Anti-cavitation restrictors for injector control valves

A technology for controlling valves and valve seats, which is applied in fuel injection control, engine control, fuel injection pumps, etc., and can solve problems such as reduction and bubble generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

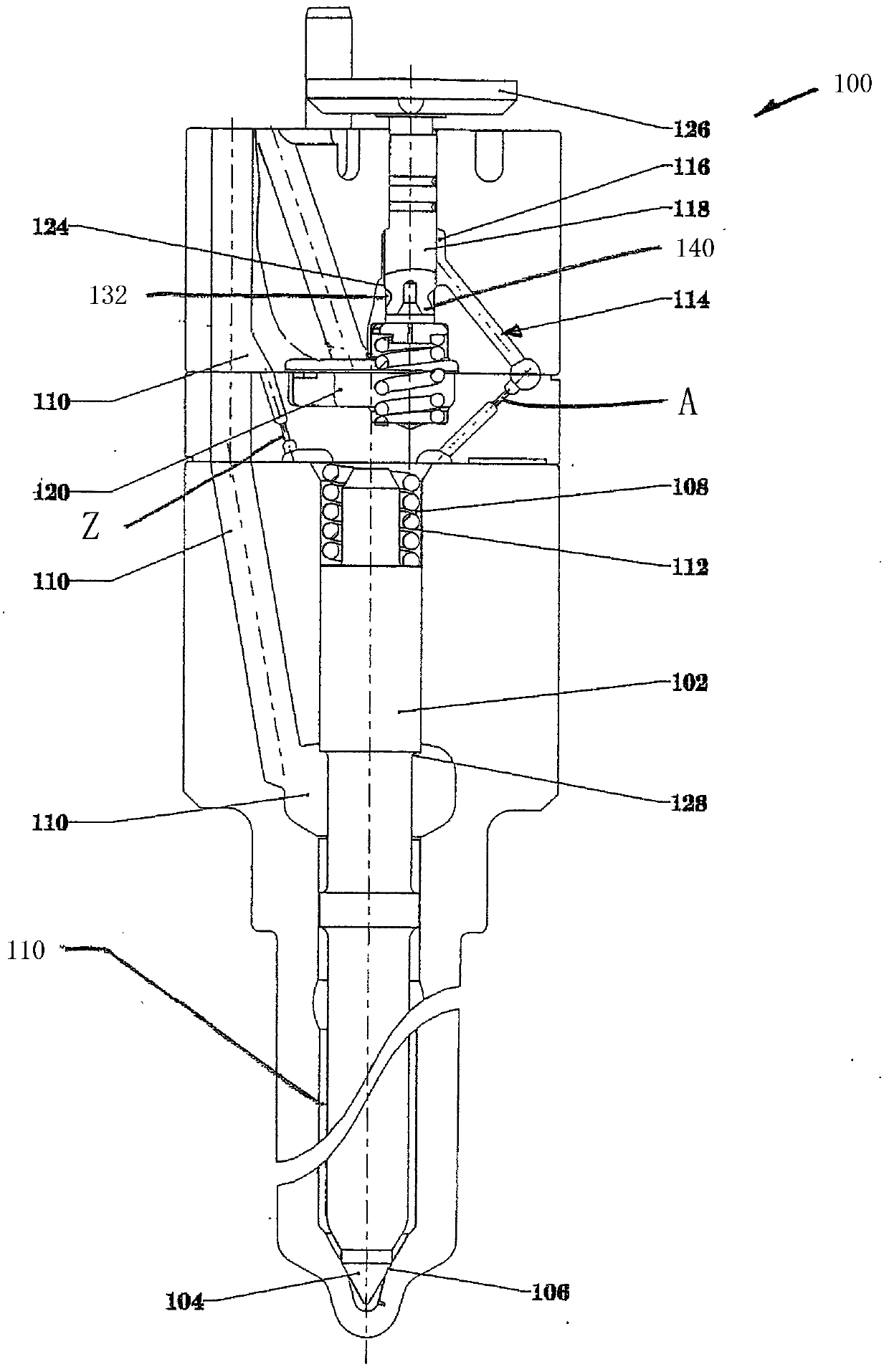

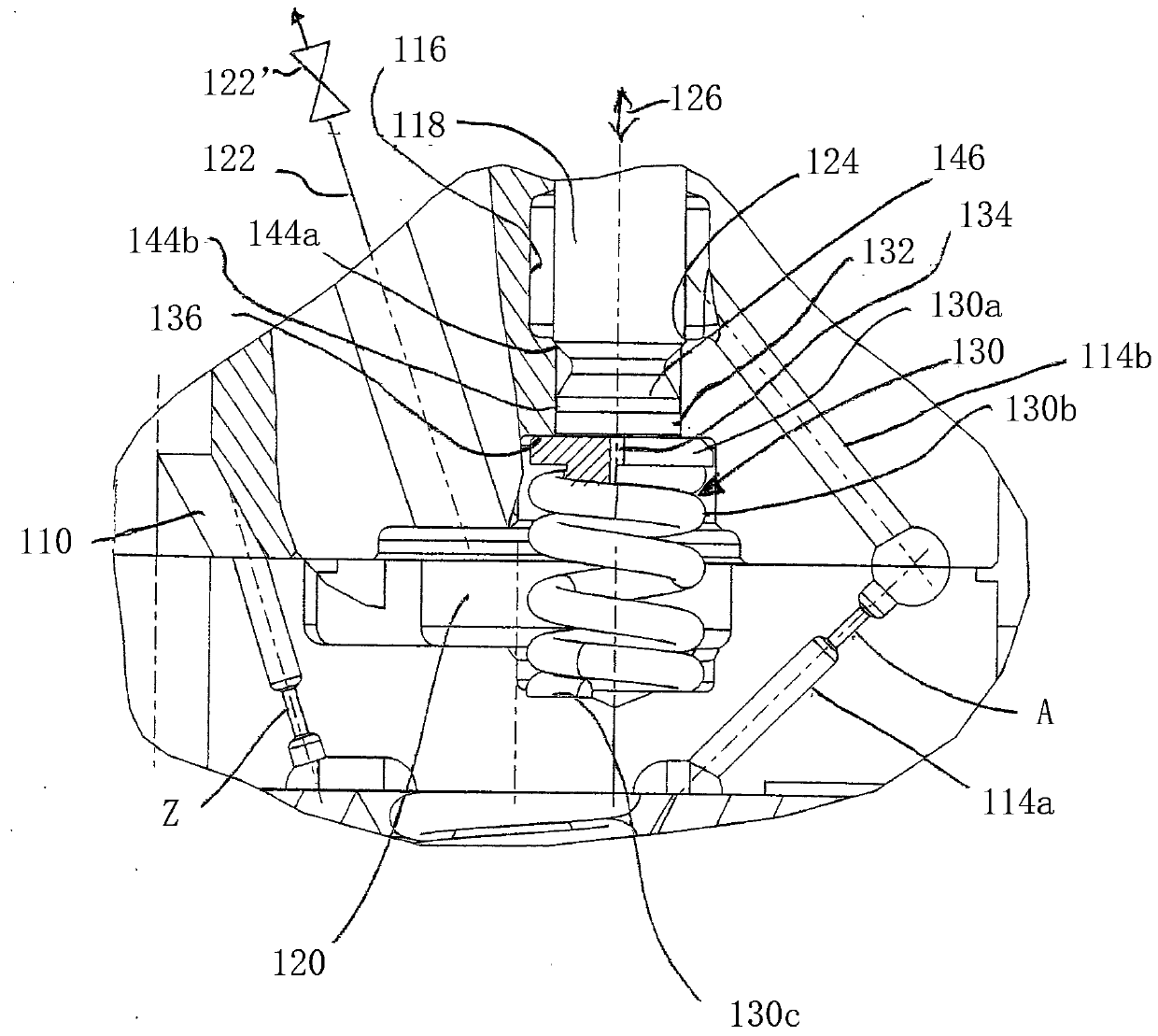

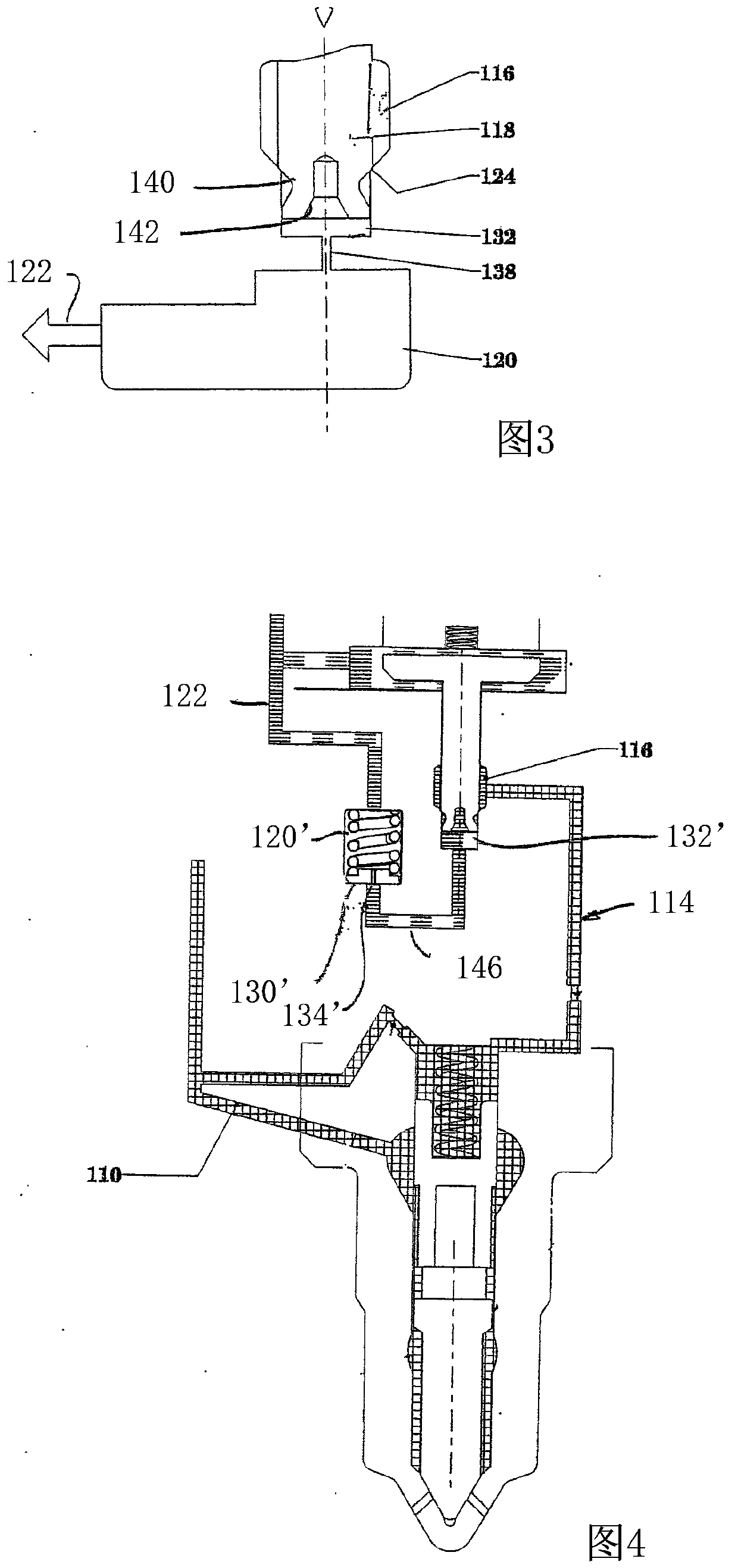

[0025] figure 1 with 2 An embodiment of the injector 100 having a needle valve 102 is shown. The needle valve 102 has a tip 104 that engages a seat 106 in the injector body under closed conditions during the injection event. In this closed condition, the needle control chamber 108 is supplied with high-pressure fuel 110 from a high-pressure feed pump (not shown), and similarly, the same high-pressure fuel 110 is supplied to the annular surface 128 at the middle position on the needle. . Due to the difference in area, the fluid pressure on the injection needle at the control chamber 108 is significantly higher than the fluid pressure at the upper end of the needle. Since this net downward fluid force is counteracted by the spring 112 in the chamber 108, the needle is maintained against the support 106.

[0026] The flow passages 114 a and b connect the high-pressure needle control chamber 108 and the control valve chamber 116. The control valve 118 has a shank pin with a general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com