Roadway advanced self-moving type supporting hoisting machine

A self-moving and hoisting machine technology, applied in cranes, mine roof supports, transportation and packaging, etc., can solve the problems of inconvenient movement, poor reliability, small lifting weight of lifting bolts and electric hoists, etc., and achieve the lifting force. Large, easy to move, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific examples the present invention will be further described:

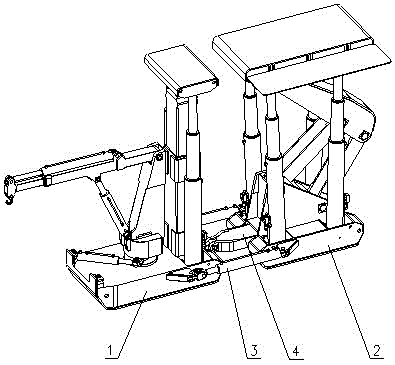

[0018] The present invention relates to a roadway advanced self-moving support hoisting machine, which is characterized in that it includes a hoisting bracket 1, an anchor bracket 2, push-pull jacks 3 installed on the left and right sides between the hoisting bracket and the base of the anchor bracket, and installed behind the hoisting bracket base part and the guide limit rod 4 in the middle of the base of the anchor bracket.

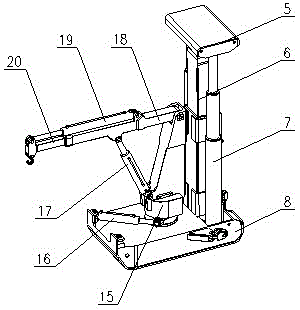

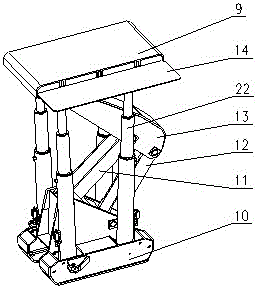

[0019] The lifting bracket 1 includes a lifting mechanism 21, a top beam 5, a telescopic rod 6, and a base 8. The lifting mechanism 21 is installed on the front portion of the lifting bracket base 8, and one end of the telescopic rod 6 is connected to the top beam of the lifting bracket. 5 is hinged, and the other end is inserted into the rear box of the lifting bracket base 8, and two hydraulic columns 7 are arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com