Capsule plate assembly

A capsule plate and capsule technology, applied in capsule delivery, drug delivery, pharmaceutical formulations, etc., can solve problems such as labor-intensive, low efficiency, and difficult to standardize operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

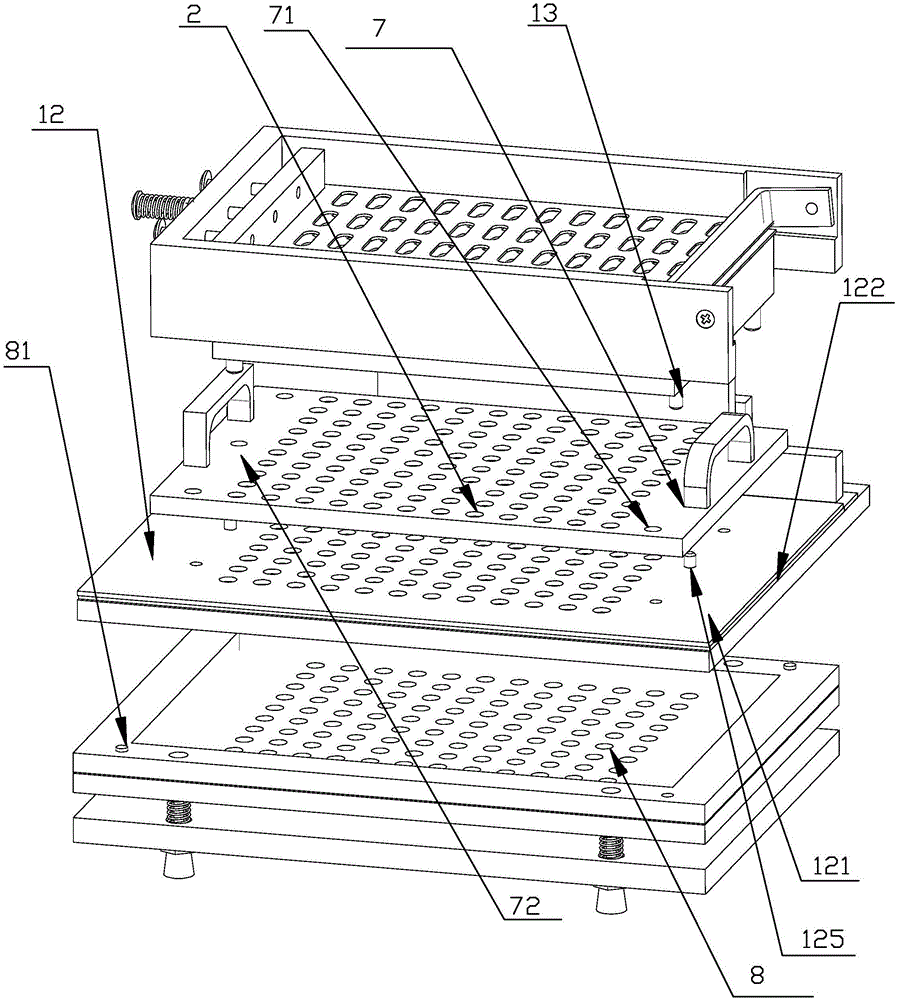

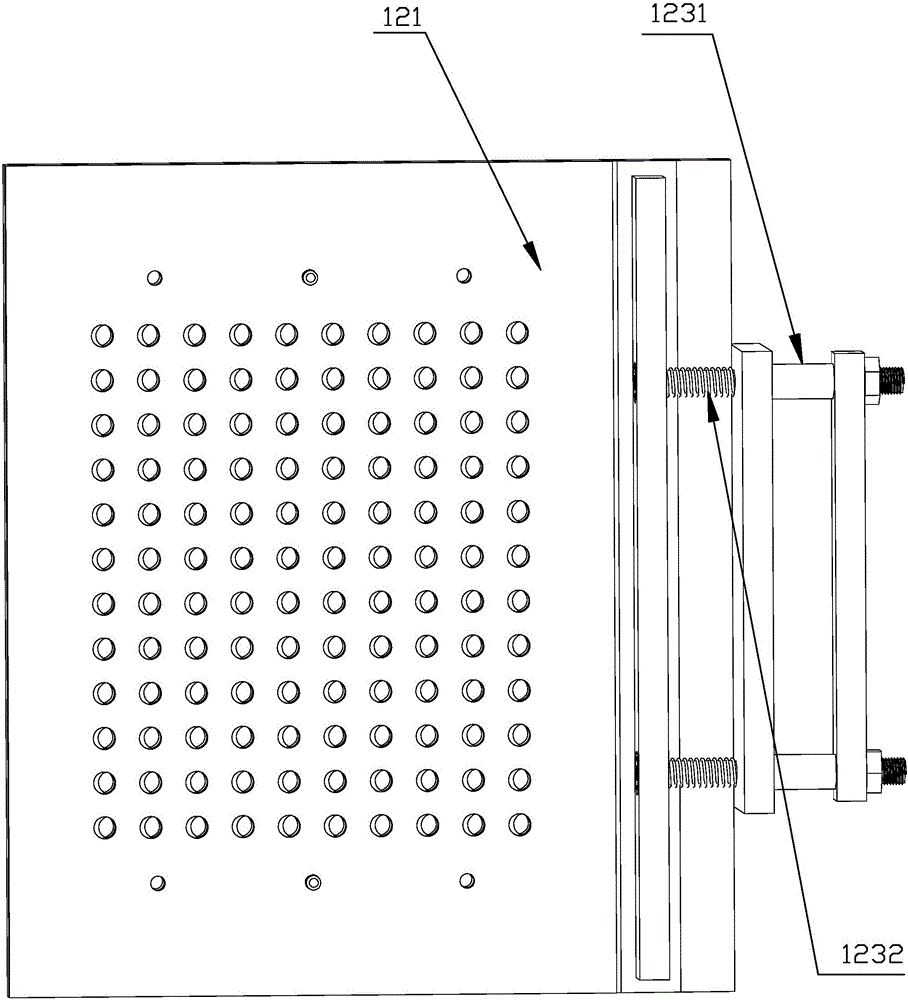

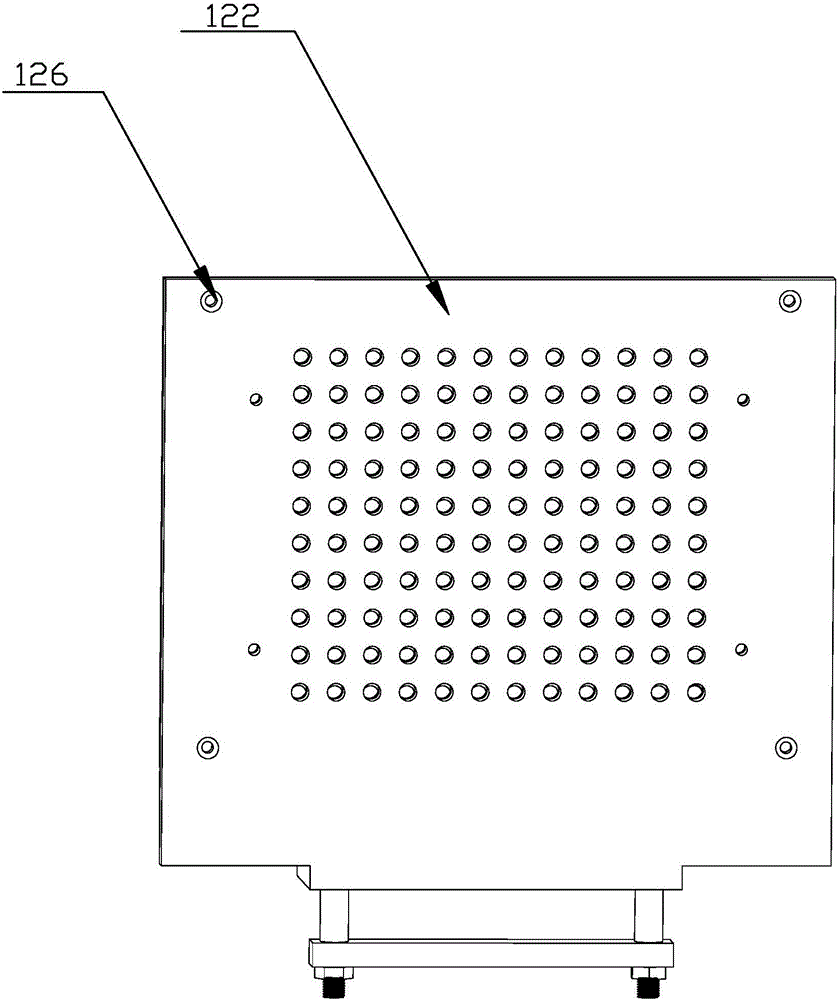

[0022] like figure 1 Figure 4 Figure 5As shown, the present invention includes a capsule arrangement mechanism, a separation plate 12, an intermediate plate 7, a body plate 8, a cap plate 9, a powder pressing plate 10, and a powder baffle plate 11. The same capsule cavity 2, the capsule cavity 2 includes a mouth 21 and a cavity 22 extending downward along the mouth, the shape and size of the mouth 21 can make the capsule fall into the cavity from the mouth, The capsule arranging mechanism includes a housing 1, the middle plate 7 abuts against the lower part of the housing 1, the capsule arranging mechanism is movably connected with the middle plate 7, and the capsule cavity 2 on the capsule arranging mechanism is connected to the middle plate 7. The positions of the capsule cavities 2 correspond one by one, the separation plate 12 abuts against the bottom of the middle plate 7, the separation plate 12 is movably connected with the middle plate 7, and the positions of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com