Rapid steam hot pot

A steam and fast technology, applied in the direction of steam generation, steam generation method, steam cooking utensils, etc., can solve the problems of large energy consumption, high steam pressure, steam escape, etc., and achieve the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. The following embodiments are used to illustrate the present invention, but not to limit the scope of the present invention.

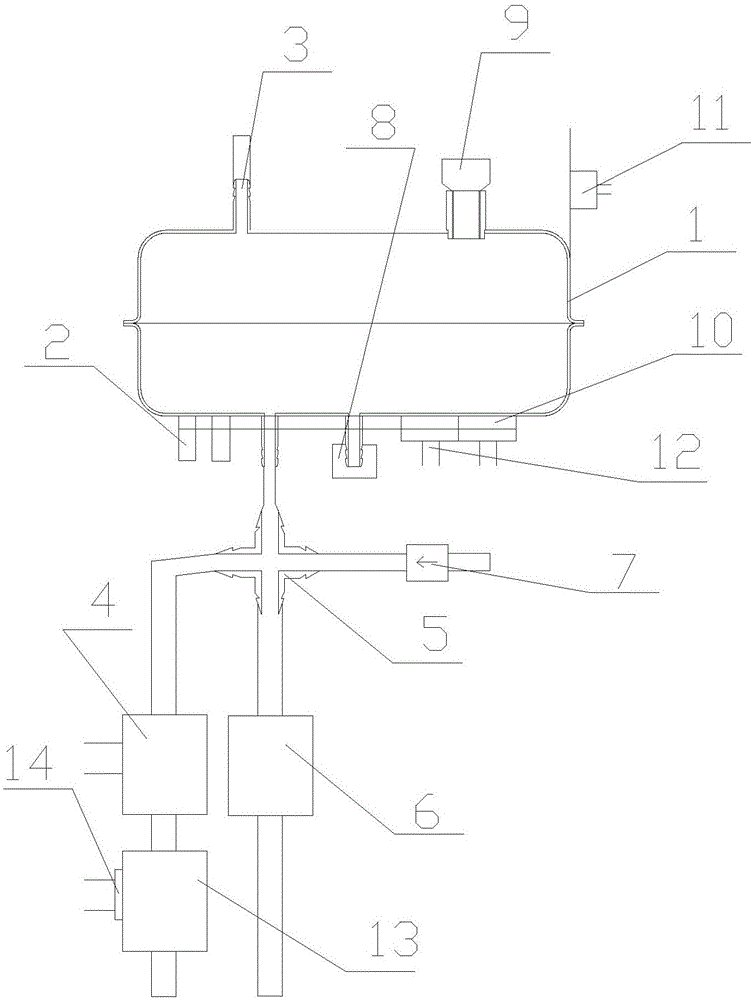

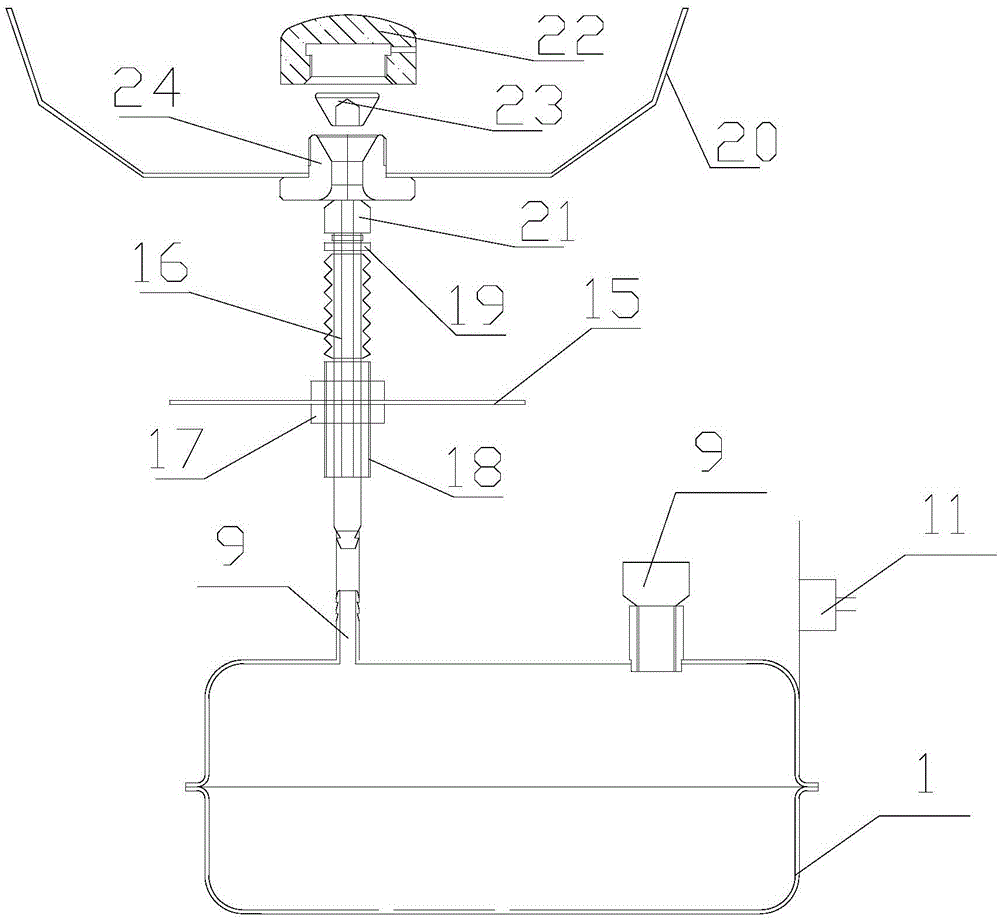

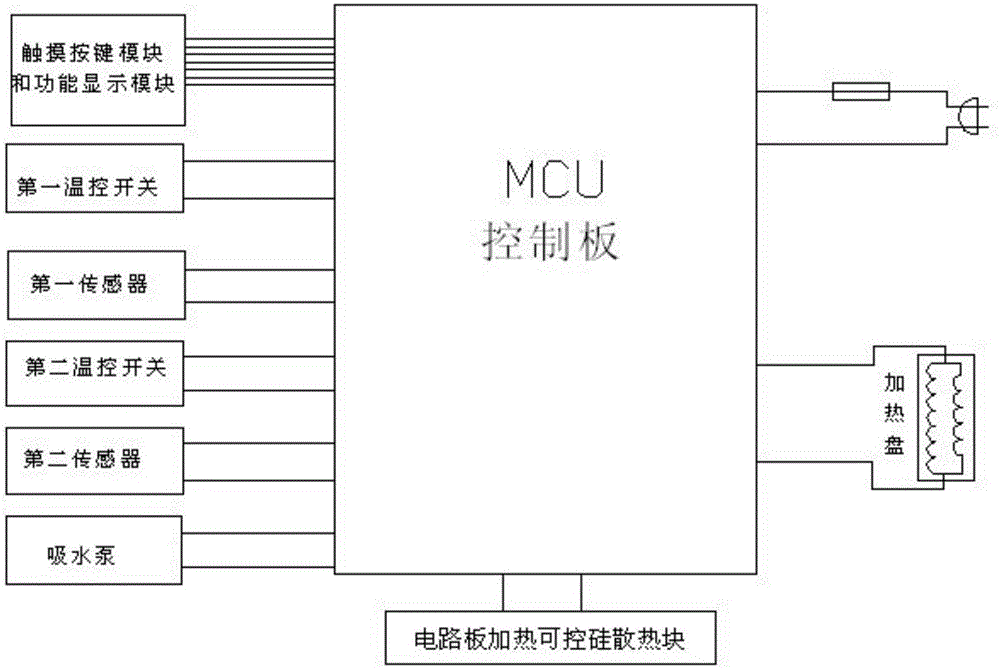

[0026] Such as figure 1 and 2 As shown, the instant steam chafing dish of the present invention comprises a lower pot body (not shown in the figure), an upper pot body 20 that is adjustable and connected with the lower pot body, and the upper pot body 20 is provided with a nozzle, and the lower pot body A boiler 1 is provided for drawing in cold water and heating the drawn in cold water in time and sending out the generated steam in time, the top of the lower pot body is provided with a connection fixing plate 15 to cover the boiler 1 in the lower pot body; the boiler 1 is provided with a heating plate 2 that can immediately heat the cold water pumped into the boiler and generate steam; the boile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com