Screw ball pump

A ball and screw technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., can solve the problems of complex processing technology, fast stator wear, high manufacturing cost, etc., and achieve the effect of strong transmission capacity, small fluctuation, and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

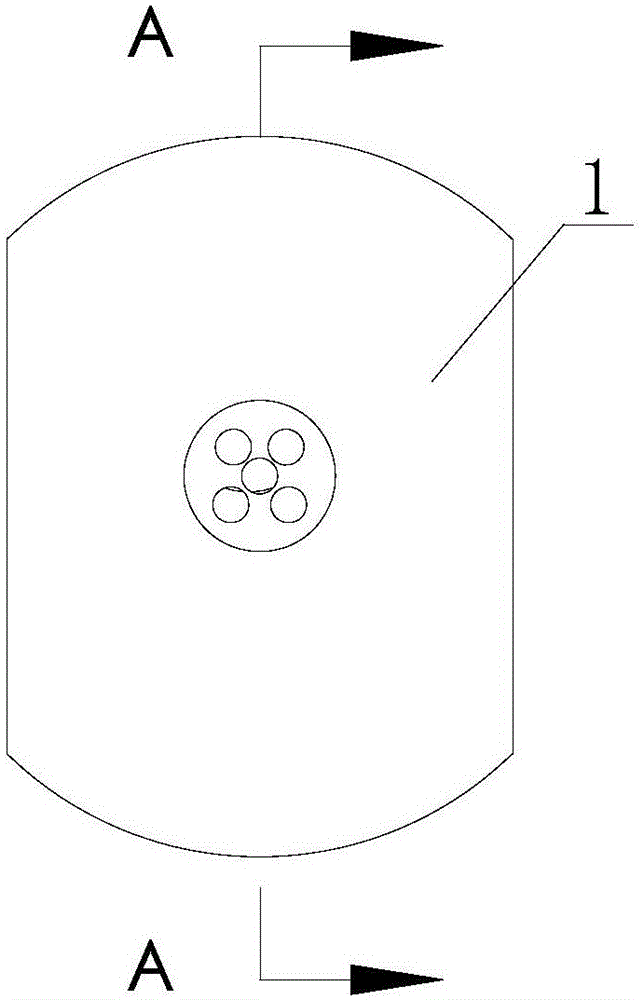

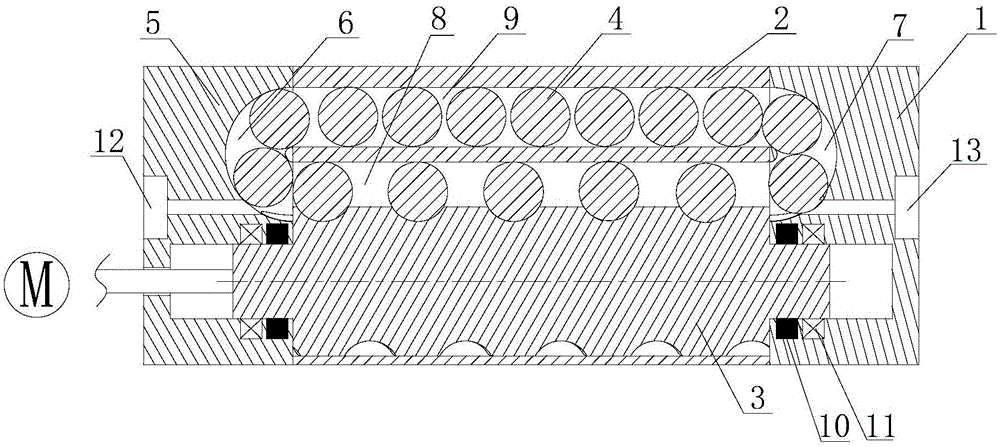

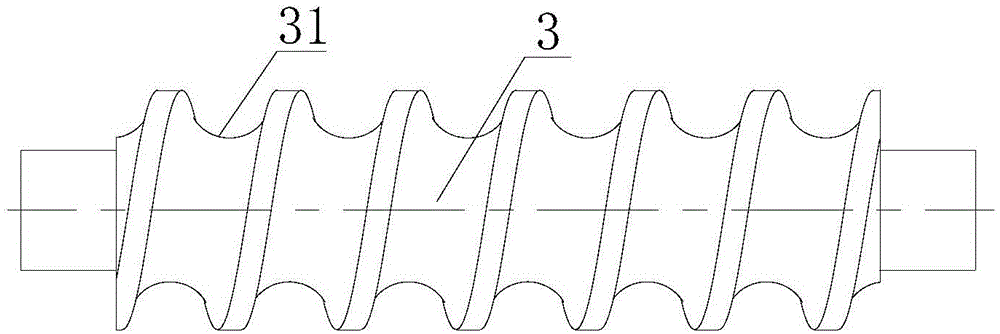

[0023] Such as Figure 1 to Figure 5 As shown, a helical ball pump includes a stator 2 and a rotor 3. The stator 2 is provided with a rotor accommodation cavity 21, and the rotor 3 is provided with a helical guide groove 31. The helical guide groove 31 is an arc-shaped tooth shape with a fixed pitch. Both ends of the stator 2 and the rotor 3 are respectively provided with a first end cover 5 and a second end cover 1 , and the first end cover 5 and the second end cover 1 support the rotor 3 through a bearing 11 .

[0024] In this embodiment, the spiral guide groove 31 is an arc-shaped tooth with a fixed pitch. In other embodiments, the pitch of the spiral guide groove 31 is variable, or the tooth shape is non-arc, which can achieve the same technical effect. .

[0025] In this embodiment, the stator 2 is provided with a first ball accommodation chamber 8 con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap