Reciprocating type sand screening machine

A sand sifting machine, reciprocating technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of many transition devices, easy damage to the machine, loose structure, etc., to achieve the effect of compact overall structure and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

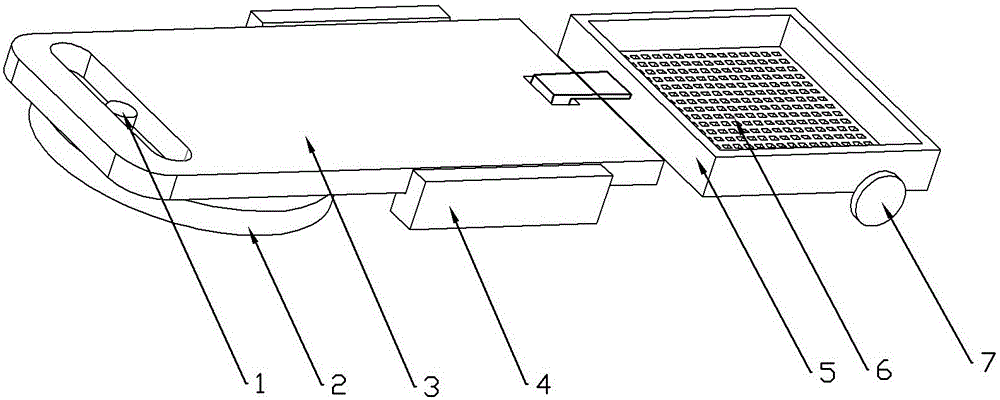

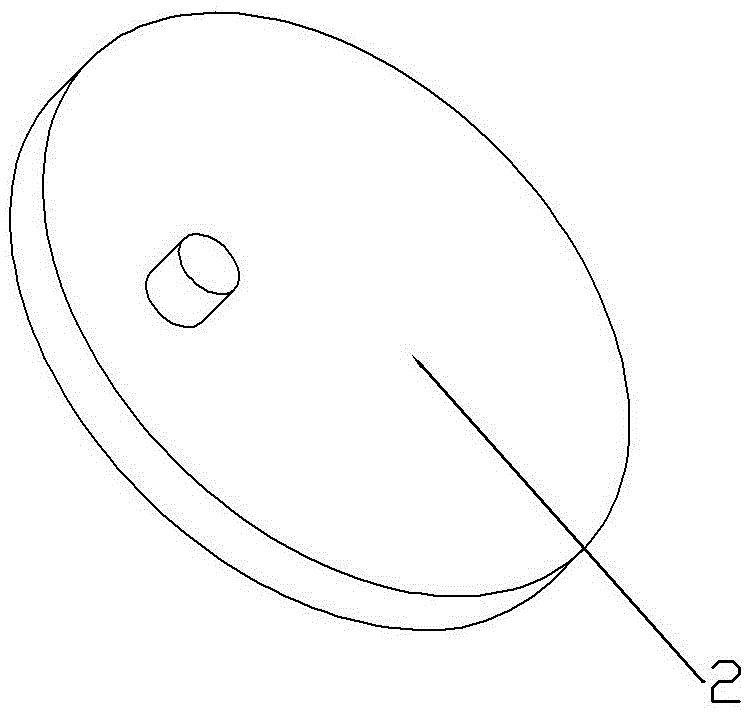

[0013] The reference signs in the accompanying drawings of the description include: round pin 1, turntable 2, connecting plate 3, guide rail 4, baffle plate 5, sand net 6, wheel 7.

[0014] The embodiment is basically as attached figure 1 Shown:

[0015] The reciprocating sand screening machine includes a turntable 2, a connecting plate, a guide rail 4 and a sand net 6 slidingly matched with the connecting plate. The turntable 2 is driven by the motor, combined with figure 2 As shown, a round pin 1 is provided at the eccentric part of the end face of the turntable 2, and one end of the connecting plate is movably connected with the sand net 6, and the other end is provided with a long groove, which is perpendicular to the moving direction of the connecting plate, and the long groove, connecting The plate 3 and the disk are on a central axis.

[0016] The connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com