Plasma treatment equipment and its electrostatic chuck

An electrostatic chuck and plasma technology, which is applied to circuits, discharge tubes, electrical components, etc., can solve the problem that the second insulating layer, the first insulating layer and the wafer cannot be rapidly heated up, and achieves simple structure and low cost. Low, easy-to-populate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

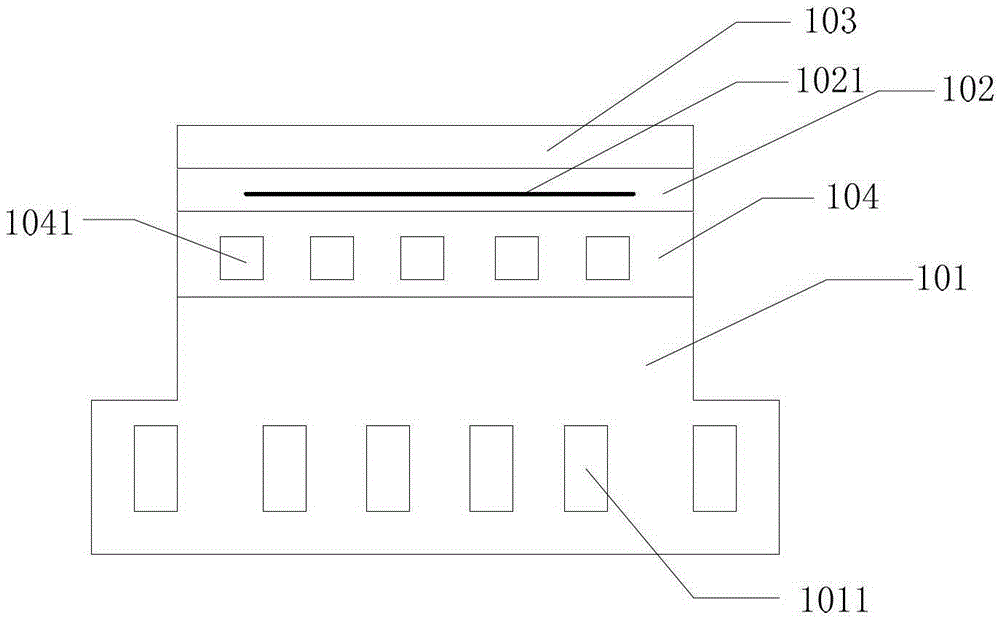

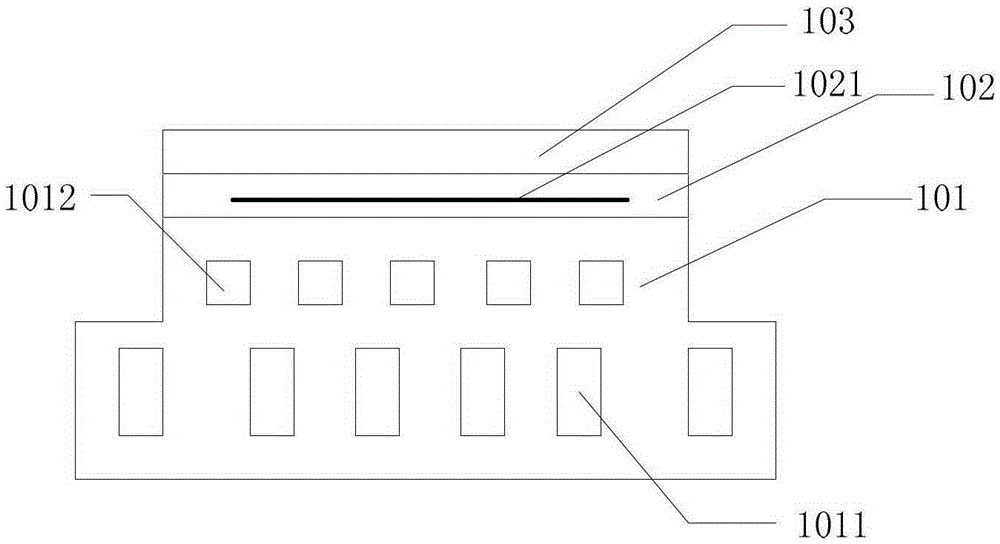

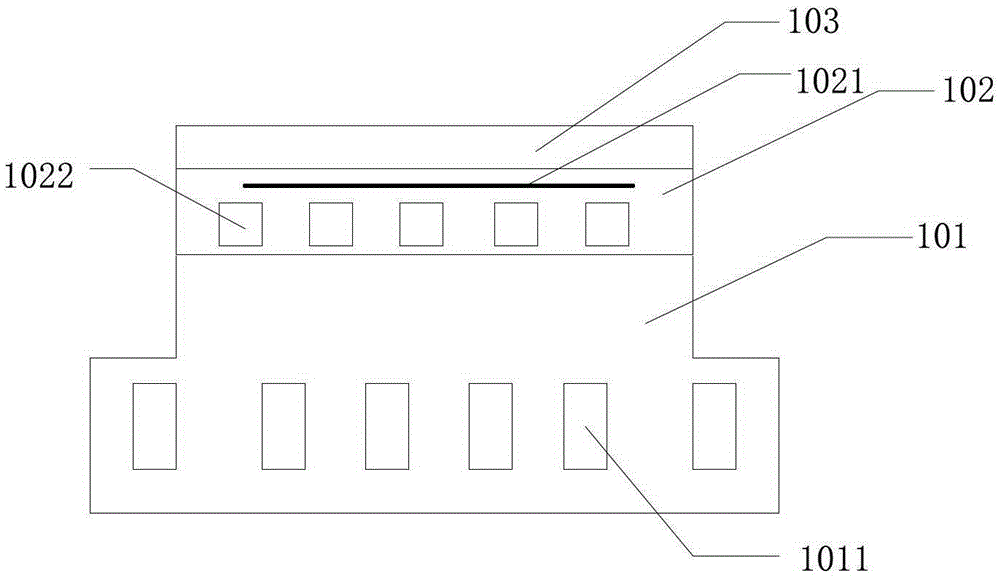

[0019] Such as figure 1 As shown, the first embodiment of the present invention provides an electrostatic chuck, which includes the following parts: a base 101 , a heat insulating layer 104 , a second insulating layer 102 and a first insulating layer 103 , which are layered from bottom to top.

[0020] Specifically, the base body 101 is the bottom of the electrostatic chuck, used to support other parts, and a plurality of coolant flow channels 1011 are arranged inside, used to inject coolant to cool the entire electrostatic chuck; the heat insulation layer 104 serves as a heat insulation unit It is arranged above the base 101 to isolate the heat conduction between the second insulating layer 102 and the base 101; the second insulating layer 102 is arranged above the heat insulating layer 104, and a heater 1021 is arranged inside it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com