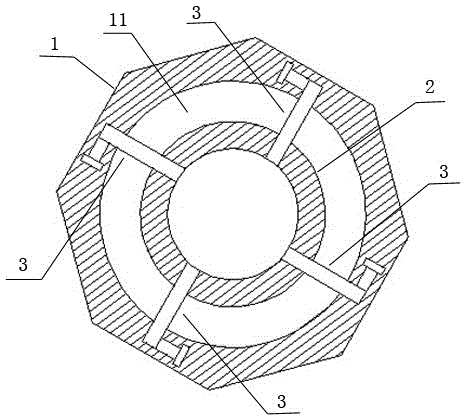

Movable installation structure of laser lens mounting base

A technology of movable installation and fixed seat, which is applied in the field of lasers, can solve the problems of low efficiency, disassembly and cleaning, inconvenient maintenance, cumbersome installation of fixed structures, etc., and achieve the effect of improved disassembly efficiency, simple and fast installation process, and stable connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

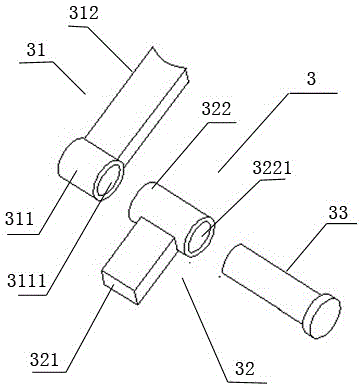

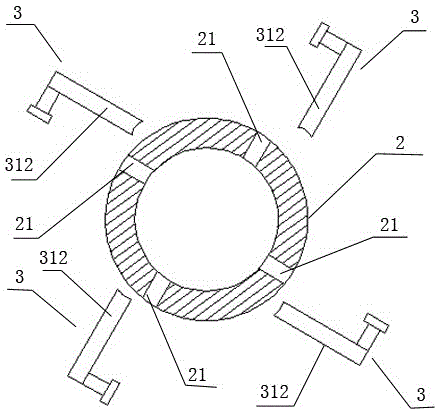

[0021] Such as image 3 As shown, the end of the limiting bar 312 is in a cylindrical structure, and the groove 21 is in a semicircular structure. The end of the cylindrical limiting bar 312 abuts in the semicircular groove 21 .

Embodiment 2

[0023] Such as Figure 4 As shown, the end of the limiting bar 312 is provided with an arc-shaped piece 3121, and the groove 21 is in an arc-shaped structure. The arc-shaped piece 3121 abuts in the arc-shaped groove 21 . The abutment method of the arc structure makes the clipping between the limiting bar 312 and the lens holder 2 more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com