Method for characterizing processing uniformity of Bi-series high-temperature superconducting wire or strip

A high-temperature superconducting and uniformity technology, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the limited testing method for processing uniformity of Bi-based high-temperature superconducting wires or strips To improve the overall current-carrying performance, sampling spoon, and improve the uniformity of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment includes the following steps:

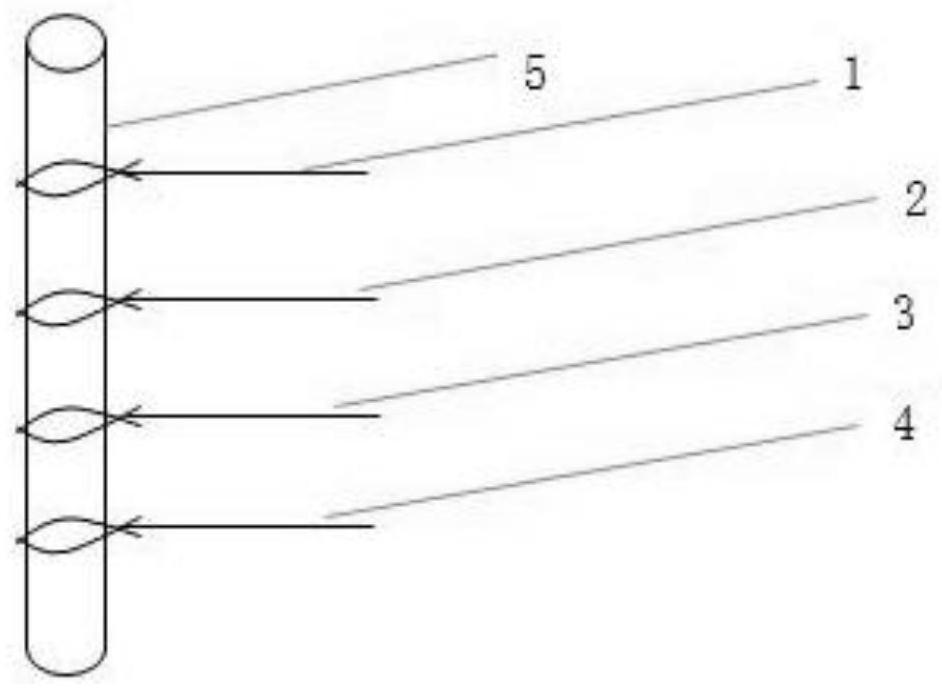

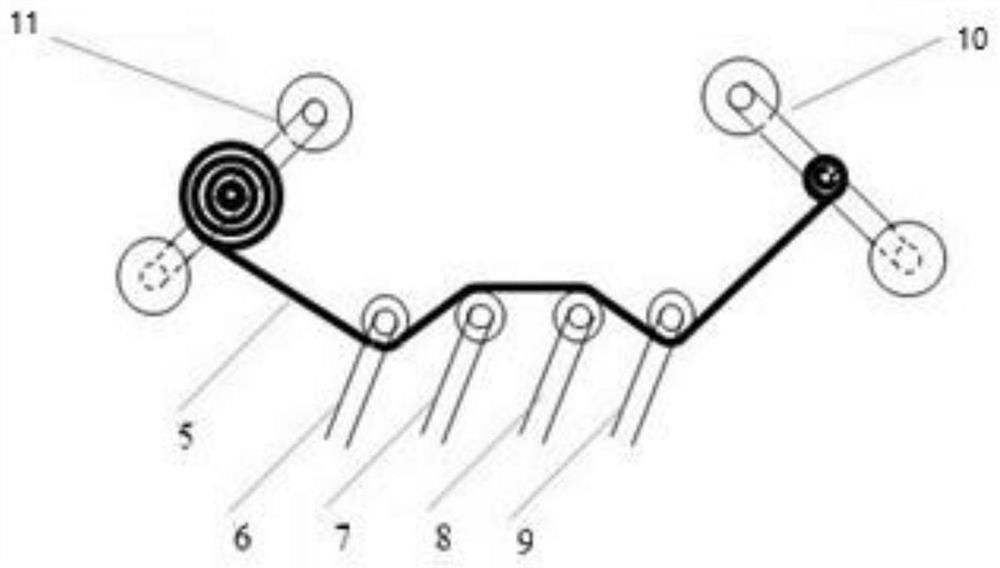

[0047] Step 1: Cut a sample with a length of 100 cm from the head end of the primary wire (10 m in length) during the processing of the Bi2212 high-temperature superconducting wire as the profile 5, and then the first wire 1, the second wire 2, the third wire 3 and The fourth wire 4 is wound and fixed on the profile 5 in turn, and the fixed position of the first wire 1, the second wire 2, the third wire 3 and the fourth wire 4 on the profile 5 is defined as the first position (the head end of the profile 5 within the range of 0 to 20 cm), and determine the distance L between the fixed point of the second wire 2 on the profile 5 and the fixed point of the third wire 3 on the profile 5 to be 10.0 cm; the first wire 1, the second wire The material of the second wire 2, the third wire 3 and the fourth wire 4 is copper;

[0048] Step 2, load the current I through the first wire 1 and the fourth wire 4 and form a loop with the ...

