Independent driving method of engraving function based on embroidery machine head

An independent drive, embroidery machine technology, applied in the direction of embroidery machine mechanism, embroidery machine, automatic control embroidery machine, etc., can solve the problems of increasing the failure rate, high production efficiency, reducing equipment service life, etc., to improve the smoothness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

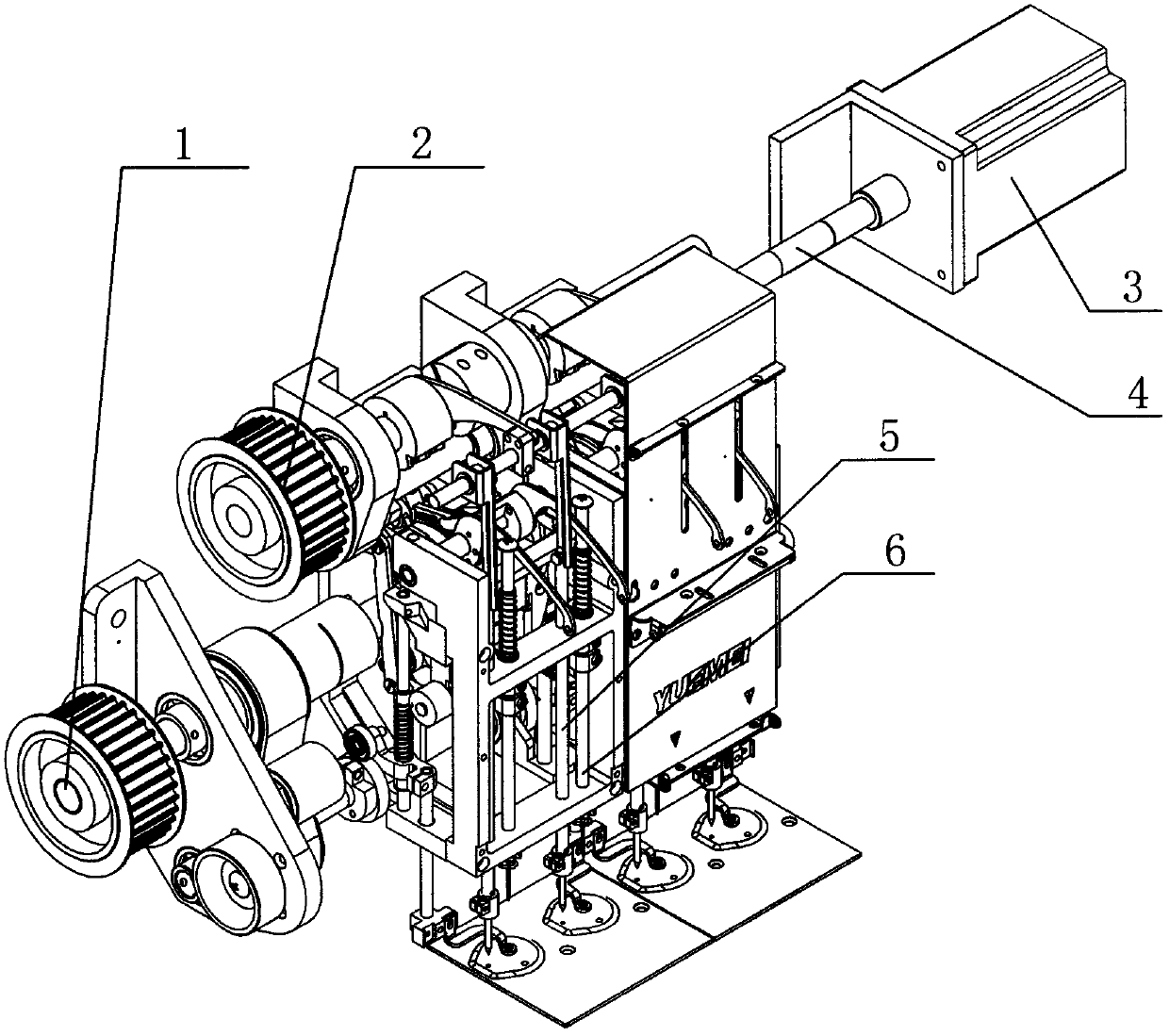

[0036] An independent driving method for engraving function based on embroidery machine head, comprising the following steps:

