Beam crack fault detection apparatus and apparatus based on frequency sweep frequency sweep excitation vibration

A technology for fault detection and vibration excitation, which is used in measuring devices, testing of mechanical components, testing of machine/structural components, etc. It can solve problems such as low crack sensitivity, high requirements for theoretical analysis and operating skills, and achieve broad engineering applications. Prospects, the effect of the realization process is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

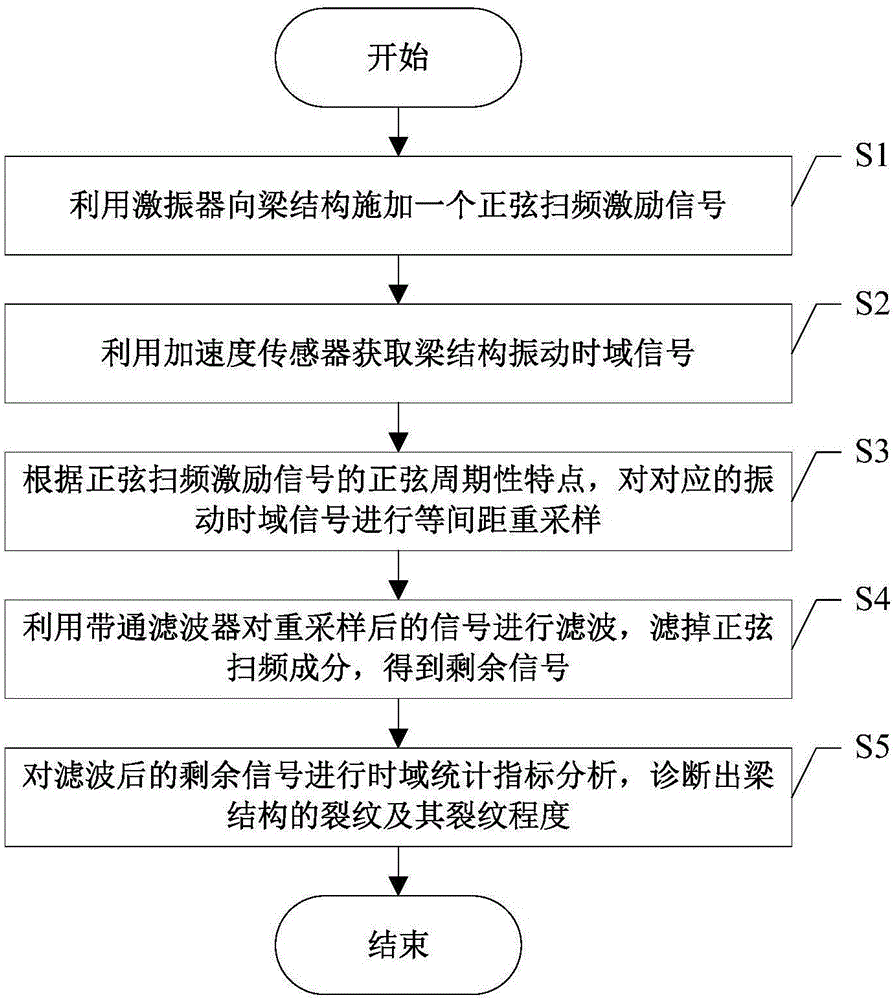

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

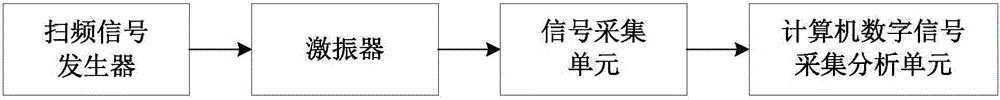

[0033] The invention provides a beam crack fault detection device based on sweep frequency excitation vibration, such as figure 1 As shown, it includes a signal acquisition unit, a frequency sweep signal generator, an exciter, and a computer digital signal acquisition and analysis unit, and the frequency sweep signal generator, an oscillator, a signal acquisition unit, and a computer digital signal acquisition and analysis unit are connected in sequence.

[0034] Among them, the frequency sweep signal generator is used to generate the sine frequency sweep excitation, and the vibrator is used to realize the excitation process. The frequency sweep signal generator is connected to the vibrator through a high-power cable to realize the sinusoidal frequency sweep excitation to the beam structure.

[0035] The signal acquisition unit is connected with the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com