Reducing sizing mill with short roller body, four upright posts and no house for bars

A technology of reducing and sizing mills without archway, which is applied in the direction of rolls, metal rolling stands, and metal rolling mill stands, and can solve problems such as high manufacturing and maintenance costs, unsuitable for reducing and sizing processes, and complex transmission system structures. , to achieve the effects of shortening the renovation period, saving renovation costs and improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

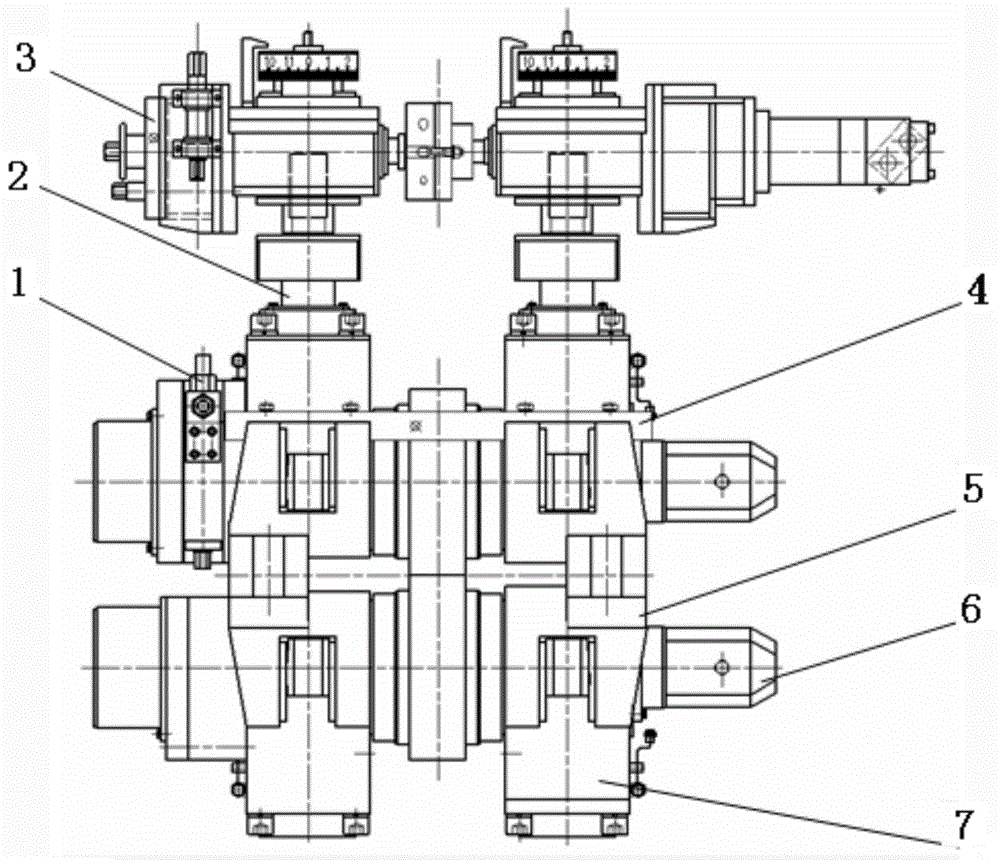

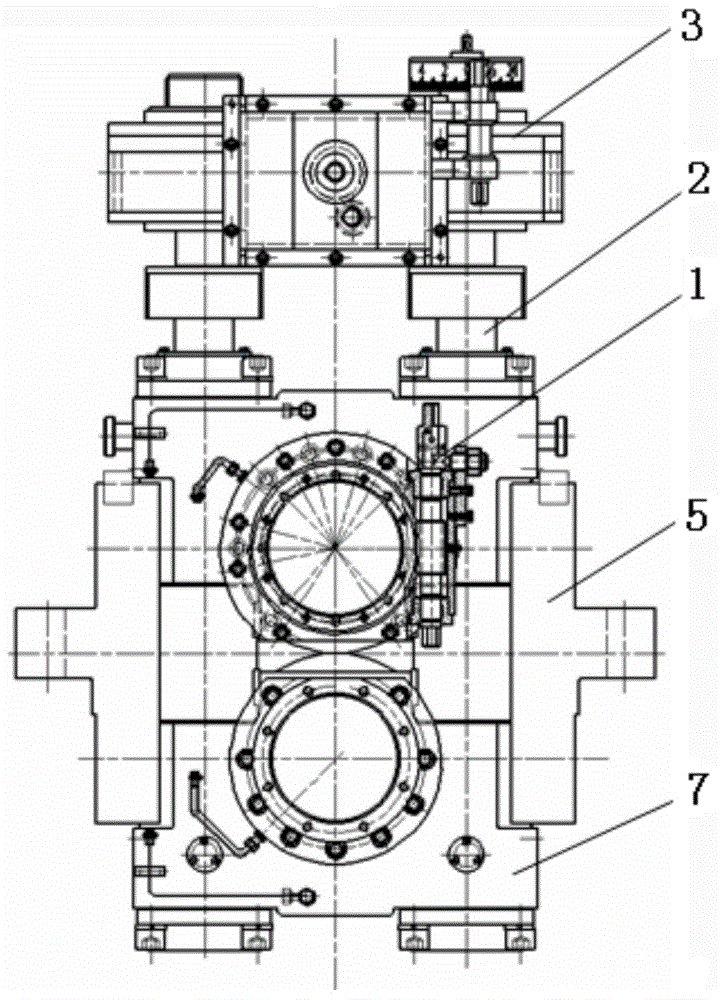

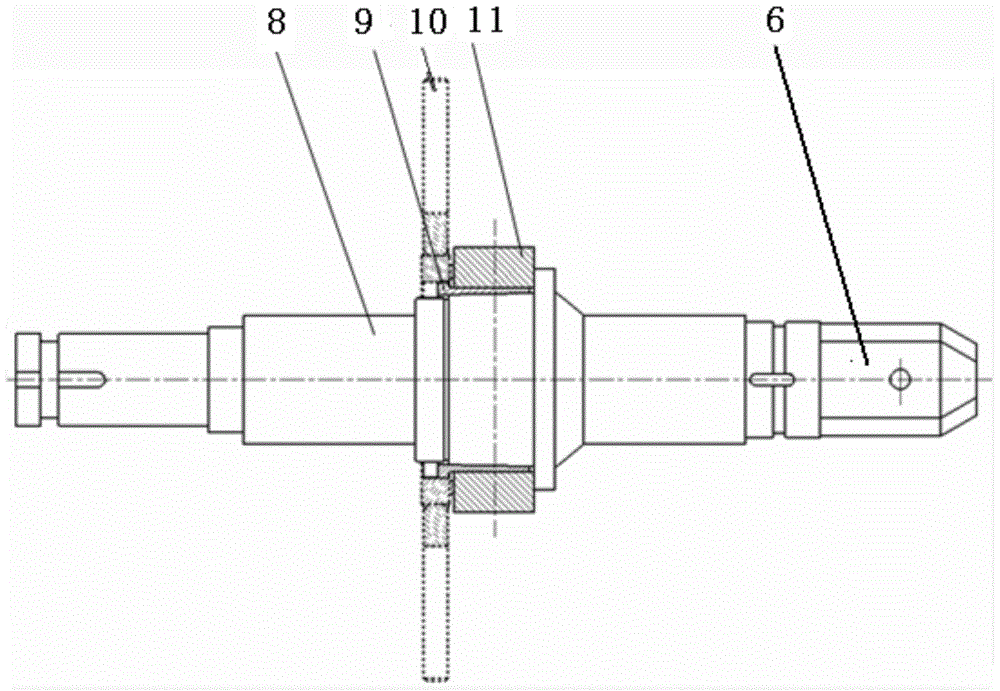

[0010] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings: Figure 1 ~ Figure 2 It is a front view and left view of the structure of a short-roll body four-column without archway bar reduction and sizing machine. image 3 It is a structural diagram of the short roll body roll 6 in the embodiment of the present invention; the frame of the reducing and sizing machine is a four-column structure without archway, and the roll 6 is a short roll body; the reducing and sizing machine is composed of an axial adjustment device 1, a column 2 , pressing device 3, connecting rod 4, support seat 5, short roll body roll 6, bearing seat 7, roll shaft 8, taper sleeve 9, handle 10, roll ring 11; the material of roll shaft 8 is alloy forged steel; The material of the roll ring 11 is hard alloy; when the combined roll is disassembled, the outer end of the taper sleeve 9 is matched with a handle 10 threaded therewith; the short ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com