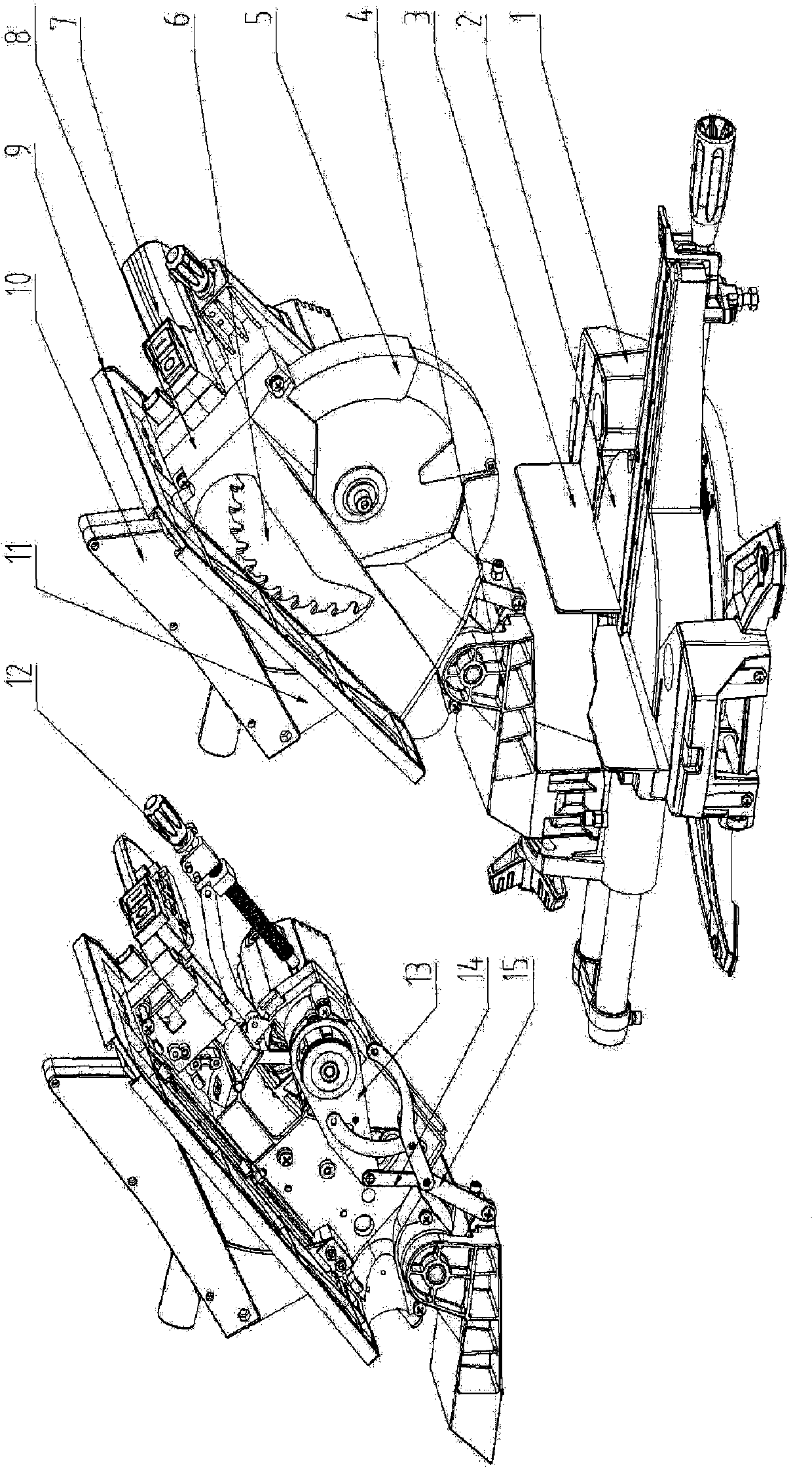

Combined saw

A compound saw and saw blade technology, applied in the field of cutting devices, can solve problems such as effective protection of saw blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

