Position-adjustable textile machine needle seat

An adjustable needle seat technology, which is applied in textiles and papermaking, deburring devices, fiber processing, etc., can solve the problems of inability to adjust the position of the needle row, the position of the machine needle, and the poor effect of textile materials, etc., to achieve convenience The effect of installation, good promotion and utilization value, and expansion of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

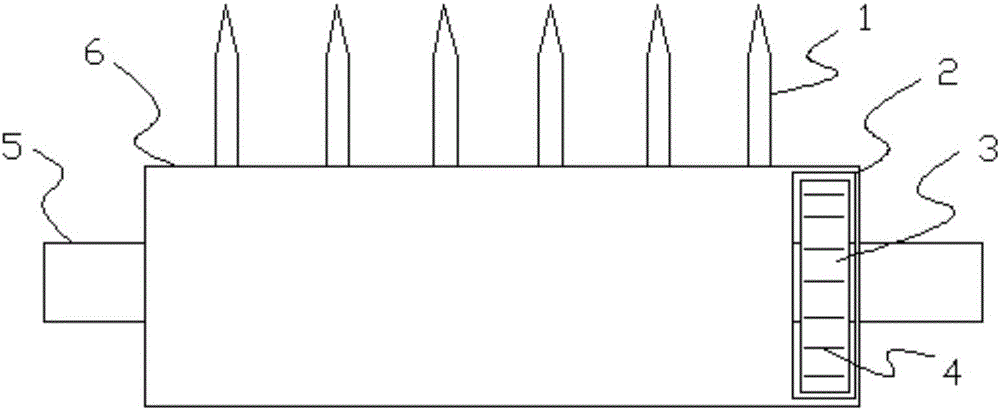

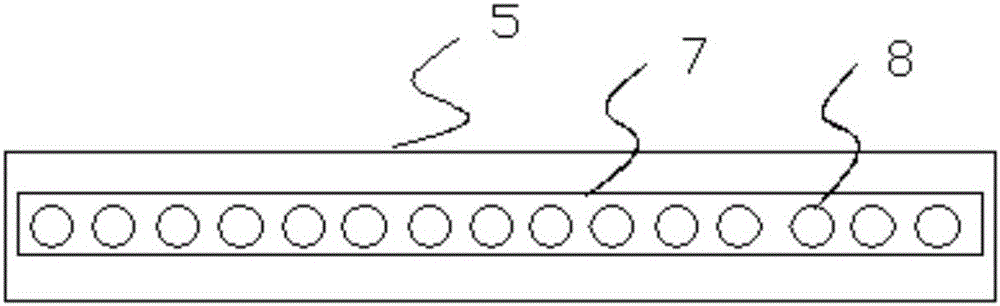

[0020] Such as figure 1 , figure 2 , image 3 As shown, the structure of the position-adjustable textile machine needle holder includes a machine needle 1, a support 6 and a needle fixing rod 5, and an adjustment knob 3 is embedded in one side of the support 6, and the adjustment knob 3 is arranged on a In the lateral groove 2, the middle axis of the adjusting knob 3 is provided with a first screw hole (shown in the figure), and the needle fixing rod 5 is provided with a screw thread matched with the first screw hole (in the figure). not shown). When in use, the relative position of the machine needle can be adjusted by turning the adjusting knob, which adapts to different textile materials and expands the scope of application.

[0021] In the above embodiment, specifically, a strip-shaped blind hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com