Urban comprehensive pipe rack of steel corrugated plate structure

A technology of integrated pipe gallery and corrugated plate, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve the problems of long construction period and high investment cost, and achieve the effect of fast construction speed, accelerated construction and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in combination with specific embodiments.

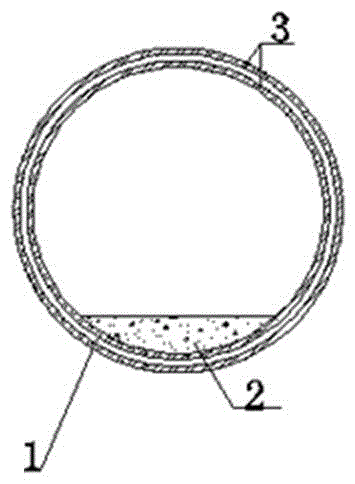

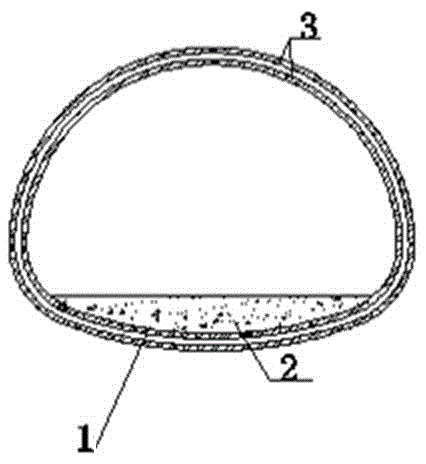

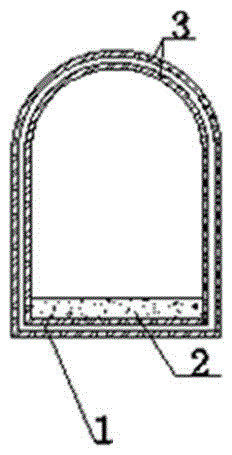

[0025] The present invention relates to a steel corrugated plate structure urban comprehensive pipe corridor, in which steel corrugated plates 8 are spliced vertically and horizontally to form a steel corrugated pipe 1 in a foundation pit, which is used as the main body of the corridor. The cross-section of the corrugated steel pipe 1 as the main body of the corridor is circular, pipe arched or horseshoe-shaped. The inner bottom surface of the steel bellows 1 is provided with a concrete layer 2, and the corresponding thickness is set according to the construction requirements, so that the bottom is a horizontal plane, which facilitates the arrangement of internal pipelines.

[0026] The thickness of the corrugated steel plate 8 is between 3 mm and 10 mm, and the splicing holes 4 of steel corrugated pipes are arranged on the peripheral edges, and are fixed by splicing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com