Embodiment 2

[0052] This embodiment includes the following steps:

[0053] Step 1. Cut a sample with a length of 60 cm from the head end of the secondary wire (6m in length) during the processing of the Bi2212 high temperature superconducting wire as the profile 5, and then place the first wire 1, the second wire 2, and the third wire 3 and the fourth wire 4 are wound and fixed on the profile 5 in turn, and the fixed position of the first wire 1, the second wire 2, the third wire 3 and the fourth wire 4 on the profile 5 is defined as the first position (the head of the profile 5 end within the range of 0-20cm), and determine that the distance L between the fixed point of the second wire 2 on the profile 5 and the fixed point of the third wire 3 on the profile 5 is 10.0cm; the first wire 1, The materials of the second wire 2, the third wire 3 and the fourth wire 4 are all copper;

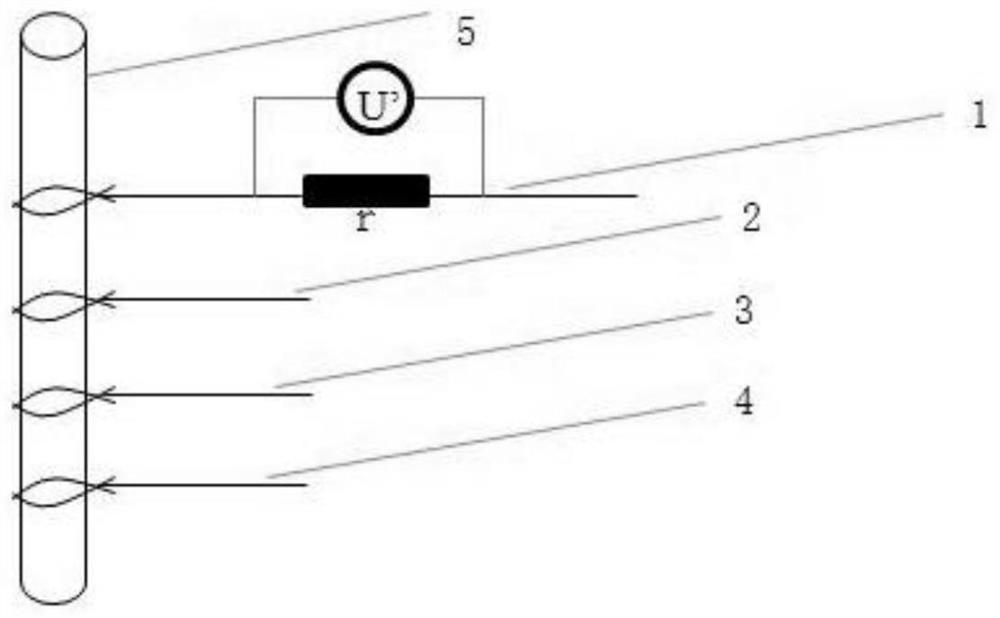

[0054] Step 2, add a voltage dividing resistor with a resistance value r=0.001Ω in the first copper wire 1, t...

Embodiment 3

[0059] This embodiment includes the following steps:

[0060] Step 1, in the processing process of the Bi2212 high temperature superconducting wire rod, the head end and the tail end of the third wire rod (14m in length) are respectively intercepted as samples with a length of 20cm as the profile 5, and then the first wire 1, the second wire 2, the second wire The three wires 3 and the fourth wire 4 are wound and fixed on the profile 5 in turn, and the fixed positions of the first wire 1, the second wire 2, the third wire 3 and the fourth wire 4 on the profile 5 are determined as the first position (three times) The length of the head end of the wire is 20cm), and the distance L between the fixed point of the second wire 2 on the profile 5 and the fixed point of the third wire 3 on the profile 5 is 10.0cm; the first wire 1 , the materials of the second wire 2, the third wire 3 and the fourth wire 4 are all copper;

[0061] Step 2, load the current I through the first wire 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com