Solid Insulated Cabinet Operating Mechanism

A solid insulation cabinet and operating mechanism technology, applied in the direction of contact drive mechanism, electrical components, electric switches, etc., can solve the problems of unreasonable space allocation, high equipment cost, and inability to disassemble the solid insulation cabinet, and achieve five defenses Perfect lock mechanism, reasonable space allocation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

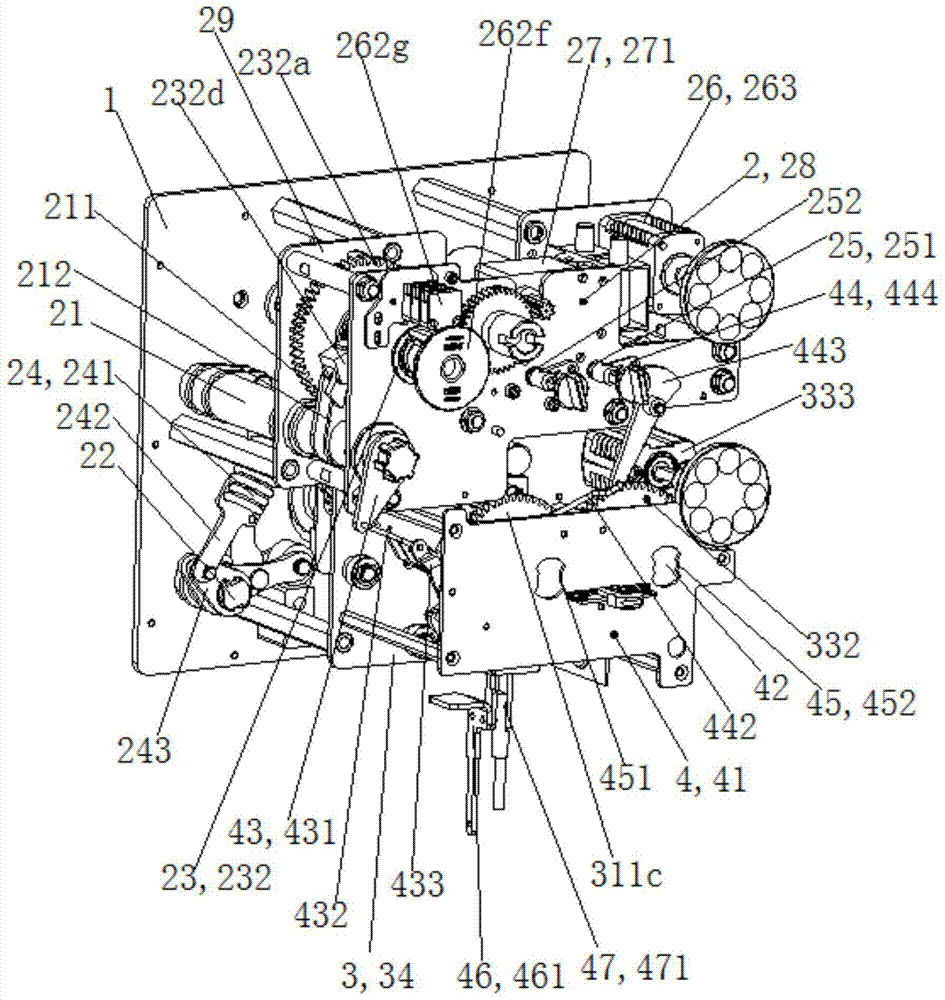

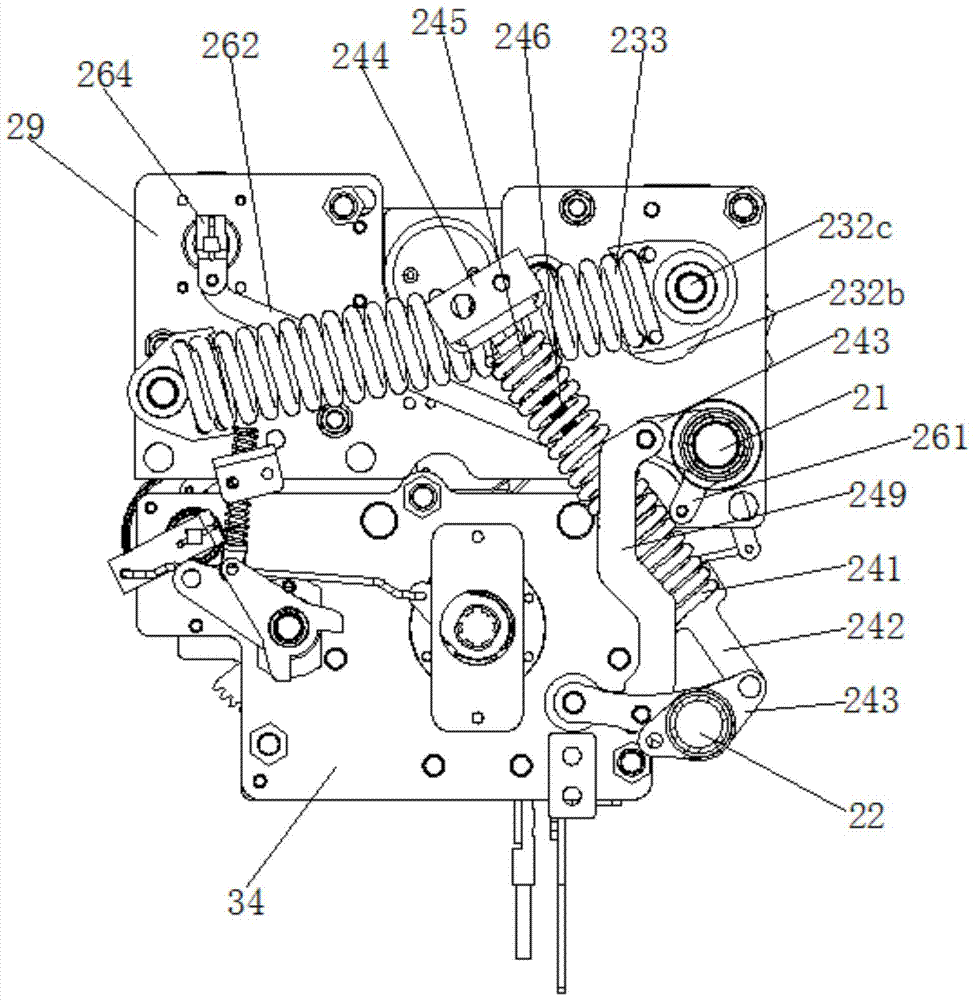

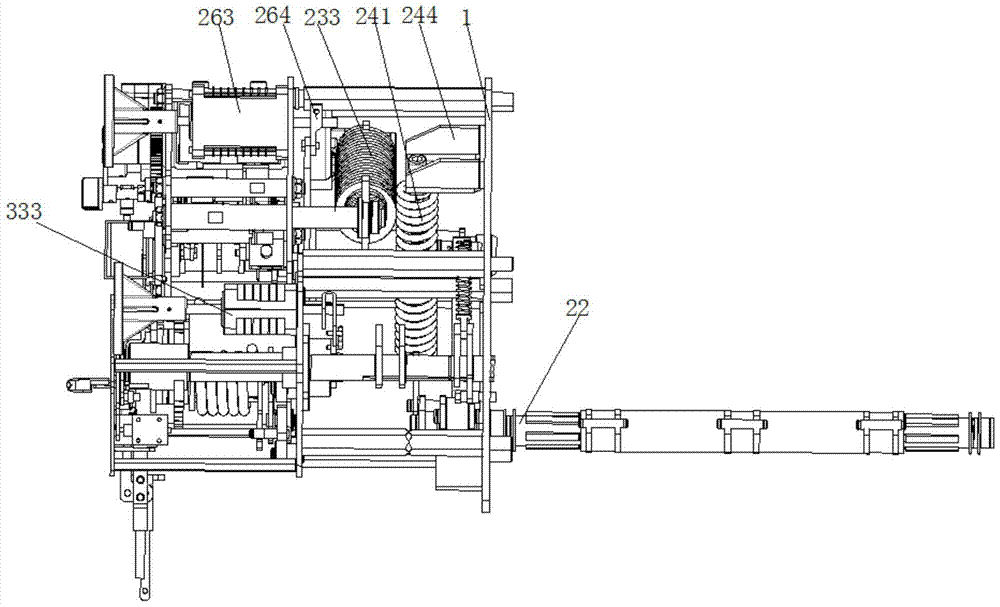

[0038] refer to Figure 1 to Figure 18 The operating mechanism of a solid insulation cabinet is shown, which includes an overall assembly plate 1, a circuit breaker module 2, a three-station module 3 and a five-proof interlock mechanism 4, and the circuit breaker module 2 includes a circuit breaker front assembly plate 28, a circuit breaker Rear assembly plate 29, circuit breaker operating shaft 21, circuit breaker main shaft 22, closing energy storage mechanism 23, opening energy storage mechanism 24 and closing and opening operating mechanism 25; three-station module 3 includes three-station module assembly plate 34 , an isolation operating mechanism 31 and a grounding operating mechanism 32; the five-proof interlock mechanism 4 includes a three-station module operating panel 41, an operating hole baffle 42, and a first link for interlocking between the operating hole baffle and the main shaft of the circuit breaker. The locking mechanism 43, the second interlocking mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com