Automatic concentration control sulfur dioxide test box

A sulfur dioxide and test chamber technology, which is applied in various fluid ratio control, measuring devices, instruments, etc., can solve the problems of not being able to more truly reflect the test requirements, the automation program is not high, and it cannot be realized, and the test effect is true and reliable. High degree of automation and the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

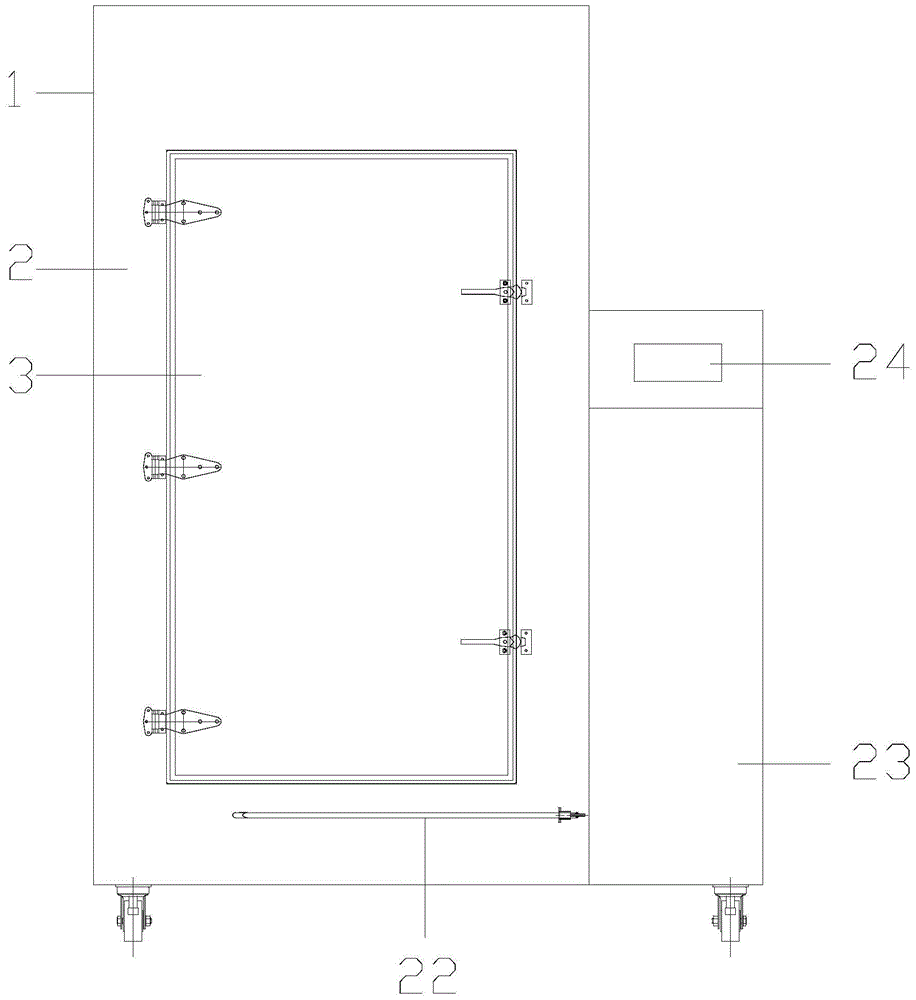

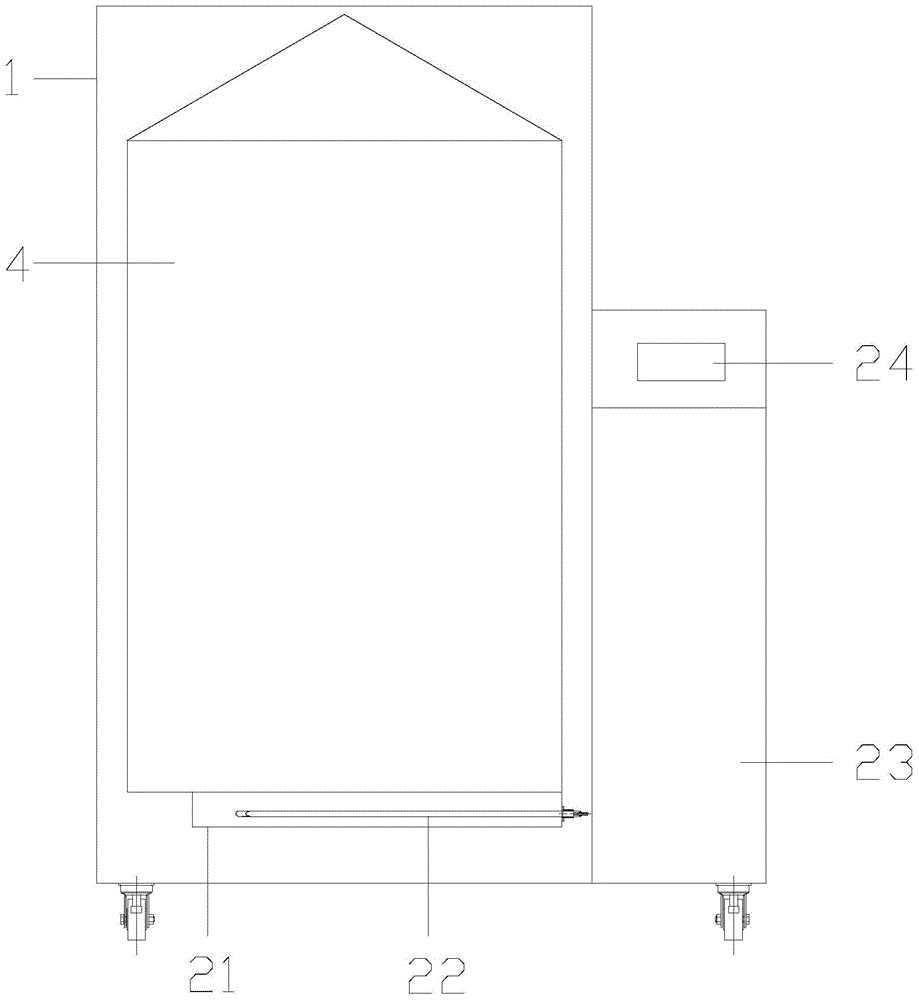

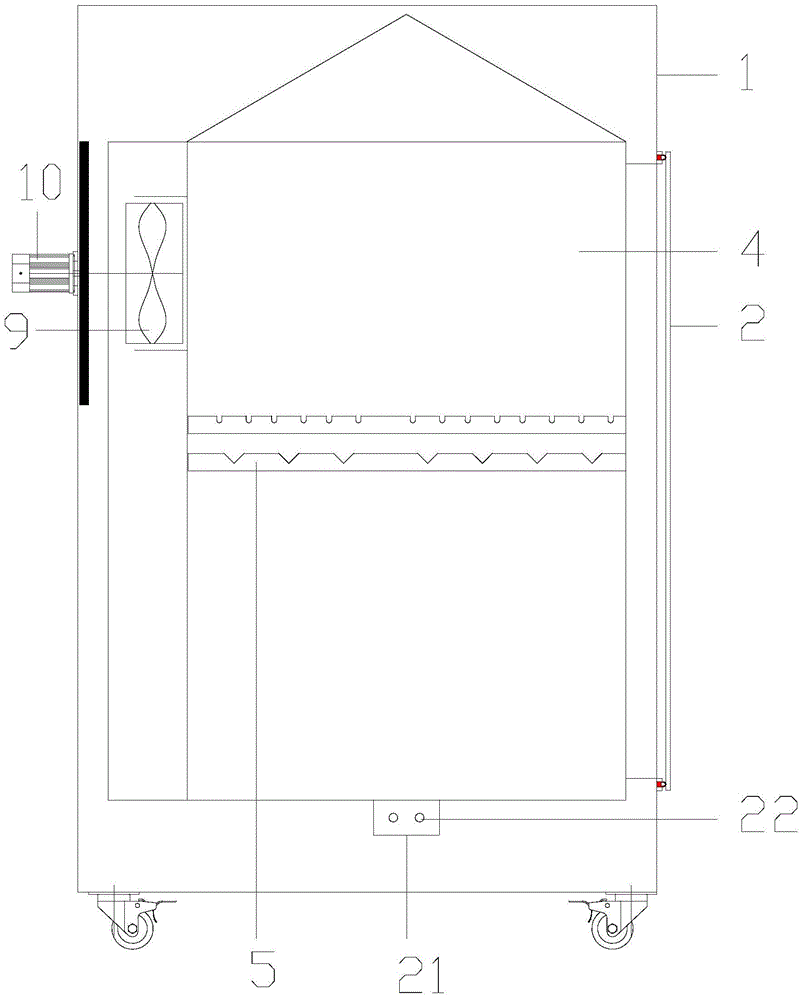

[0034] As shown in the accompanying drawings, the present invention includes: a box body 1, a box door 2 is provided on the front end of the box body 1, the box body 1 and the box door 2 are sealed and connected, and the box door 2 is provided with an observation window 3, which is convenient for testing Observing the test condition of the test sample at any time, the box body 1 is provided with a working room 4, and the inner wall of the working room 4 is equipped with a left-right symmetrical sample holder 5, which also includes an inflation system, a concentration detection system and a heating system. The inflation system is connected to work through an air guide The air charging port 6 of the chamber 4, the concentration detection system is connected between the detection port 7 and the air return port 8 of the working room through the air duct, and the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com