Sprayer assembly of concrete gunniting vehicle and concrete gunniting vehicle

A technology of spraying trucks and concrete, which is applied in earthwork drilling, processing of building materials, wellbore lining, etc. It can solve the problems of large impact and friction, increased stress on the nozzle assembly, and increased twisting of pumping hoses, etc. problem, achieve the effect of reducing impact and friction, prolonging service life and increasing bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

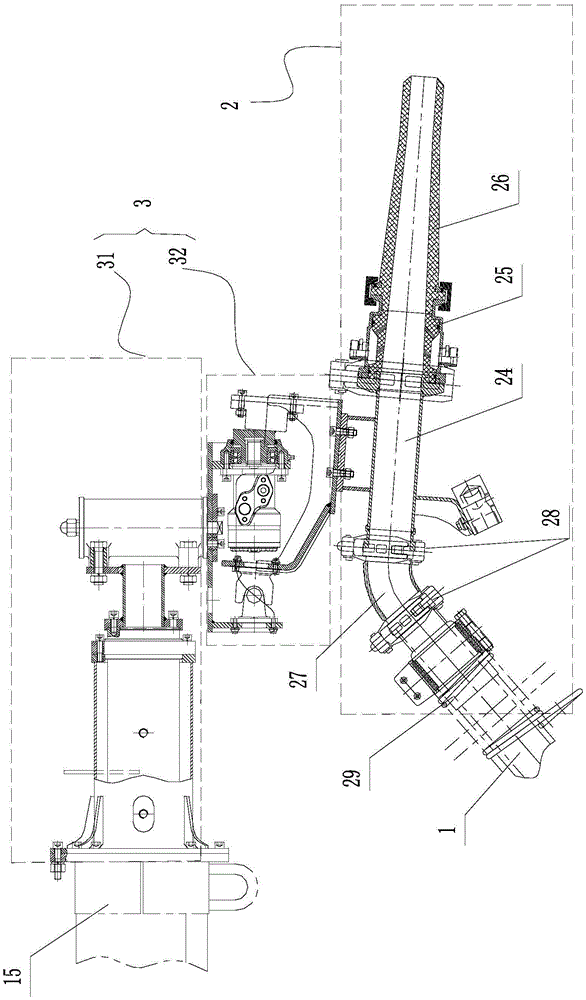

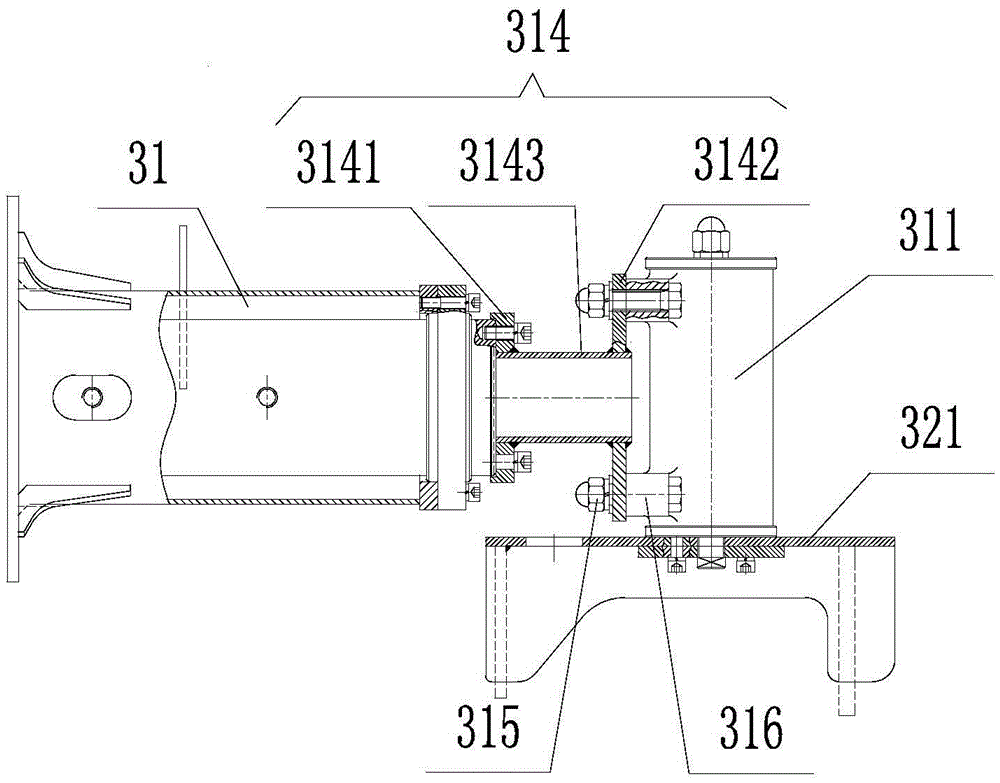

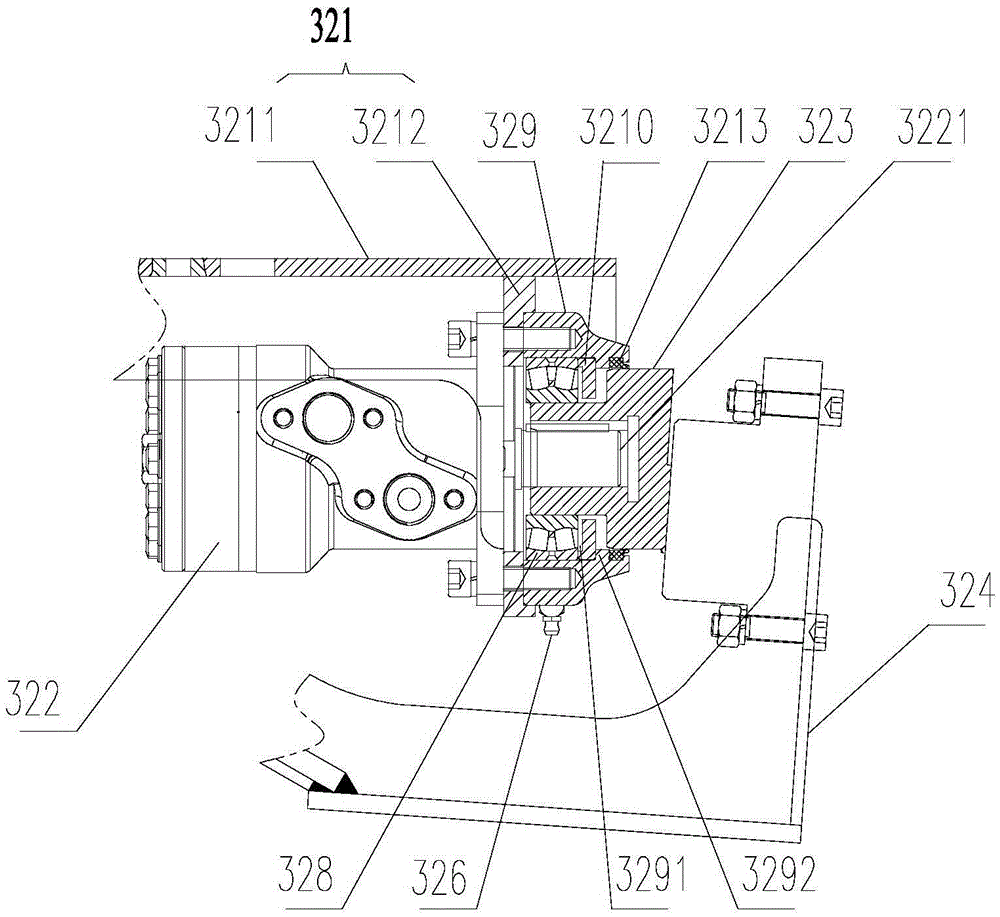

[0031] Such as figure 1 As shown, the nozzle assembly of the concrete spraying vehicle provided by the present invention includes a spraying device 2 connected to the pumping hose 1 and a driving device 3 for driving the spraying device 2, and the spraying device 2 includes A connecting pipe 24 , a mixer 25 and a nozzle 26 , the side wall of the connecting pipe 24 is connected to the driving device 3 . One end of the connecting pipe 24, the mixer 25 and the nozzle 26 are sequentially connected, and the other end of the connecting pipe 24 is rotatably connected with one end of the elbow 27, and the other end of the elbow 27 The pumping hose 1 is rotatably connected.

[0032] The concrete spraying truck sends the concrete from the hopper into the pumping pipeline. Under the pressure of the pump, the concrete is transported along the pumping pipeline to the pumping hose 1 at the end of the pumping pipeline, and finally enters the injection device 2. , the concrete passes throug...

Embodiment 2

[0061] After the concrete shotcrete truck is used, the pumping pipeline must be cleaned quickly. In order to clean the pumping pipeline more conveniently, this embodiment makes the following improvements on the basis of the first embodiment:

[0062] Such as Figure 4 As shown, in this embodiment, a stop valve 216 is added to the spray head assembly of the concrete spraying vehicle described in the first embodiment, and a spray head assembly with a stop valve 216 is provided.

[0063] The injection device 2 in the first embodiment further includes a cut-off valve 216, and the two ends of the cut-off valve 216 are sealed and fixedly connected with the mixer 25 and the nozzle 26 respectively. Specifically, the shut-off valve 216 includes a shut-off valve housing 217, a sealing ring 218, a shut-off valve spool 219 and a rotary switch 220 arranged outside the shut-off valve housing 217, and the shut-off valve spool 219 is arranged on the The spherical structure inside the shut-of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com