[0037] 1. Cancel the original color-changing box device on the head of the embroidery machine or cancel the color-changing function of the original color-changing box device on the head of the embroidery machine about the carved hole;

[0038] 2. Through the main shaft on the head of the embroidery machine, the main shaft drives the needle bar to move up and down through the driving system of the needle bar;

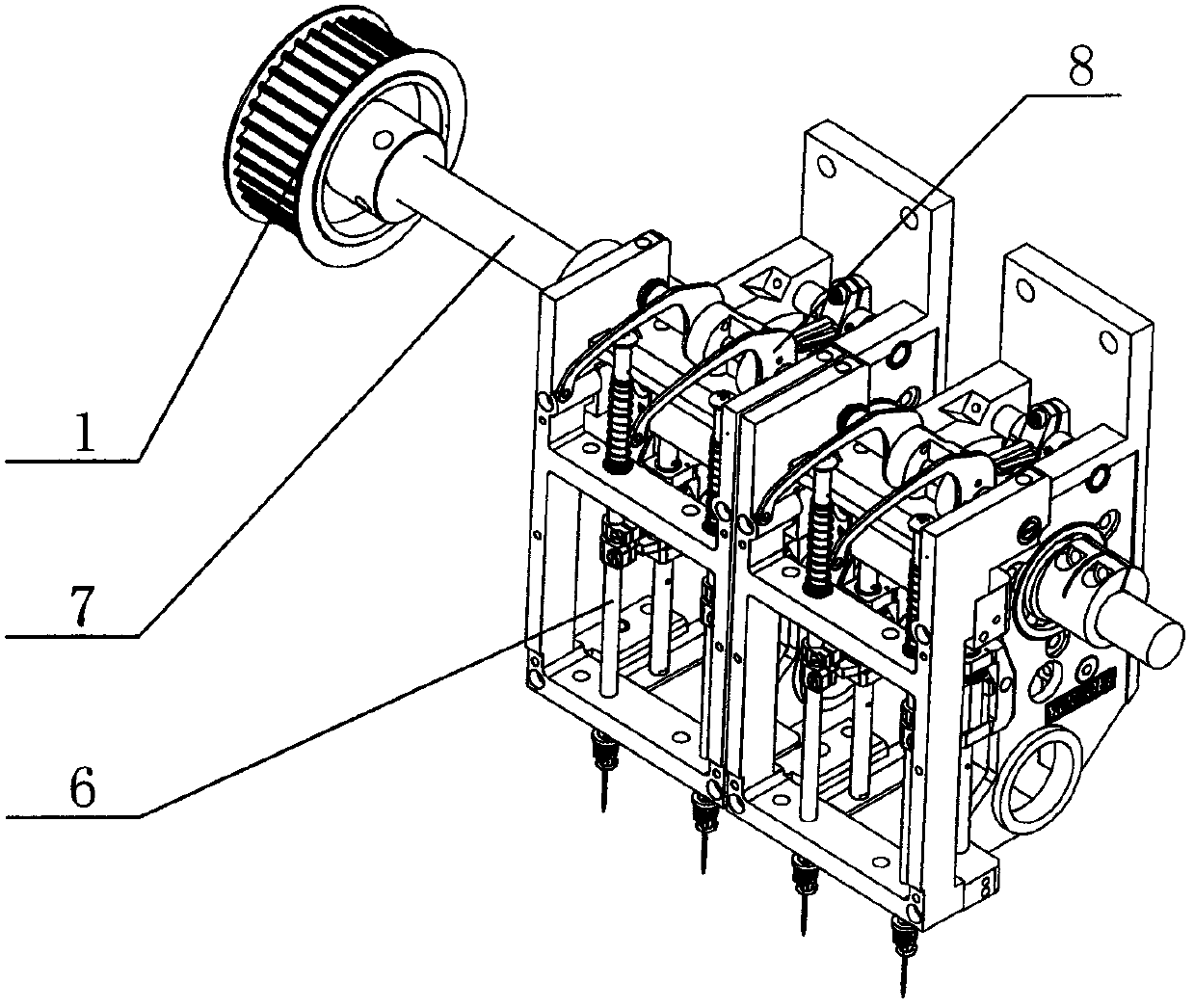

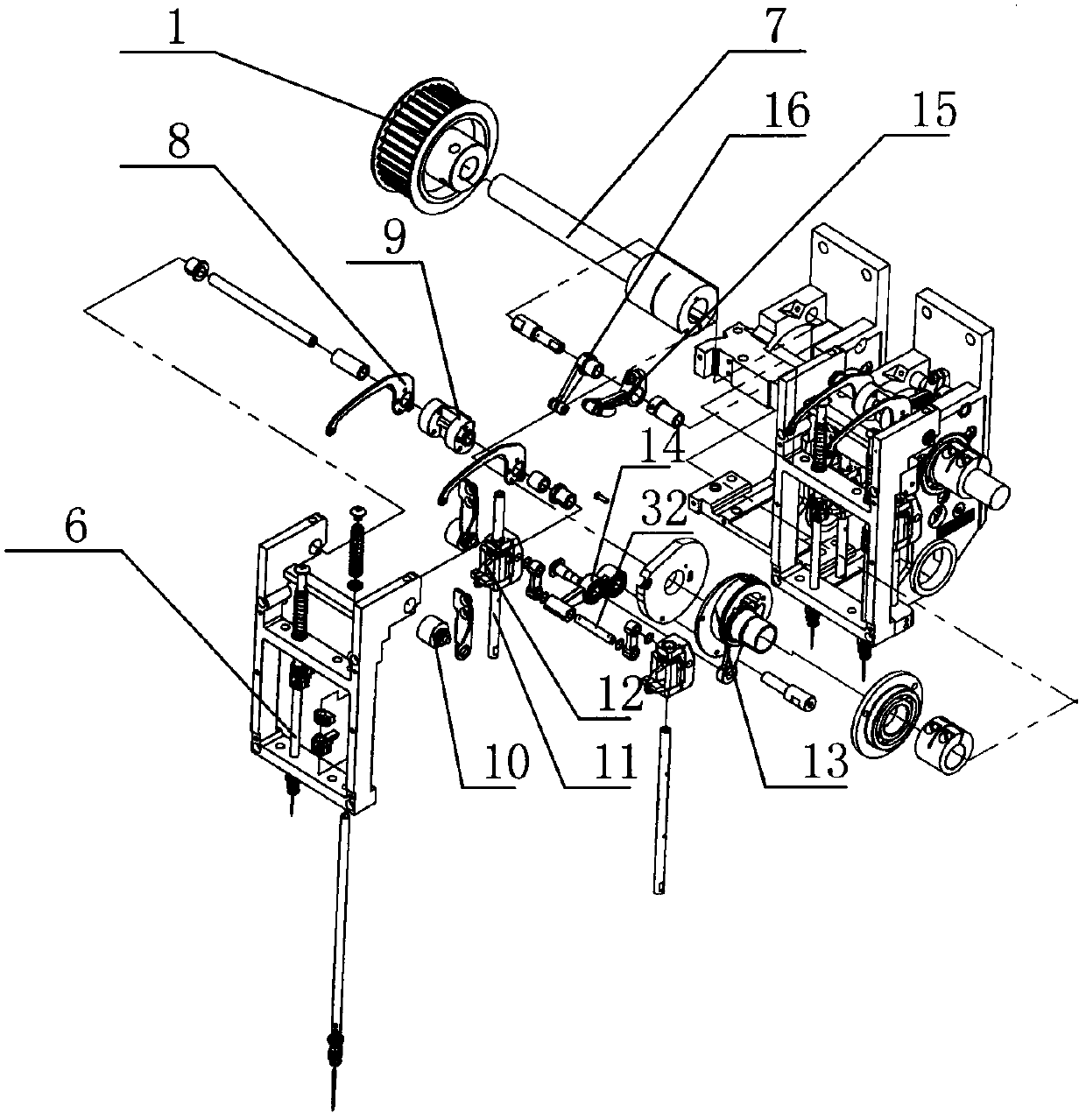

[0039] 3. Set up an independent engraving motor, which drives the engraving knife to move up and down through the drive system of the engraving knife; the drive system of the engraving knife in step 3 includes the engraving drive shaft driven by the engraving motor, and the engraving drive The hole-engraving rocker arm is installed on the shaft, and the hole-engraving rocker arm is connected with the hole-drilling tool bar through the transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com