Composite rare earth additive capable of improving thermal-fatigue-resistant performance of copper-aluminum based alloy

A technology for compounding rare earth and additives, applied in the field of copper alloys, can solve the problems of limited application scope and insufficient uniform performance, and achieve the effects of improving thermal fatigue performance, improving performance and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

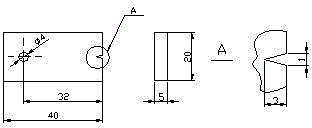

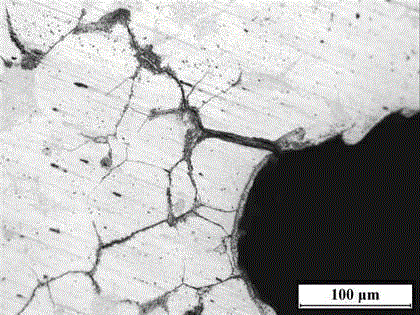

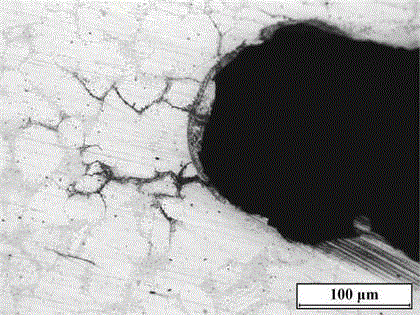

[0014] The thermal fatigue test was carried out using a resistance furnace heating self-constraining thermal fatigue testing machine. The plate-shaped sample is clamped on the four sides of the cube fixture to ensure that the heating and cooling positions of each sample are consistent, and the transmission device moves vertically up and down, so as to achieve automatic completion of sample heating and cooling. The temperature is measured and controlled by the thermocouple, the sample is heated and cooled between the room temperature of 20°C and 450°C, and the counter is used for automatic counting, and the furnace temperature is adjusted and maintained at 450°C, and the water temperature is 20°C (flowing tap water). Rapidly heat the sample, heating and cooling once as a cycle, the heating time of each cycle is 120s, and the cooling time in water is 5s, until the predetermined number of cycles. For the sample for studying thermal fatigue crack initiation, every cycle is 500 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com