Forging equipment with high forging uniformity

A technology of uniformity and equipment, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of difficulty in the synchronization of the four hammering units, and the inability to guarantee the uniformity of forging. Simple, high synchronicity, improved balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

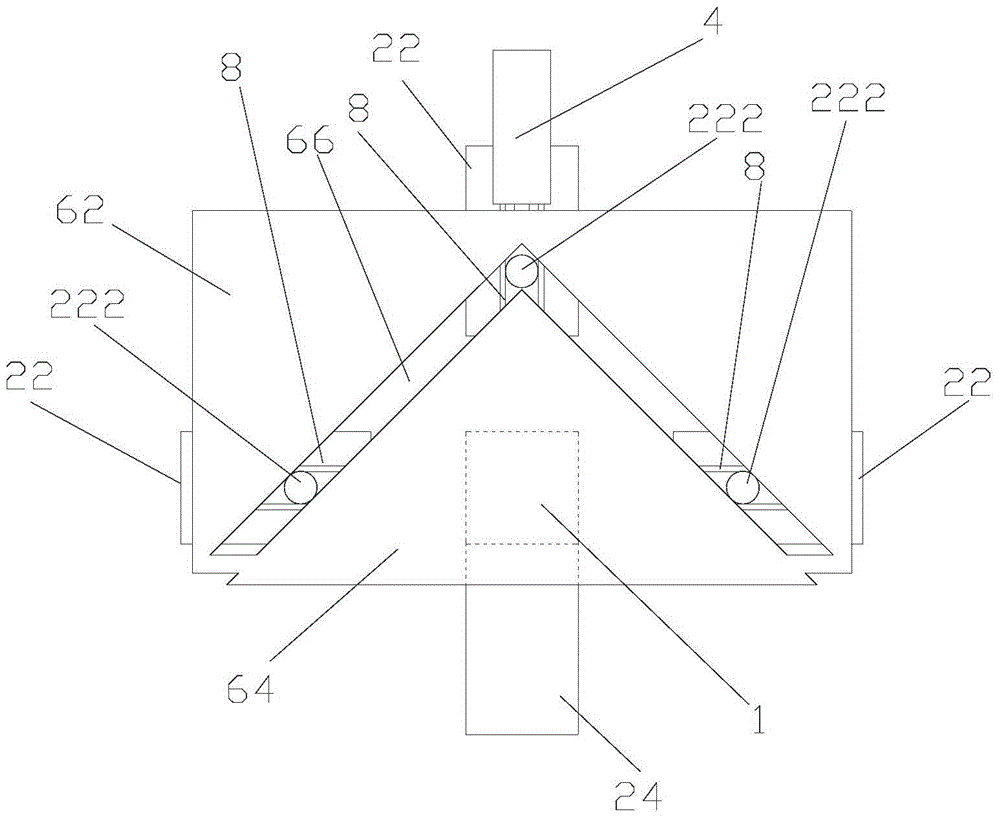

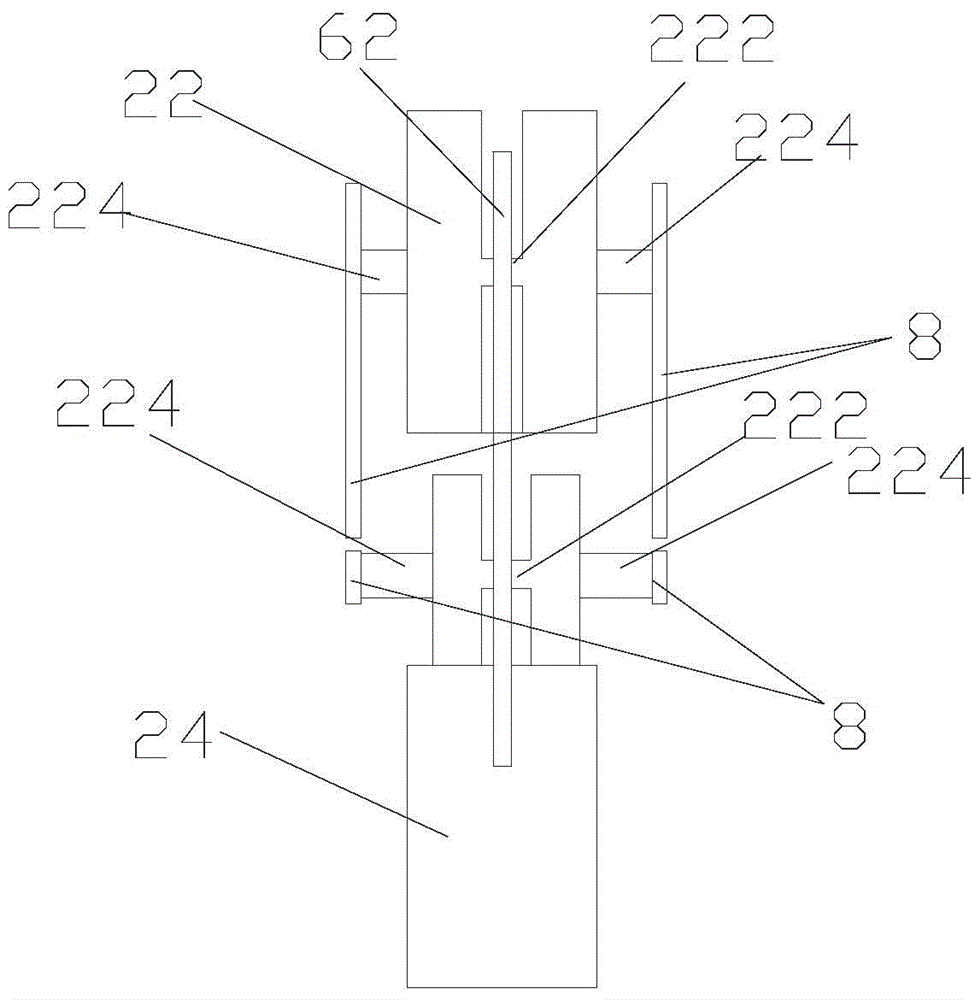

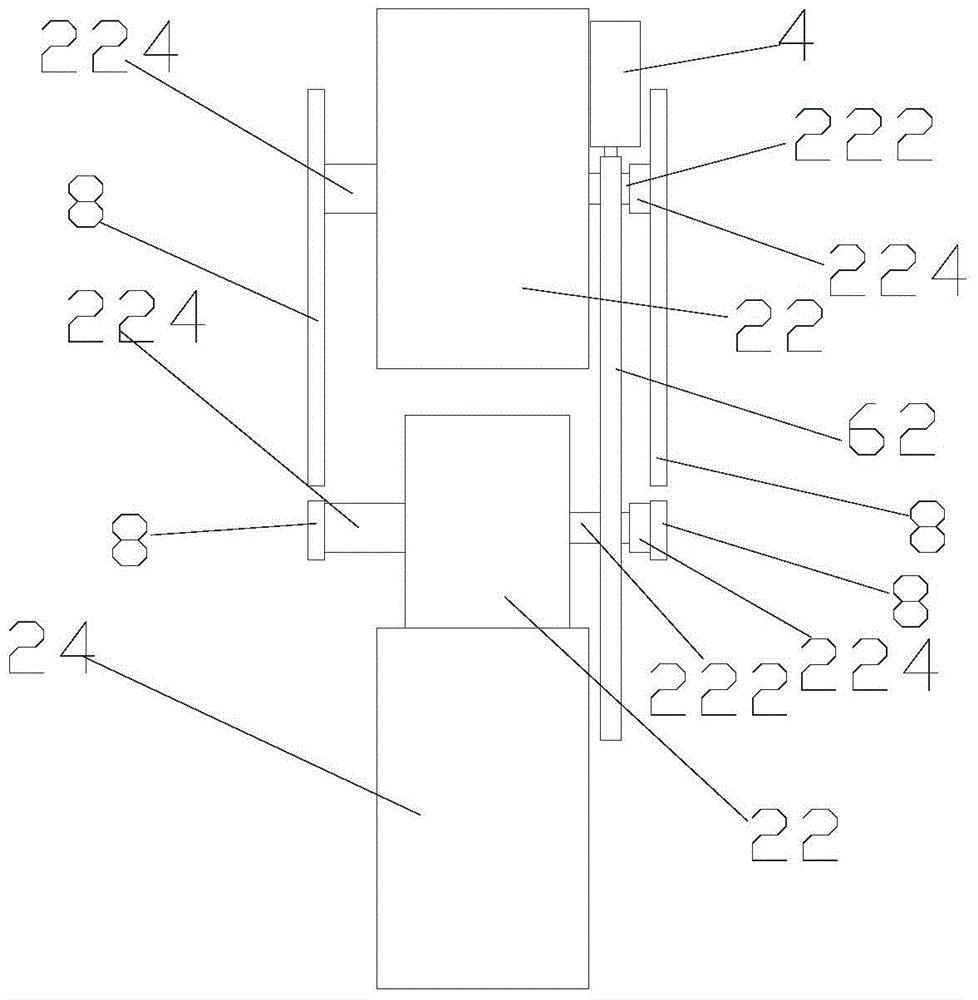

[0021] see Figure 1-2 , a forging equipment with high forging uniformity, including three movable hammering units 22 and one fixed hammering unit 24 distributed in a cross shape, and a driving device 4 for driving each movable hammering unit 22 to move toward the center or outward, Also included are transmissions connecting the drive 4 and the movable hammer unit 22 . The movable hammering unit 22 includes a slider 222, and the transmission device includes two pushers 62, 64 arranged at intervals. The two pushers 62, 64 are block-shaped, forming a gap 66 at a 90° angle between them, and the three sliders 222 can just fit into the gap 66 and one is located at the corner, and the other two are located on both sides of the gap 66. The three movable hammering units 22 are also respectively connected to the limit device, and the driving device 4 can drive the transmission device along the direction of the angle bisector of the corner. reciprocating movement.

[0022] Specificall...

Embodiment 2

[0028] Such as figure 1 , 3 As shown, a forging equipment with high forging uniformity is different from Embodiment 1 in that the slider 222 is located on one side of the movable hammering unit 22 and inside the corresponding guide block 224 . Since the slider 222 is arranged on the outside of the movable hammer unit 22, the movable hammer unit 22 can be kept in a complete block shape, which is more favorable for hitting and less likely to be damaged.

[0029] The working principle of the present invention is as follows:

[0030] The driving device 4 drives the transmission device downward, and the upper end pusher 62 of the transmission device touches the slider 222 downwards at three corresponding positions respectively, and pushes it downwards, so that the three movable hammering units 22 are restricted by the guide rail 8 All move towards the middle and approach the workpiece 1 until they are hammered on the workpiece 1; conversely, the driving device 4 drives the transm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap