Crude oil storage tank corrosion monitoring device

A technology for corrosion monitoring and crude oil storage tanks, which is applied in the field of corrosion monitoring devices for crude oil storage tanks, can solve problems such as inaccurate test data, and achieve good technical results and small deviations in corrosion analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

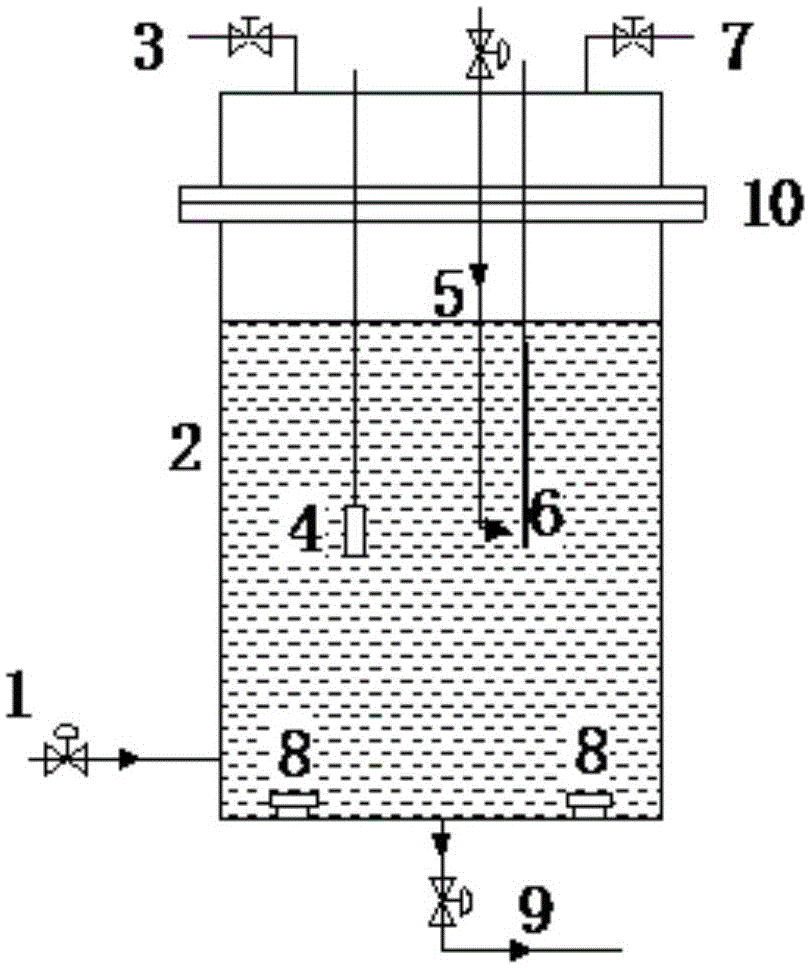

[0017] A crude oil storage tank corrosion monitoring device, comprising a storage tank body 2, on which an experimental liquid inlet 1, a liquid outlet 9, a gas inlet 3, and a gas outlet 7 are opened, and a corrosion coupon 4 and a corrosion coupon are hung on the top of the tank. The corrosion monitoring electrode 6 is connected with a deoxygenated water flushing pipe 5 near the corrosion monitoring electrode 6, and sacrificial anodes 8 are arranged at the bottom of the tank, and the number of sacrificial anodes is calculated according to the above formula. The experimental liquid inlet 1 is connected to the tank bottom water discharge pipeline of the crude oil storage tank through a pipeline.

Embodiment 2

[0019] According to the conditions described in Example 1, only according to the needs of the experiment and the actual situation, a taper not greater than 5° can be applied to the tank bottom plate in the tank body 2 .

Embodiment 3

[0021] According to the conditions described in Example 1, according to the experimental needs and actual conditions, a heating device and a heat preservation device are provided outside the storage tank body 2 to keep the temperature inside the tank at a constant value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com