Leaky cable wrapping forming method

A technology of leaky cables and forming methods, applied in the direction of marking conductors/cables, manufacturing cables/conductors, insulating conductors/cables, etc., to achieve the effects of avoiding cross-folding, simple structure, and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

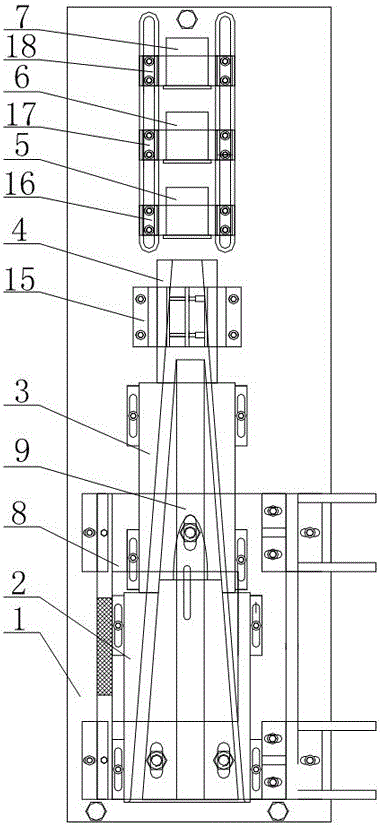

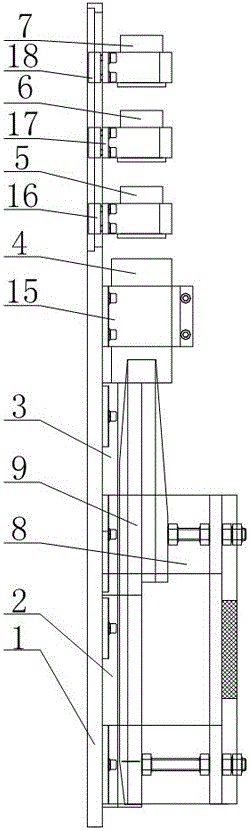

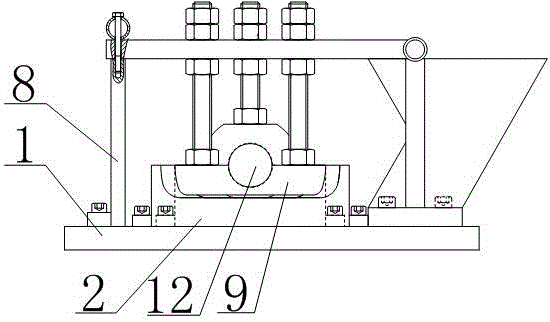

[0025] Such as Figures 1 to 6 As shown, a wrapping molding method for leaky cables of the present invention includes a longitudinal wrapping platform 1, on which a coaxial first longitudinal wrapping mold 2 and a second longitudinal wrapping mold 3 are sequentially installed, the first longitudinal wrapping mold 3 The mold cavity of the longitudinal wrapping mold and the second longitudinal wrapping mold 3 is connected into a streamlined mold cavity as a whole, and a mandrel support 8 is fixedly installed on the longitudinal wrapping platform 1, and the mandrel support 8 is positioned on the streamlined mold cavity. Directly above the cavity, a mandrel 9 is installed on the mandrel bracket 8. The mandrel 9 cooperates with the mold cavity to form a molding channel for the copper strip. The mandrel 9 is formed by connecting a conical plate 10 and a conical body 11. The conical body 11 A through hole 12 is provided on the axis of the conical plate 10 to form an inner layer feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com