Electrochemical machining process and electrochemical machining device

An electrochemical processing and process technology, applied in the field of semiconductor technology, can solve problems such as easy uniformity, poor polishing uniformity, difficult stable control, etc., and achieve the effect of improving processing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

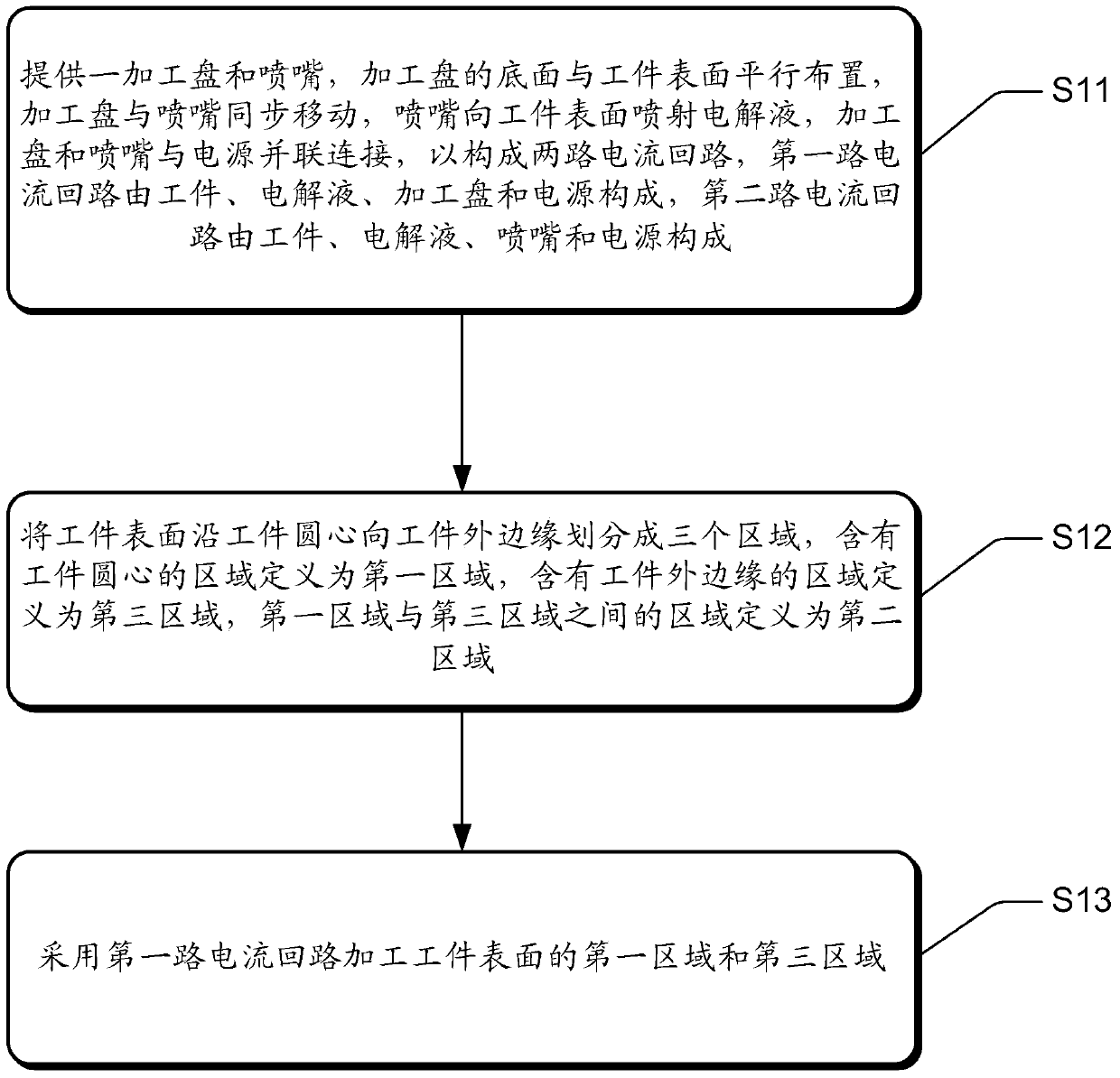