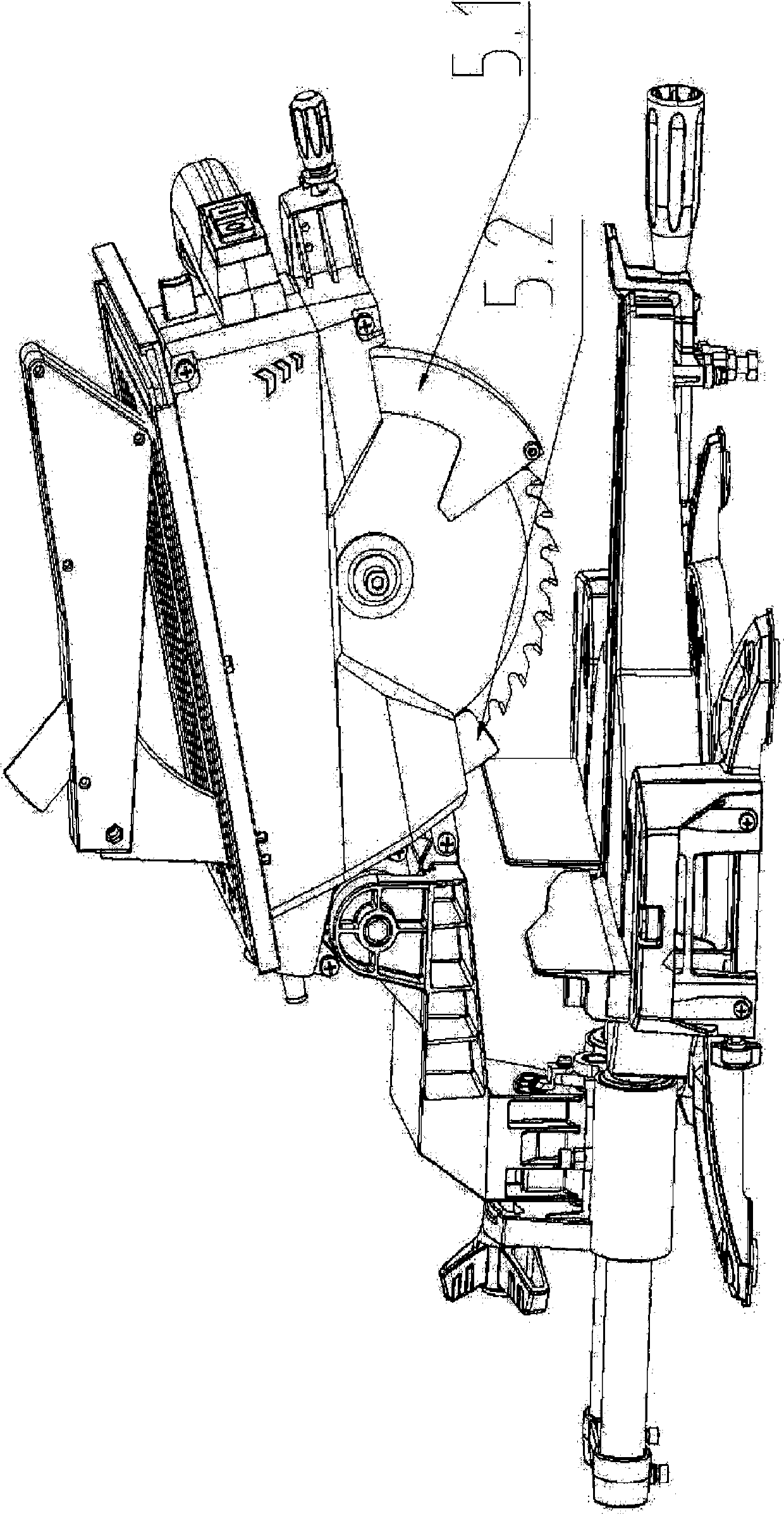

Embodiment 1

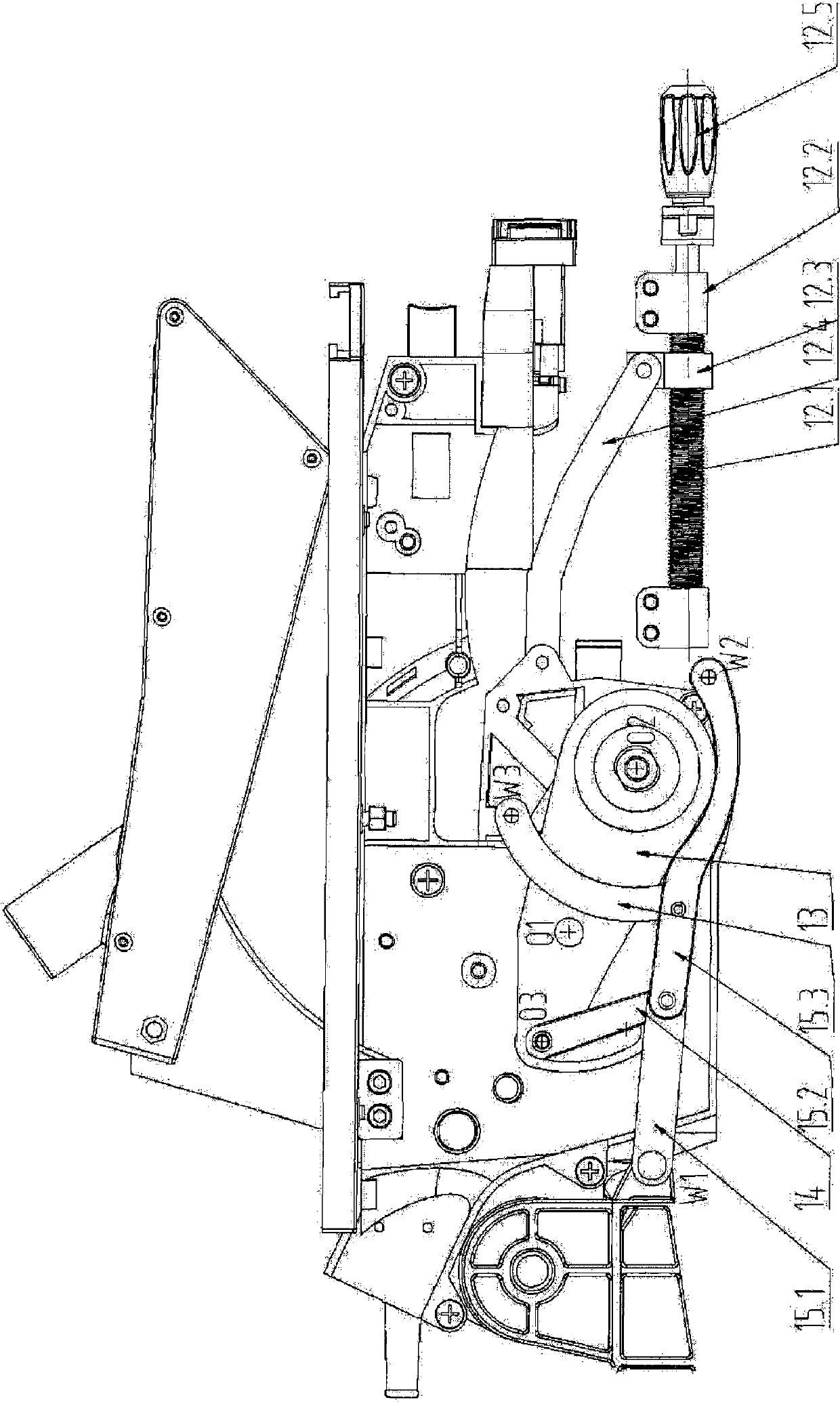

[0038] Such as Figure 2C with 3B As shown, the middle part of the saw blade lifting plate 13 is hinged at the point O1 on the frame, the saw blade (and its power and transmission components) 6 is installed on one end O2 of the saw blade lifting plate 13, and one end of the linkage rod 14 is hinged on the saw blade lifting The other end O3 of the plate 13, and the other end of the linkage rod 14 is hinged with the shield link assembly 15. The shield link assembly 15 is connected with the shield assembly 5 . The protective cover assembly 5 is sleeved on the saw blade (and its power and transmission assembly), and can swing around the same axis as the saw blade under the drive of the protective cover connecting rod assembly. When the saw blade lifting plate 13 swings relative to the frame, one end O2 and the other end O3 of the saw blade lifting plate 13 move in directions opposite to each other.

Embodiment 2

[0040] Such as Figure 5 As shown in A, one end O1 of the saw blade lifting plate 13" is hinged with the frame to become the axis of the saw blade lifting plate swing, and the saw blade (and its power and transmission components) is installed on the other end O2 of the saw blade lifting plate 13". On, one end of linkage rod 14 " is hinged at the point O3 between the points O1 and O2 on the saw blade lifting plate 13 ". The linkage rod 14 " is hinged on