A hollow foam shaft and its processing technology

A foam and hollow technology, applied in sports accessories, gymnastics equipment, stilts, etc., can solve the problems of large differences in hardness of surface patterns, shorten the service life of foam shafts, and low utilization of raw materials, achieving short production cycles, low cost, and high utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

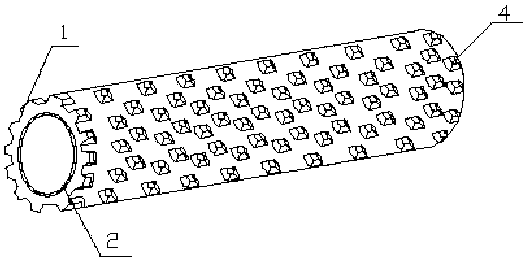

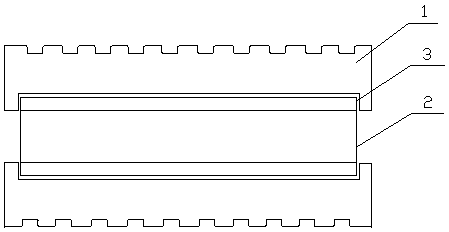

[0035] A hollow foam shaft described in this embodiment includes an outer cladding layer 1 and an inner lining layer 2, the outer cladding layer 1 is a hollow cylinder, a groove 3 is provided inside the outer cladding layer 1, and the inner lining layer 2 is arranged on In the groove 3, the surface of the outer cladding layer 1 is provided with staggered massage bumps 4, the massage bumps 4 are trapezoidal, the shape of the inner lining layer 2 is a hollow cylinder with two ends open, and the inner lining layer The wall thickness of 2 is identical with groove 3 depth.

[0036] The lining layer 2 described in this embodiment is an ABS pipe.

[0037] A method for processing a hollow foam shaft described in this embodiment comprises the following steps:

[0038] (1) Preparation of raw materials: its mass components are: ethylene-vinyl acetate copolymer: 75 parts, N,N′-dinitrosopentamethylenetetramine: 8 parts, urethane and 2-mercaptan Composition of 50% of benzothiazole: 15 par...

Embodiment 2

[0046]A hollow foam shaft described in this embodiment includes an outer cladding layer and an inner lining layer, the outer cladding layer is a hollow cylinder, a groove is provided inside the outer cladding layer, the inner lining layer is arranged in the groove, and the inner lining layer is arranged in the groove. The surface of the outer cladding layer is provided with interlaced massage bumps, the massage bumps are semicircular, the shape of the inner liner is a hollow cylinder with two ends open, and the wall thickness of the inner liner is the same as the depth of the groove.

[0047] The lining layer described in this embodiment is an EVA tube.

[0048] A method for processing a hollow foam shaft described in this embodiment comprises the following steps:

[0049] (1) Preparation of raw materials: its mass components are: ethylene-vinyl acetate copolymer: 70 parts, a composition of 50% of azodicarbonamide and sodium bicarbonate: 10 parts, sulfur monochloride: 12 parts...

Embodiment 3

[0057] A hollow foam shaft described in this embodiment includes an outer cladding layer and an inner lining layer, the outer cladding layer is a hollow cylinder, a groove is provided inside the outer cladding layer, the inner lining layer is arranged in the groove, and the inner lining layer is arranged in the groove. The surface of the outer cladding layer is provided with staggered massage bumps, the massage bumps are in the shape of a wolf tooth, the shape of the inner lining layer is a hollow cylinder with both ends open, and the wall thickness of the inner lining layer is the same as the depth of the groove.

[0058] The lining layer described in this embodiment is an EVA tube.

[0059] A method for processing a hollow foam shaft described in this embodiment comprises the following steps:

[0060] (1) Prepare raw materials: the mass components are: ethylene-vinyl acetate copolymer: 80 parts, 4,4′-oxybisbenzenesulfonyl hydrazide: 5 parts, tetramethylthiuram disulfide: 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com