Serpentine runner movable template group hole electrolytic processing device and processing method

A technology of movable template and processing device, applied in electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unguaranteed processing uniformity and poor processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Figure 4 The workpiece 20 and the mask cathode 18 are shown fixed to the clamp body by positioning pins.

[0020] 2. figure 2 The clamp shown is the lower clamp 22, which is clamped and fixed with the symmetrical upper clamp 17 by the air cylinder.

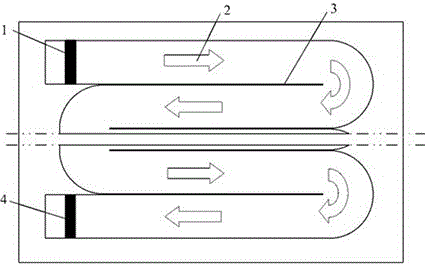

[0021] 3. figure 2 The shown liquid inlet 1 is connected with the liquid inlet pipe, and the liquid outlet 4 is connected with the liquid outlet pipe.

[0022] 4. The workpiece anode 20 is connected to positive electricity, and the mask plate cathode 18 is connected to negative electricity.

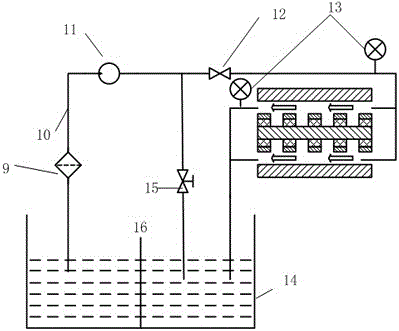

[0023] 5. Open the ball valve 15 and gate valve 12 of the electrolyte circulation system, open the multistage centrifugal pump 11, and adjust the pressure by observing the pressure gauge 14 and rotating the ball valve 15.

[0024] 6. Adjust the power supply parameters.

[0025] 7. Turn on the power supply 23 to perform electrolytic machining of group holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com