the frame by a hinge point O4 in the middle and then at the other end O5 and the shield link assembly 15 hinged, so that when the other end O5 of the linkage rod 14 " hinged with the shield linkage assembly 15 descends The points O2 and O3 on the lifting plate rise simultaneously, and when the other end O5 of the linkage rod and the protective cover link assembly hinged rises, the points O2 and O3 descend simultaneously.

Embodiment 3

[0042] Such as Figure 5 As shown in B, the saw blade lifting plate 13" is fixed on the fixed axis O2 or the fixed guide rail so that the saw blade lifting plate 13" can translate up and down relative to the frame, and the saw blade is installed on the fixed axis O2 or the fixed guide rail of the saw blade lifting plate 13". One end O3 of the linkage rod 14" is hinged on any point on the lifting plate. At this time, the linkage rod 14" is also hinged on the frame through a hinge point O4 in the middle, and then hinged at the other end O5 with the shield linkage assembly 15 , so that when the other end O5 of the linkage rod 14" hinged with the shield link assembly 15 descends, the points O2 and O3 on the lifting plate rise synchronously, and when the other end O5 hinged with the shield linkage assembly of the linkage rod rises, the point O2 and O3 fall synchronously.

[0043] Variation

[0044] Figure 2C The structure of the screw push rod shown is only an exemplary structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com