Coaxial bidirectional stirring device

A two-way stirring, coaxial technology, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of ineffective treatment of the cell wall of the agitated material, and the effect of agitation is not obvious, so as to achieve compact structure and high efficiency , Reduce the effect of rotational friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

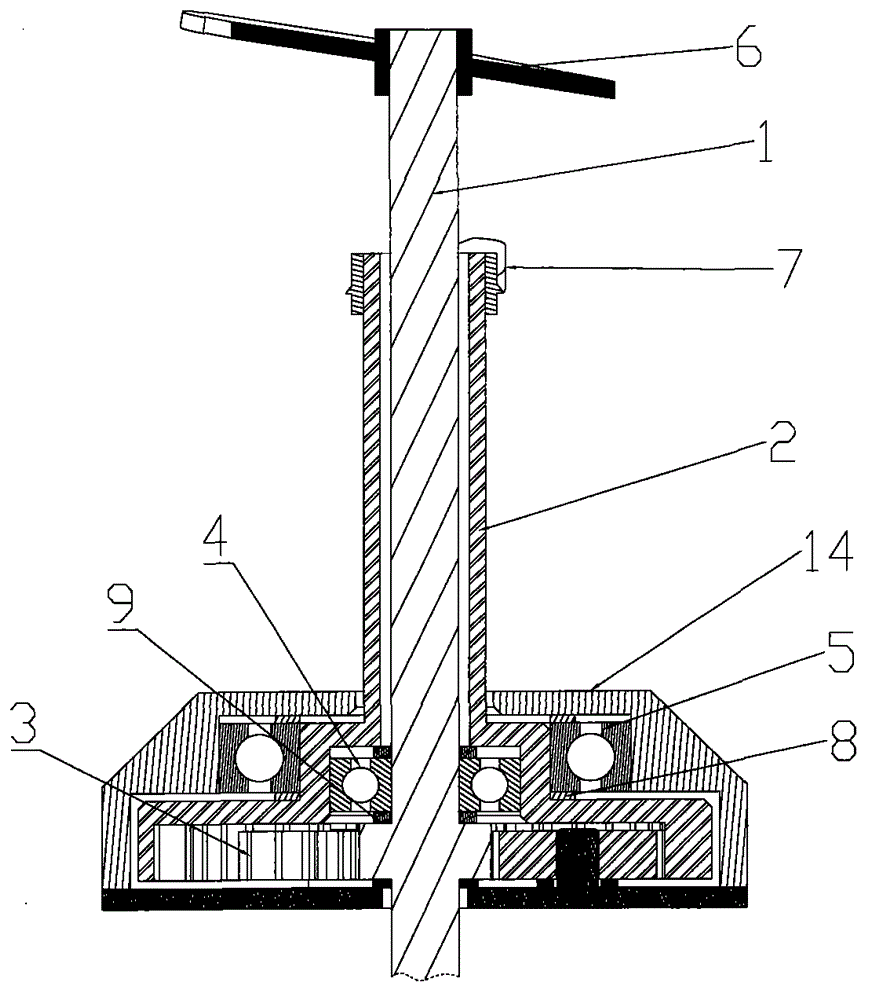

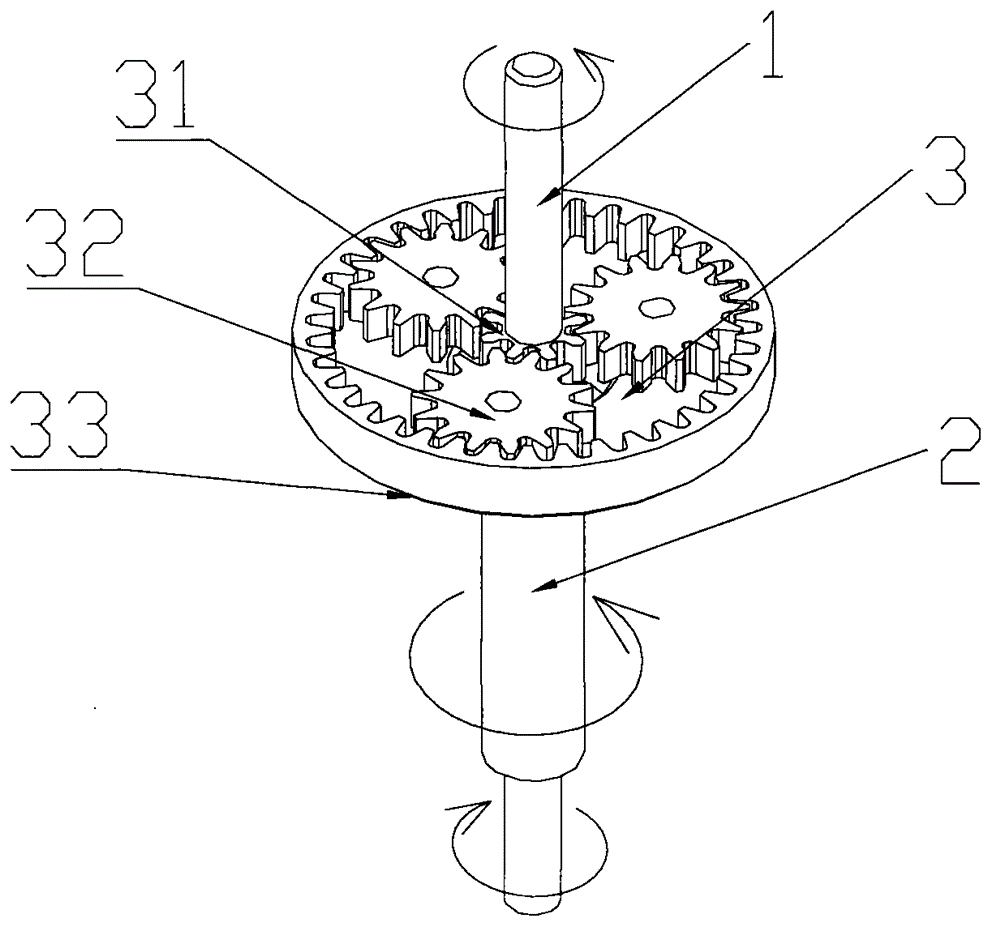

[0019] like image 3 As shown, a motor 12 is provided below the coaxial two-way stirring device, and the inner rotating shaft 1 is coaxially connected with the motor 13, and the motor 13 and the rotating shaft shell 14 are covered with an organic casing 12, and the inner rotating shaft 1 and the outer rotating shaft 2 There is a stirring container 10 on the top. When in use, the object is placed in the stirring container 10, and the motor 13 is turned on to realize the reverse variable speed stirring of the first stirring blade 6 and the second stirring blade 7. The stirring is full and efficient, and the After the stirring is completed, the stirring blade part can be disassembled through the connecting part 11, which is convenient for the user to clean.