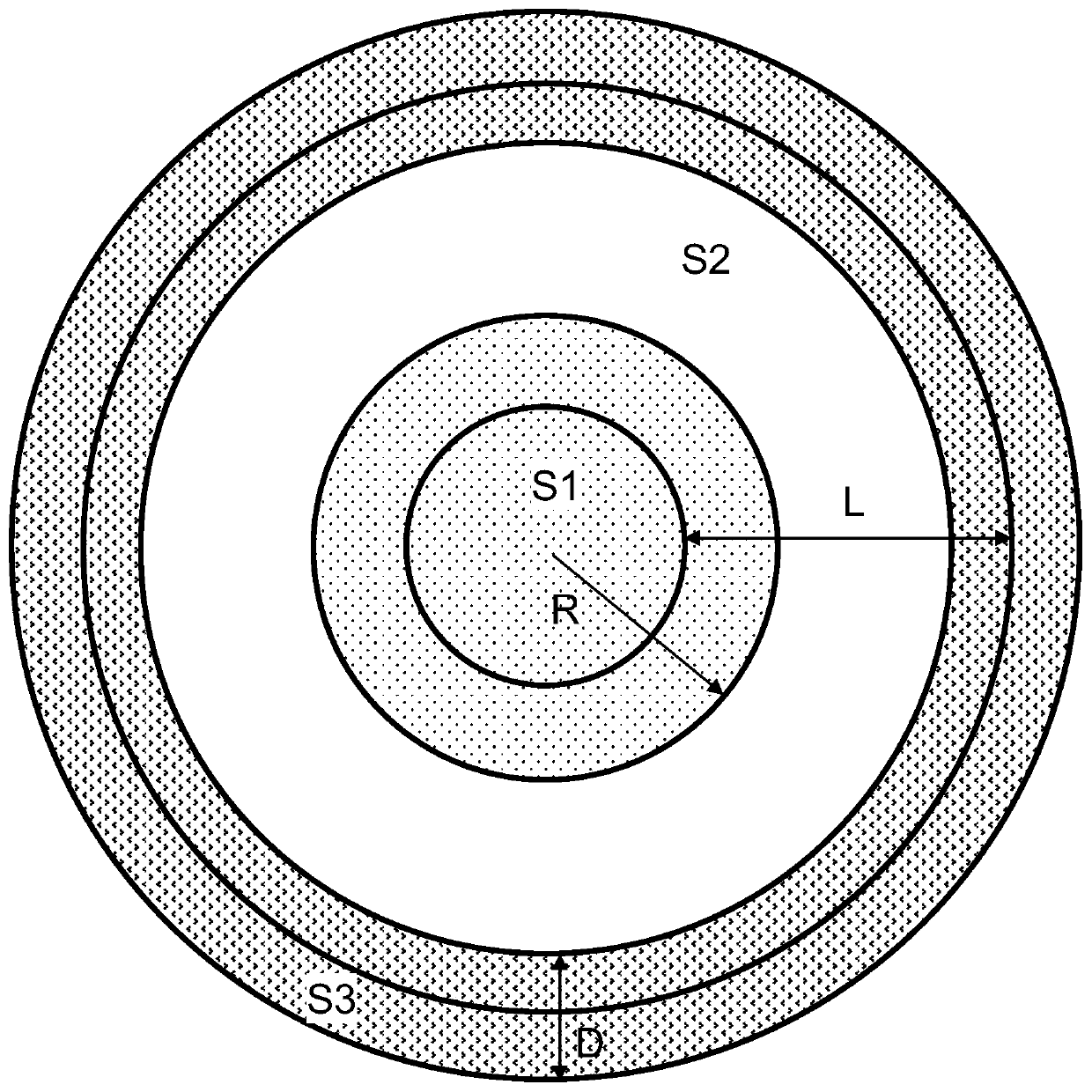

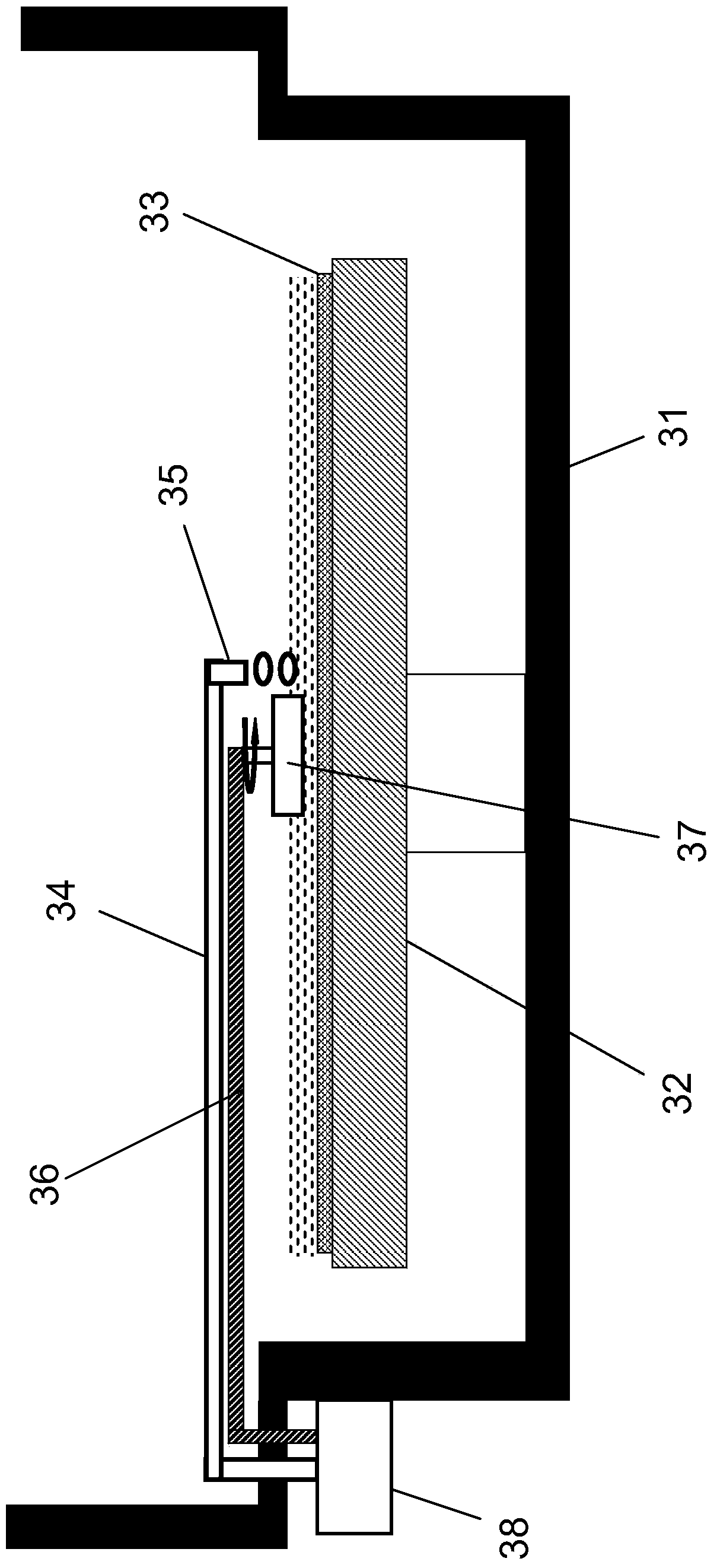

[0027] The main concept of the electrochemical processing technology proposed by the present invention is: a processing disc and a nozzle are provided, the processing disc is made of conductive material, the bottom surface of the processing disc is arranged parallel to the surface of the workpiece, the processing disc and the nozzle move synchronously, and the nozzle moves Electrolyte is sprayed on the surface. The electrochemical machining process of the present invention includes two current loops, one current loop is composed of workpiece, electrolyte, processing disk and power supply, and the other current loop is composed of workpiece, electrolyte, nozzle and power supply, and the two current loops can be switched , when processing different areas on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com