Liquid wiping-off device and ink-jet printing device

An ink jet printing device and liquid technology, applied in the direction of printing and the like, can solve the problems of shortening the contact time between the upper end and the wiper cleaner, insufficient cleaning of the wiper, etc., and achieve the effect of reliable cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]Hereinafter, an embodiment of the liquid wiping device of the present invention will be described in detail by taking an inkjet printing device including the liquid wiping device as an example.

[0039]

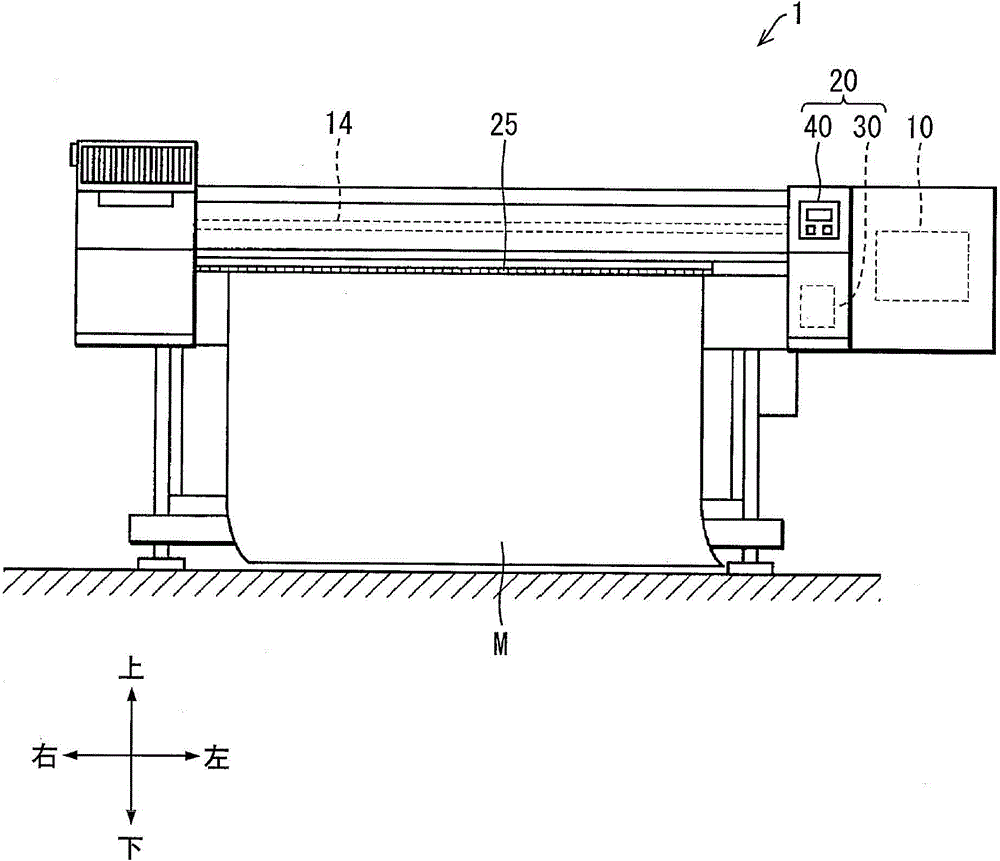

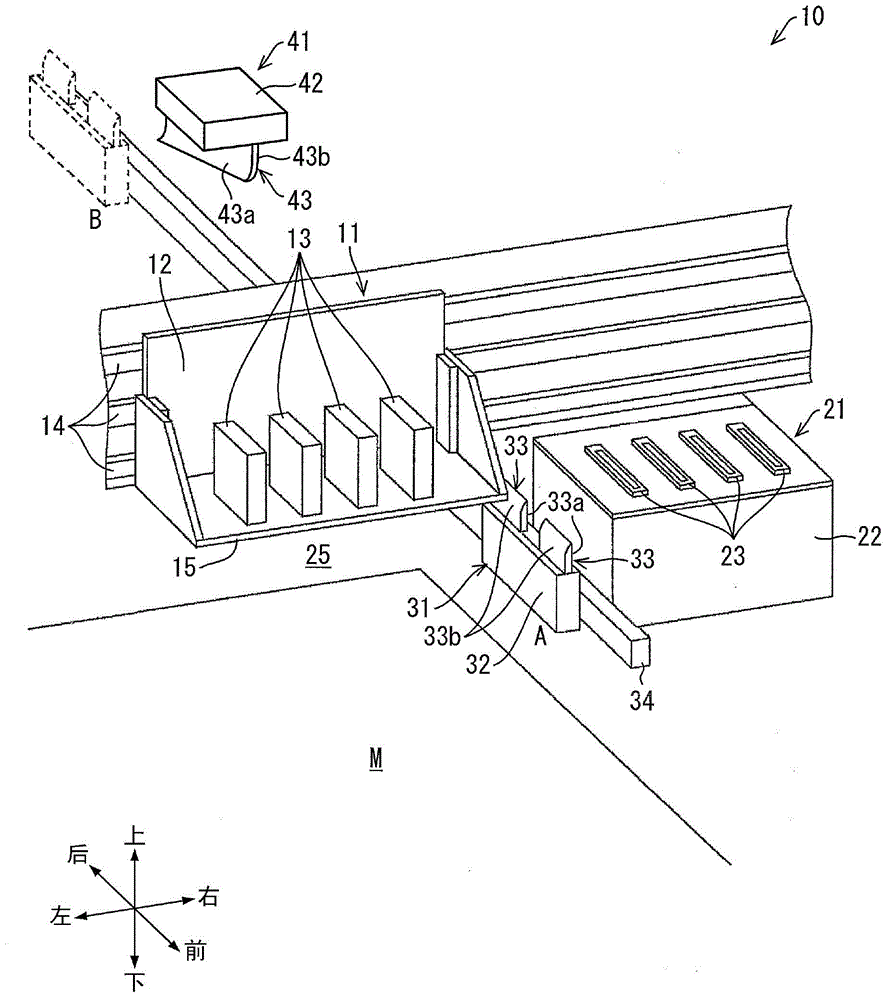

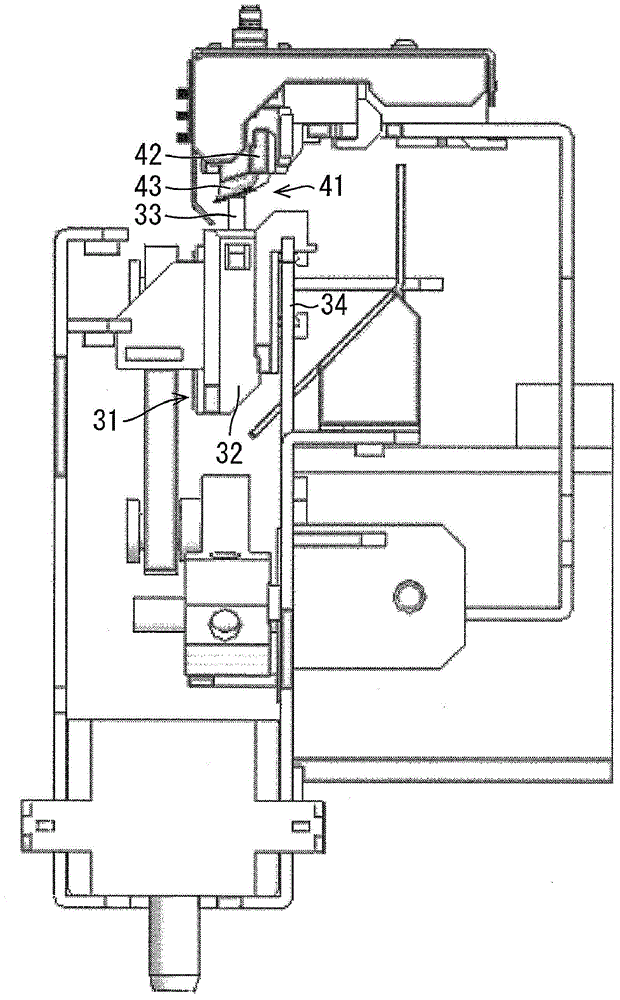

[0040] First, refer to Figure 1 ~ Figure 4 The inkjet printing device of this embodiment will be described. figure 1 is a front view of the inkjet printing device 1 . figure 2 It is a perspective view showing the printing unit 11 , the suction unit 21 , and the wiping unit 31 . in addition, image 3 as well as Figure 4 It is a perspective view which shows the wiping off part 31. In addition, in figure 2 In the drawings, each constituent member is simplified and shown for easy understanding of the drawings.

[0041] Such as figure 1 As shown, the inkjet printing apparatus 1 of the present embodiment has a printing unit 10 for printing on the recording medium M, and a control unit 20 for controlling the operation of each constituent member. Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com