Electric heating thermos bottle with safety structure

A safety structure and technology of boiling water bottles, applied in non-pressure containers, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve problems such as burns to users, reduction in mechanical strength and toughness, and potential safety hazards for users, and achieve extended The effect of service life, long service life and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

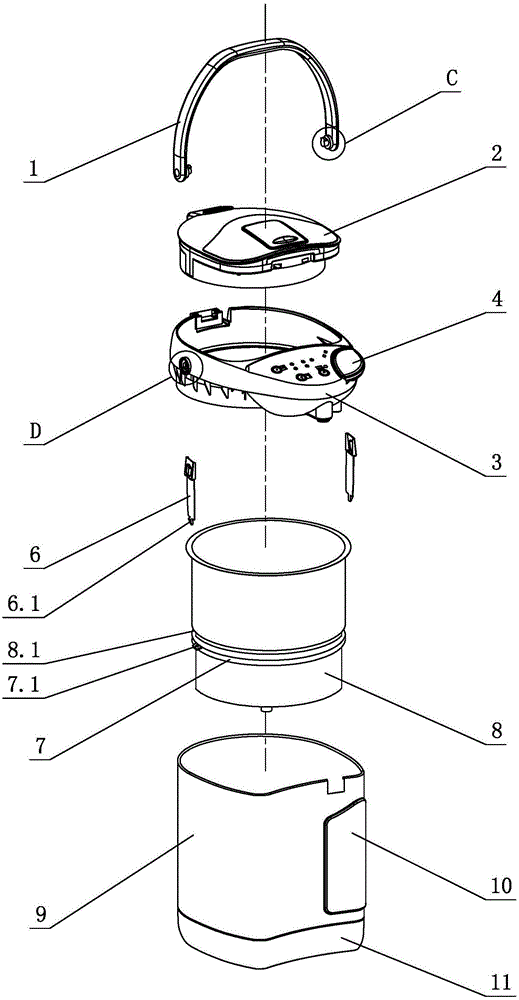

[0034] The shell 9 described in the present invention includes a plastic outer layer and a plastic inner layer, and a fireproof partition layer is filled between the plastic outer layer and the plastic inner layer, and the fireproof partition layer is composed of the following components in parts by weight: composition:

[0035]

Embodiment 2

[0037] The shell 9 described in the present invention includes a plastic outer layer and a plastic inner layer, and a fireproof partition layer is filled between the plastic outer layer and the plastic inner layer, and the fireproof partition layer is composed of the following components in parts by weight: composition:

[0038]

[0039]

Embodiment 3

[0041] The shell 9 described in the present invention includes a plastic outer layer and a plastic inner layer, and a fireproof partition layer is filled between the plastic outer layer and the plastic inner layer, and the fireproof partition layer is composed of the following components in parts by weight: composition:

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com