Electrochemical method and electrochemical device

An electrochemical and positive technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of the limitation of the plating tank, the unsatisfactory uniformity of the electroplated metal layer, and the increase of the process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

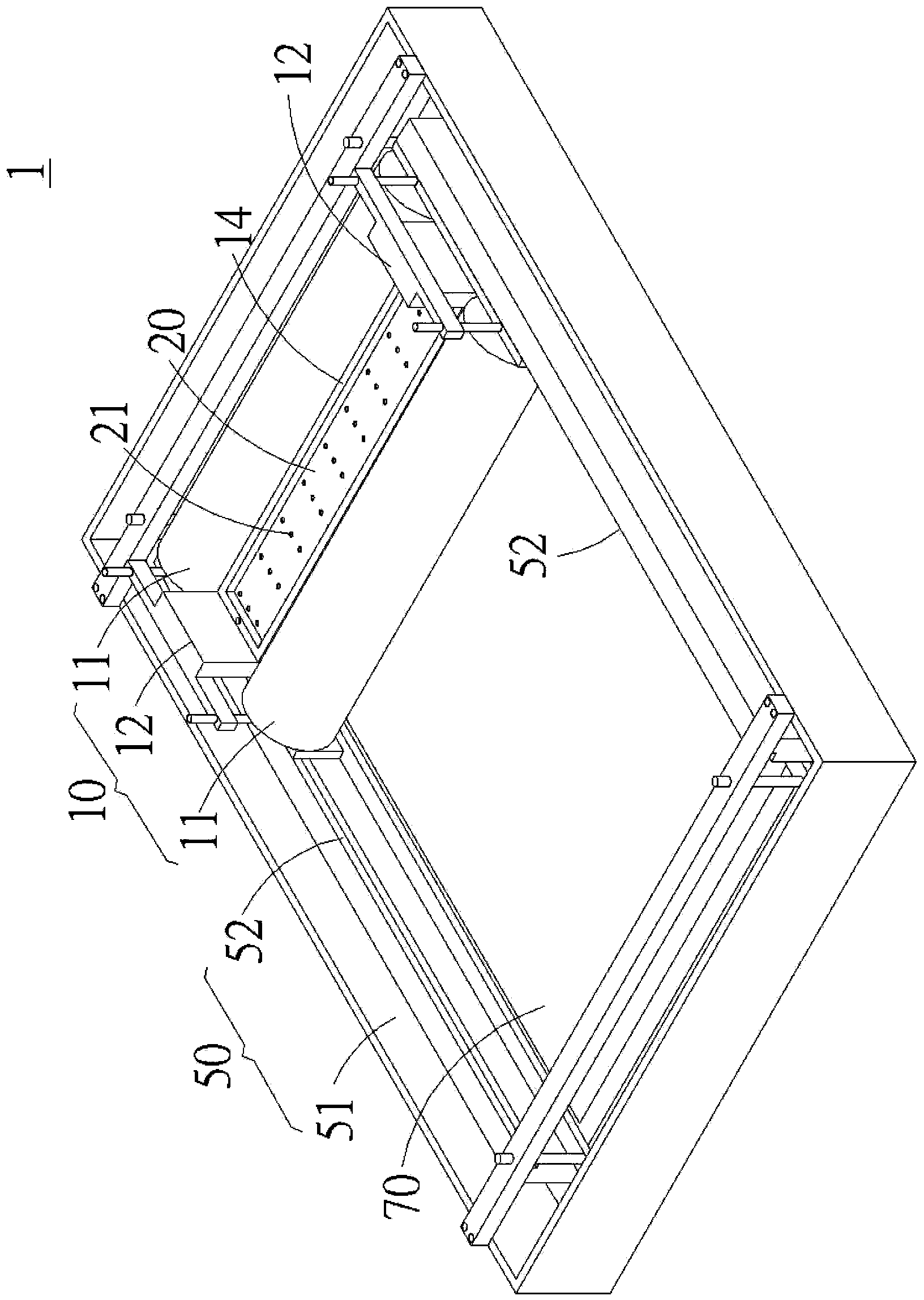

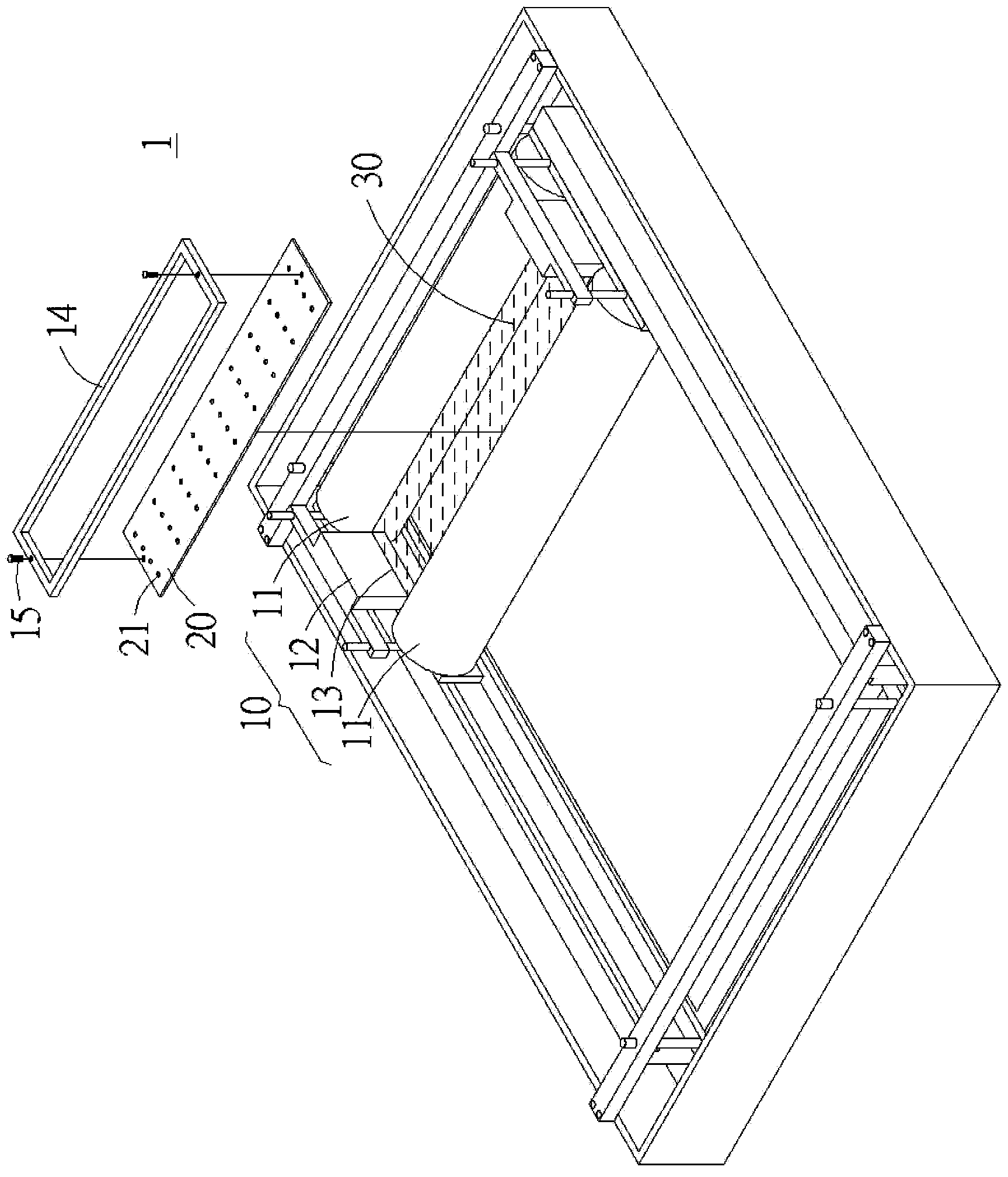

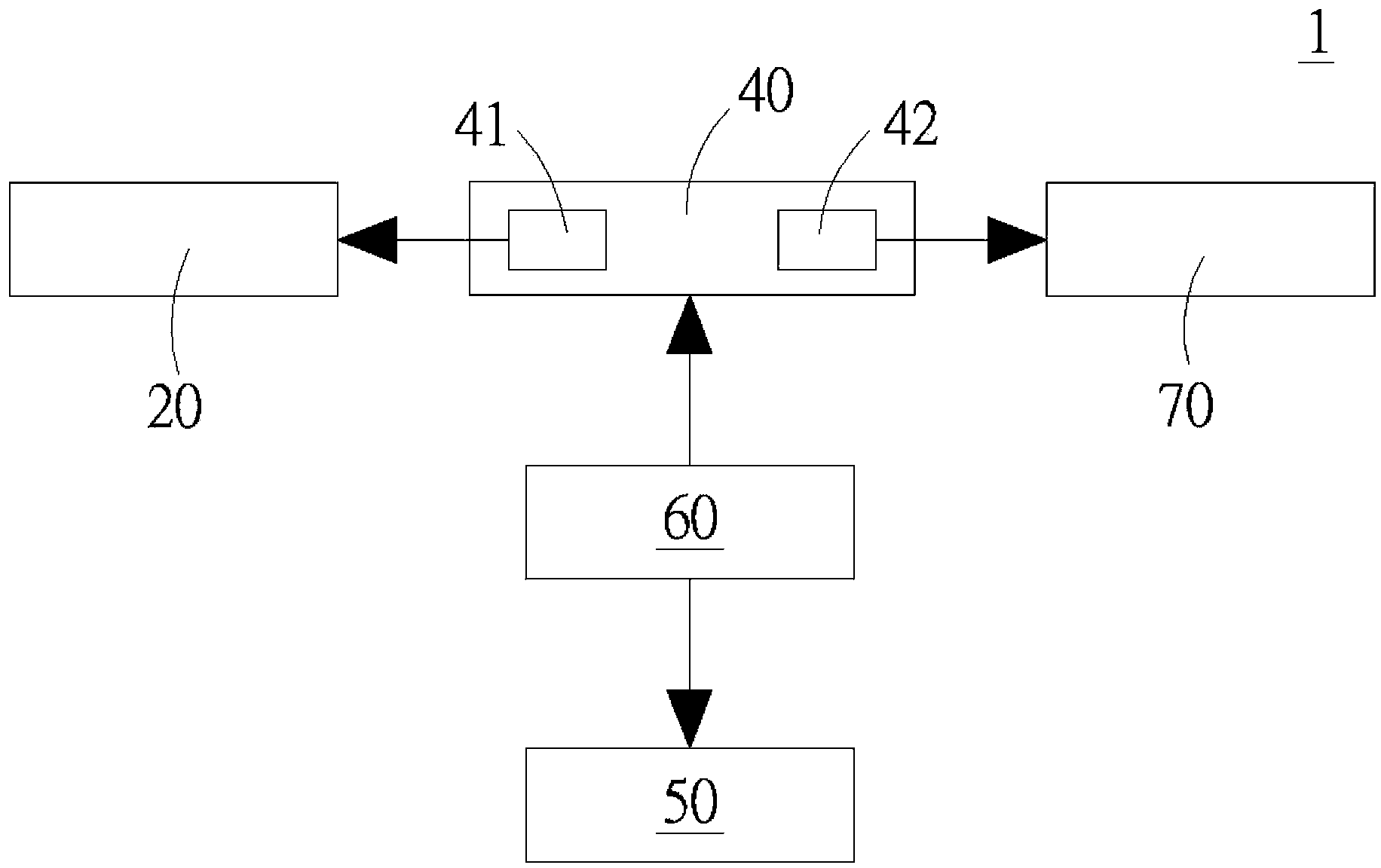

[0042] Such as figure 1 It is a perspective view of the structure of the electrochemical device of the present invention, figure 2 It is an exploded view of the structure of the electrochemical device of the present invention, and image 3 As shown in the structural diagram of the electrochemical device of the present invention, the electrochemical device 1 of the present invention at least includes: an electroplating tank module 10, an electrode plate 20, an electrolyte 30, a power supply module 40, a mobile module 50 and a control module Group 60.

[0043] Wherein: the electroplating tank module 10 is provided with two opposite cylinders 11 and two stoppers 12 respectively located between the two cylinders 11, and a working space 13 is surrounded by each cylinder 11 and the stoppers 12; and the electrode plate 20 and the electrolyte 30 is located in the working space 13. In the embodiment shown in the figure, the electroplating tank module 10 is further provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com