Universal guide rod type hydraulic side-shift distance-adjusting fork used for forklift

A universal, forklift technology, applied in the direction of lifting devices, etc., can solve the problems of inconvenient disassembly and assembly of oil pipes, affecting the appearance, and complicated procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

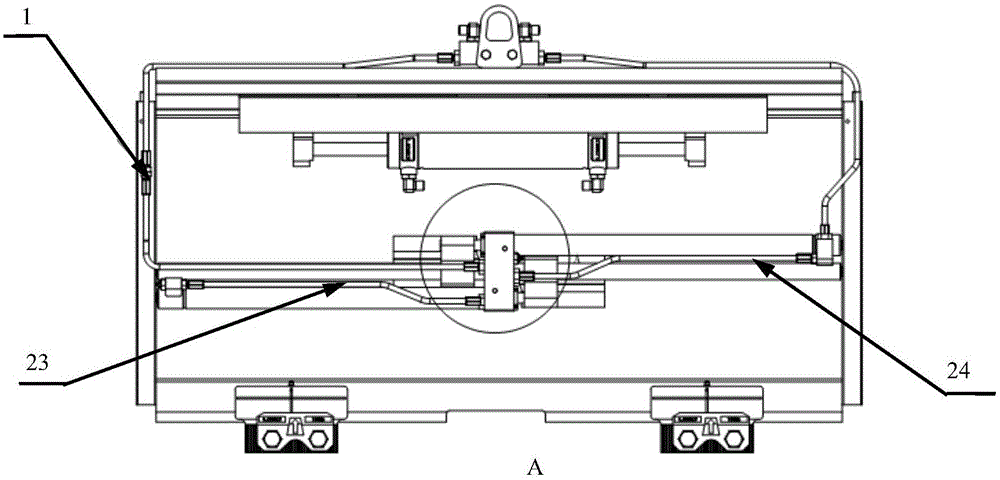

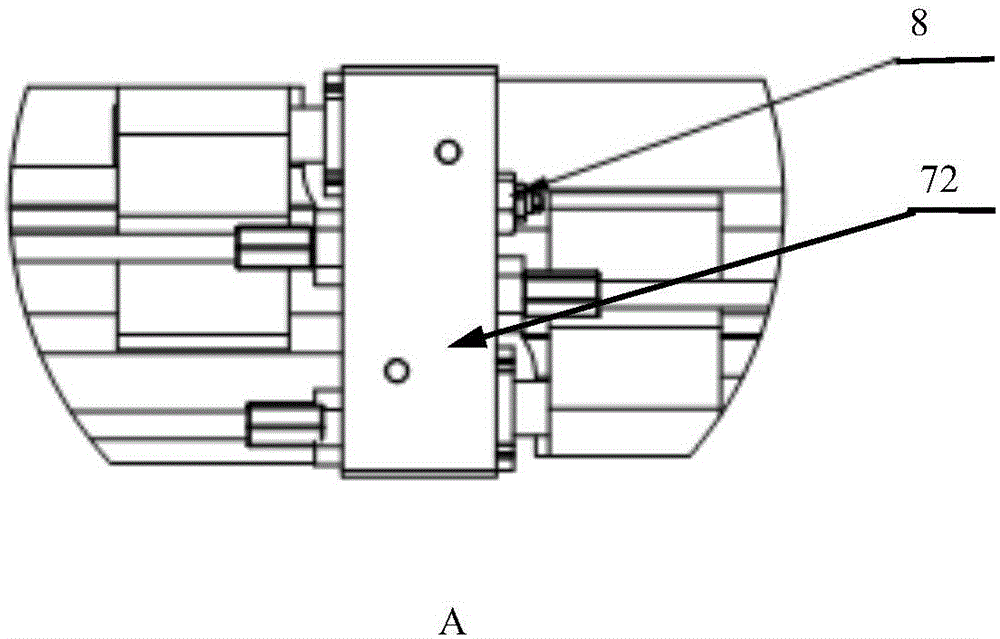

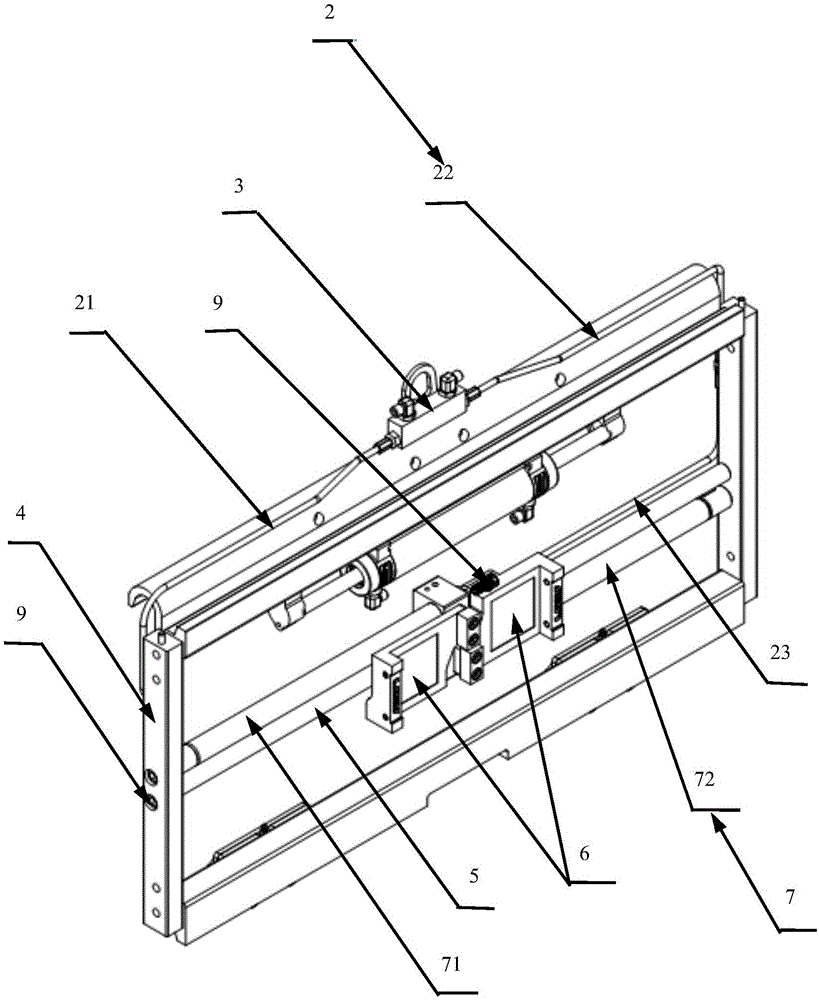

[0015] like Figure 1-4 As shown, a universal guide rod type hydraulic side shift distance adjusting fork for a forklift, including a shift fork assembly 6, a distance adjustment cylinder 7, a support rod 5, a cross 3 and a side shifter 4; the side shifter 4 The whole is a rectangular frame structure, the inner middle of the side shifter 4 is horizontally installed with the support rod 5, and the distance adjustment cylinder 7 is installed on the support rod 5; the distance adjustment cylinder 7 includes a pair of hydraulic cylinders 71 , a coupling sleeve assembly 72, a joint and oil pipeline 2, the pair of hydraulic cylinders 71 are relatively arranged above the left part and below the right part of the support rod 5 and parallel to the support rod 5, so The left end of the left hydraulic cylinder 71 and the right end of the right hydraulic cylinder 71 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com