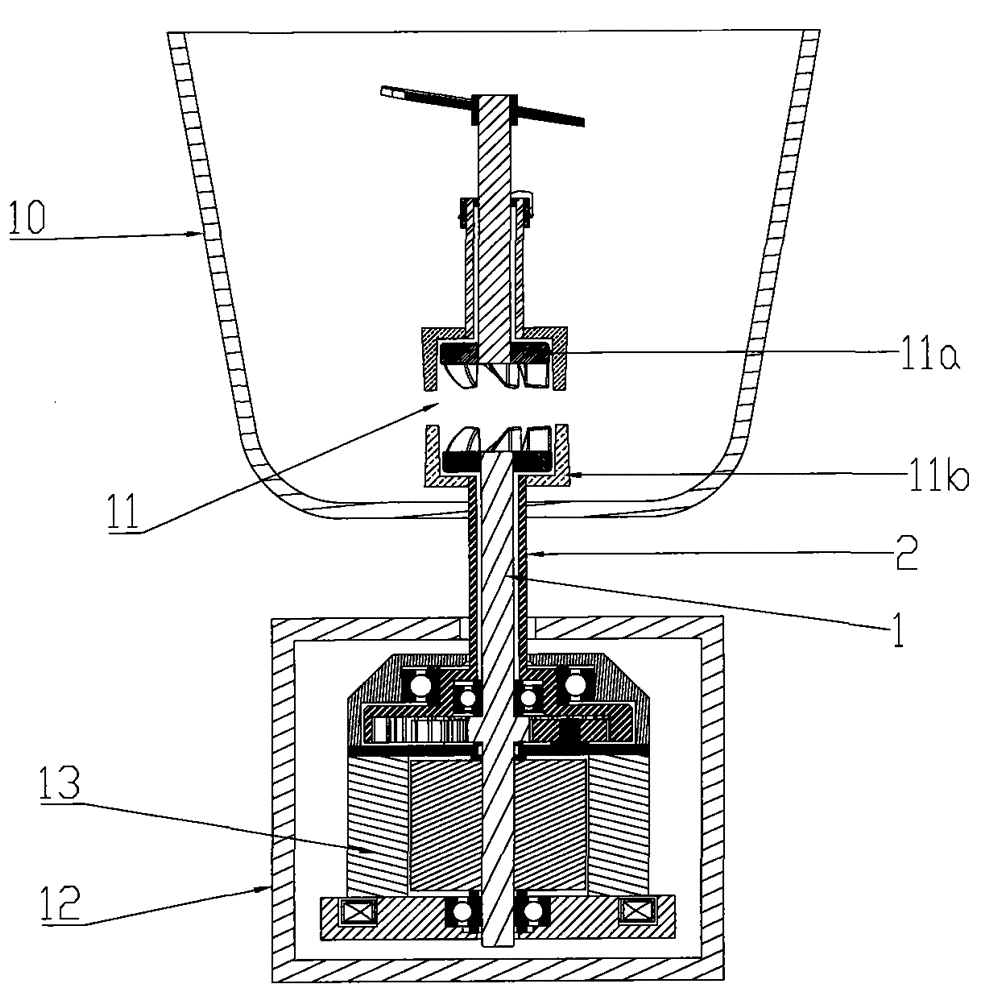

Embodiment 2

[0021] like Figure 4 As shown, the coaxial two-way stirring device is connected with a motor 12 and is sheathed with a casing 12 for fixing, a sealing ring is provided at the connection between the casing 12 and the outer rotating shaft 2, and a blade protective cover 15 is arranged on the outer rotating shaft 2, The blade protection cover 15 prevents the stirring blade from touching the mixing container 10, and has a through hole on the side wall of the blade protection cover 15 to increase the circulation of the stirring material and improve the stirring efficiency. , it is convenient for the user to hold and operate, and the casing 12 can be turned upside down during use, so that the stirring blade can penetrate into the stirring container 10 for stirring, which is convenient to operate and easy to clean.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com