2 is a funnel-shaped structure, the cover plate 1 is fixed on the upper end of the container 2, and the cover plate 1 is used to close the upper end of the container 2.

[0033] see Figure 1 ~ Figure 3 , the cover plate 1 is provided with a first guide hole, the ball valve 3 is arranged inside the container 2, the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com