Device for stretching and cutting two-to-sliver

A sliver-forming device and tow technology, which is applied in the direction of fiber bundles becoming fiber sliver/yarn, etc., can solve the problems of poor gear transmission accuracy, easy rusting of adjusting screw, large gear backlash, etc., and achieve easy adjustment and lubrication. Better effect, less gear backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

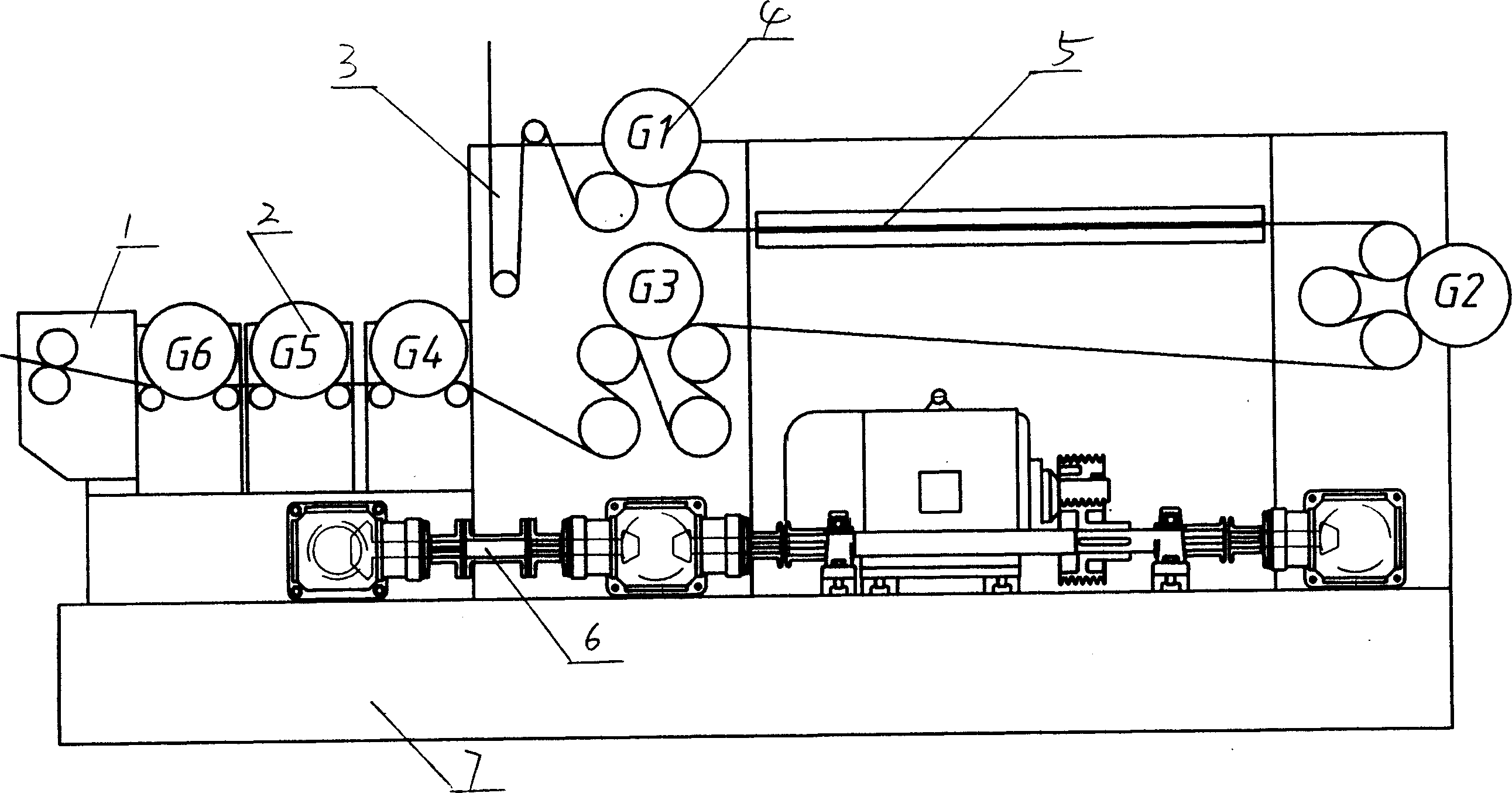

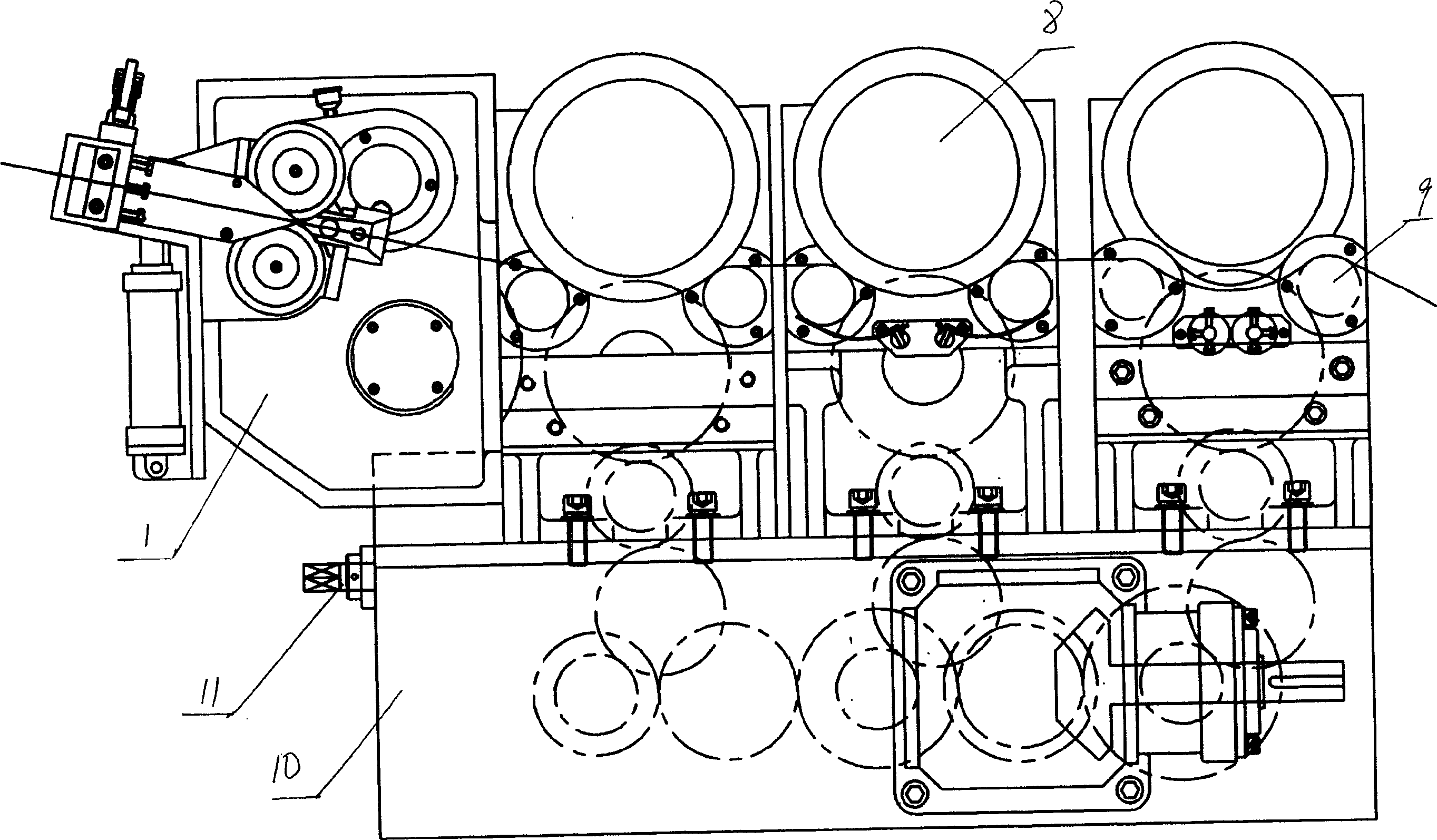

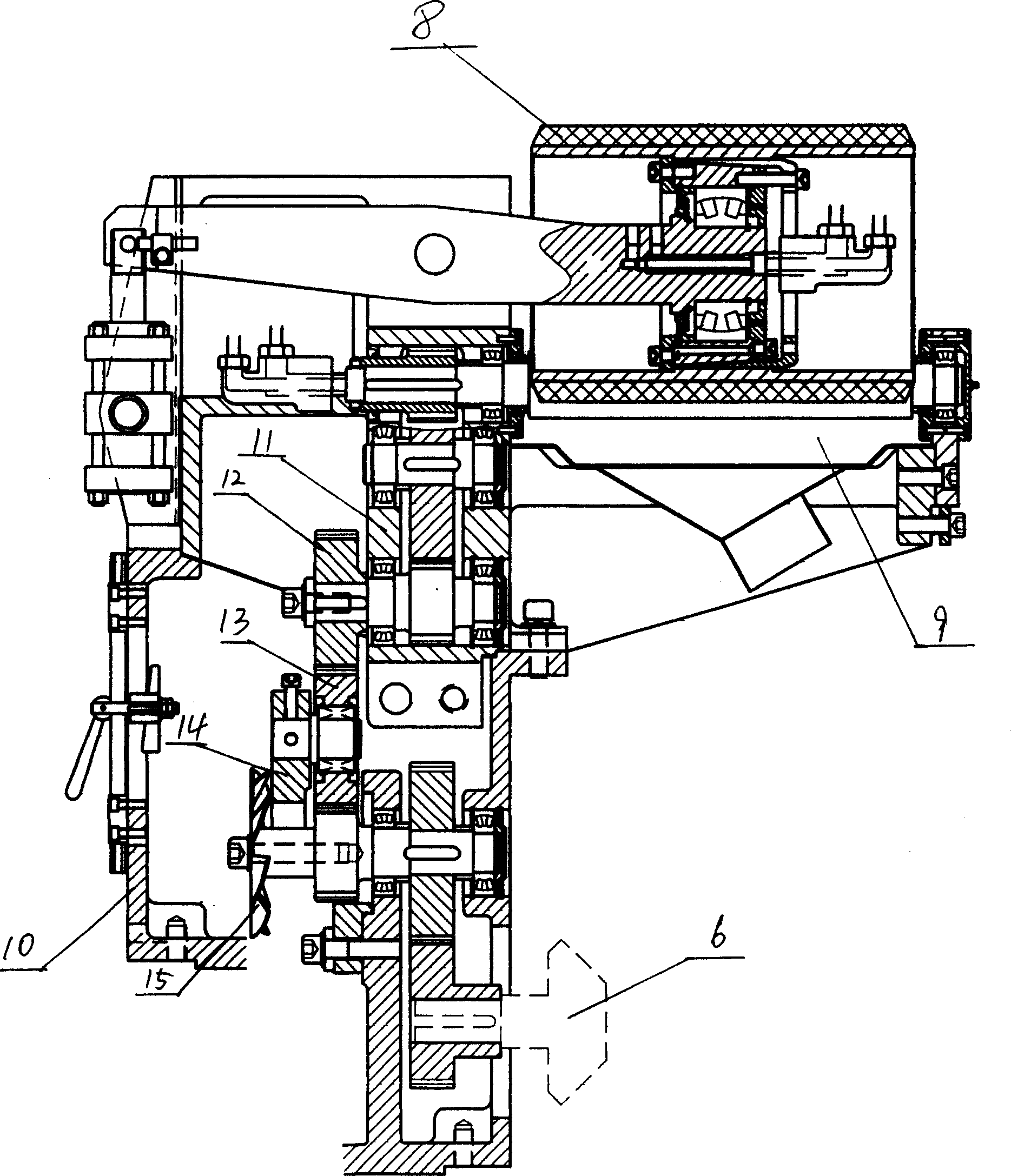

[0016] A kind of tow stretching device, which includes a stretching zone composed of three pre-drawing heads 4, a stretching zone consisting of three main drafting heads 2, two pre-drawing zones before the stretching zone There is a heating plate 5 between the heads; there is a tow feeding device 3 before the drawing zone; after the breaking zone, there is a fiber sliver output device 1 that is broken and directly formed into strands; each drafting head has a hydraulic pressure Loaded floating rotary pressure roller 8 and two traction rollers 9 close to the pressure roller 8, the first main drafting head is the fixed drafting head 16 fixed on the frame 7, and the remaining main drafting heads 17, 18 are The sliding drafting head is installed on a slideway 20 successively, and a transmission box 10 is provided below the slideway 20, and a screw nut adjusting device 22 is provided at the bottom of the sliding drafting head 17, 18; Power gears 19 are fixedly installed in the box ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com