Implantable pole sleeve butt joint structure and cabinet adopting implanted pole sleeve joint structure

An implanted, rod-sleeve technology, applied in the field of cabinets, can solve the problems of unsatisfactory surface quality of finished products, limited surface aesthetics, and sunken furniture panels, and achieves simple and stable assembly process, good connection effect, and fewer knocks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

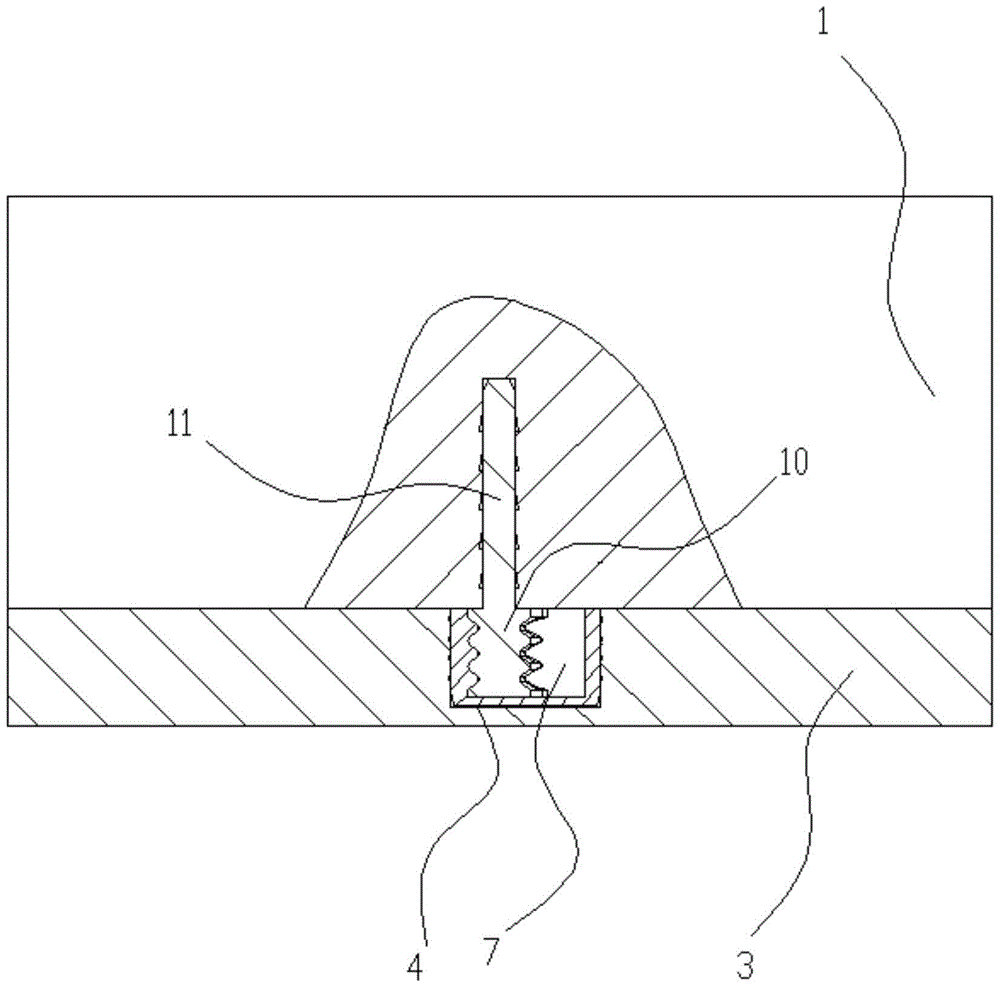

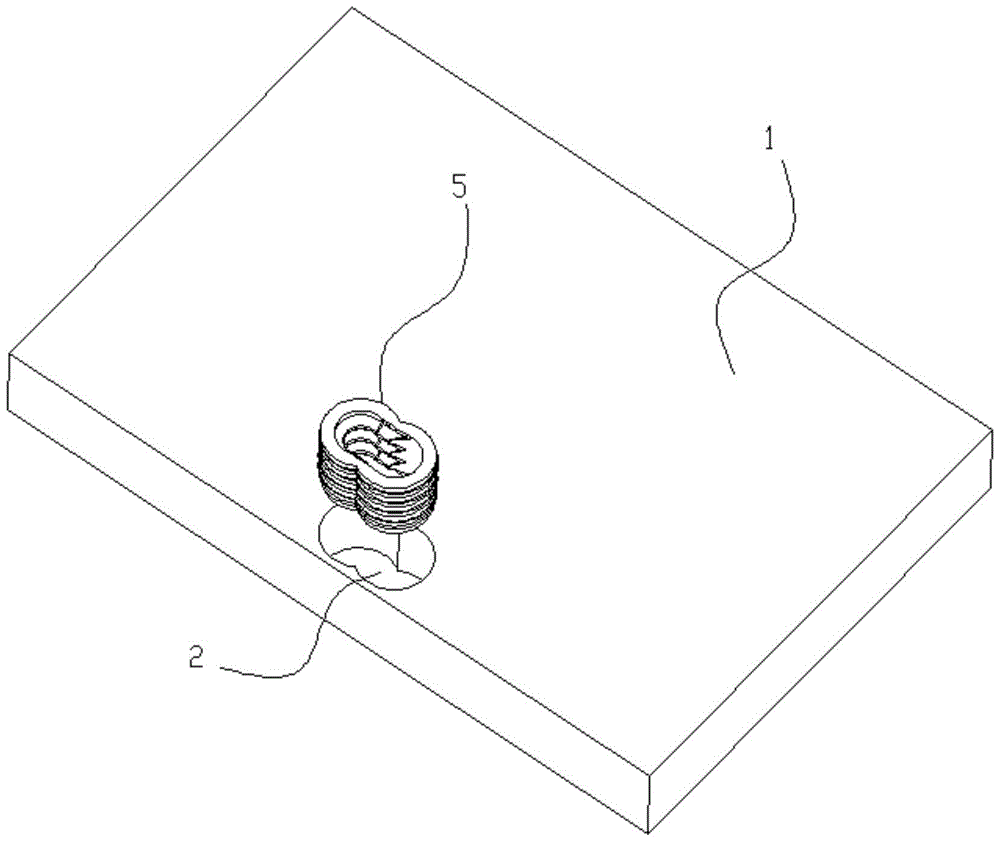

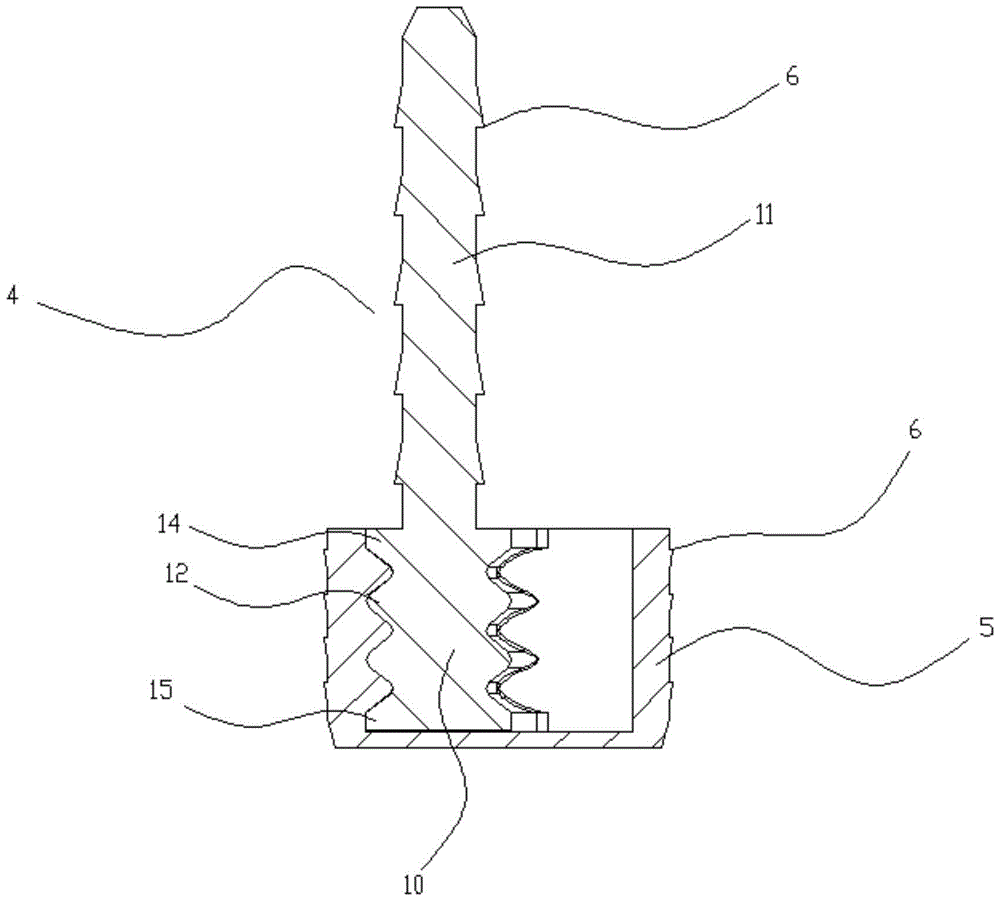

[0028] Such as Figure 1 to Figure 9 In the shown embodiment, an implantable rod sleeve docking structure includes an insert groove 2 provided on the first plate 1, a convex piece groove provided on the second plate 3, and the insert groove is provided with The connecting kit, the protruding part groove is provided with implanted convex parts 4, the connecting kit includes the buckle base sleeve 5, and the outer wall of the buckle base sleeve is provided with a number of connection barb rings 6, and the connection on the buckle base sleeve The barb ring and the side wall of the insert groove are pressed against each other. The buckle base sleeve is provided with a buckle groove. There are several C-shaped buckles 9 arranged in parallel in the half groove, and the space between adjacent C-shaped buckles is a snap-in gap. The implanted convex pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com